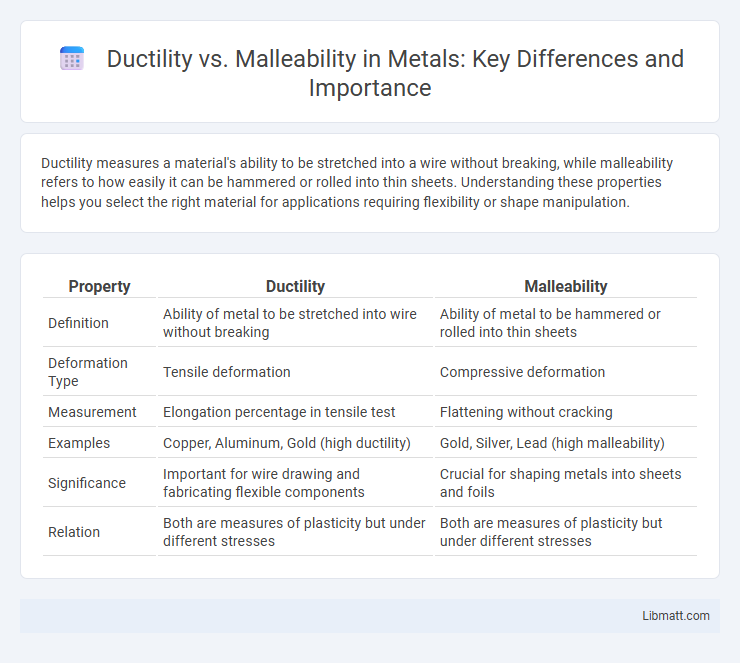

Ductility measures a material's ability to be stretched into a wire without breaking, while malleability refers to how easily it can be hammered or rolled into thin sheets. Understanding these properties helps you select the right material for applications requiring flexibility or shape manipulation.

Table of Comparison

| Property | Ductility | Malleability |

|---|---|---|

| Definition | Ability of metal to be stretched into wire without breaking | Ability of metal to be hammered or rolled into thin sheets |

| Deformation Type | Tensile deformation | Compressive deformation |

| Measurement | Elongation percentage in tensile test | Flattening without cracking |

| Examples | Copper, Aluminum, Gold (high ductility) | Gold, Silver, Lead (high malleability) |

| Significance | Important for wire drawing and fabricating flexible components | Crucial for shaping metals into sheets and foils |

| Relation | Both are measures of plasticity but under different stresses | Both are measures of plasticity but under different stresses |

Understanding Ductility and Malleability

Ductility and malleability are key physical properties that define how materials deform under stress; ductility measures a material's ability to stretch into wire without breaking, while malleability assesses how easily it can be hammered or rolled into thin sheets. Metals like gold and copper exhibit high ductility, making them ideal for electrical wiring, whereas malleability is crucial in applications requiring metal shaping, such as forging and rolling processes. Understanding these properties helps you select the right metal for manufacturing or engineering projects requiring specific deformation characteristics.

Definitions: What is Ductility?

Ductility refers to a material's ability to undergo significant plastic deformation under tensile stress without fracturing, allowing it to be stretched into thin wires. It is a key mechanical property in metals such as copper, aluminum, and gold, critical for manufacturing processes like wire drawing and metal forming. High ductility indicates enhanced flexibility and resilience, making materials suitable for applications requiring deformation without breaking.

Definitions: What is Malleability?

Malleability refers to a material's ability to deform under compressive stress, allowing it to be hammered or rolled into thin sheets without breaking. This property is crucial in metals like gold, silver, and copper, which can be shaped into various forms while maintaining structural integrity. Your understanding of malleability enhances material selection for applications requiring shaping processes such as forging and rolling.

Key Differences Between Ductility and Malleability

Ductility refers to a material's ability to be stretched into a wire without breaking, while malleability describes how easily a material can be hammered or rolled into thin sheets. Metals like copper exhibit high ductility, making them ideal for wiring applications, whereas gold demonstrates exceptional malleability, perfect for crafting intricate sheets. Understanding these key differences helps you select the right material based on whether your project requires tensile strength or compressive shaping.

Physical Properties Comparison

Ductility and malleability are both physical properties describing a material's ability to deform under stress without breaking; ductility refers to the capacity of a material, typically metals like copper or aluminum, to stretch into thin wires, while malleability is the ability of a material, such as gold or silver, to be hammered or rolled into thin sheets. The key distinction lies in the type of deformation: ductile materials undergo tensile stress and elongate, whereas malleable materials endure compressive stress and flatten. These properties depend on atomic structure and bonding, influencing their applications in manufacturing and engineering.

Examples of Ductile Materials

Copper, aluminum, and gold are prime examples of ductile materials widely used in electrical wiring and jewelry due to their ability to be stretched into thin wires without breaking. Steel and nickel also exhibit high ductility, important in manufacturing processes requiring extensive shaping and forming. These metals maintain structural integrity even when drawn into wires, distinguishing ductility from malleability, which refers to a material's ability to deform under compressive stress.

Examples of Malleable Materials

Copper, aluminum, and gold are prime examples of malleable materials frequently used in industrial applications due to their ability to be hammered or rolled into thin sheets without breaking. These metals exhibit high malleability because of their atomic structure, which allows layers of atoms to slide over each other easily under stress. Malleable materials like silver and lead are also essential in manufacturing processes where shaping and forming are required without compromising material integrity.

Industrial Applications: When Ductility Matters

Ductility plays a critical role in industrial applications where materials undergo significant tensile stress, such as in the manufacturing of wires, cables, and structural components. Your choice of ductile metals like copper or aluminum ensures reliability and performance in electrical wiring and construction, as these materials can be stretched without breaking. In contrast, malleability is more relevant in processes involving compressive forces, like metal forging or sheet metal work.

Industrial Applications: When Malleability Matters

Malleability is critical in industries such as metal forming, where materials like gold and aluminum are shaped into sheets or complex components without cracking. This property enables manufacturing processes like rolling, hammering, and pressing, essential for producing automotive panels, packaging foils, and architectural elements. Compared to ductility, malleability specifically ensures metals can withstand compressive forces during shaping, making it vital for applications requiring thin, durable metal layers.

Conclusion: Choosing Materials Based on Properties

Selecting materials based on ductility and malleability depends on the specific application requirements; ductile materials excel in applications needing extensive stretching such as wire drawing, while malleable materials are preferred for processes like hammering or rolling into thin sheets. Understanding the mechanical behavior of a metal under tensile and compressive forces informs the optimal choice, ensuring durability and performance in manufacturing or structural uses. Engineers prioritize ductility for flexibility and malleability for shape adaptation, aligning material properties with functional demands.

Ductility vs malleability Infographic

libmatt.com

libmatt.com