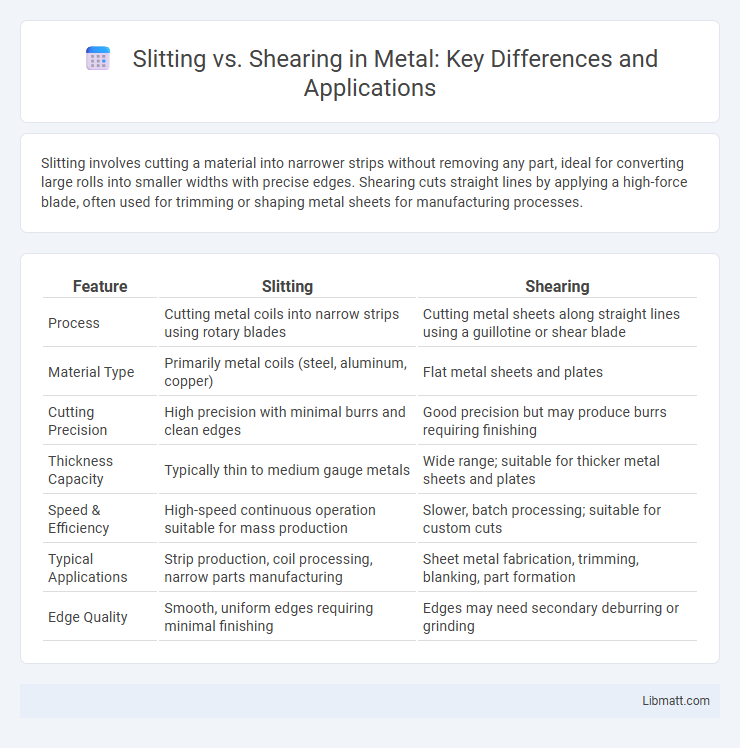

Slitting involves cutting a material into narrower strips without removing any part, ideal for converting large rolls into smaller widths with precise edges. Shearing cuts straight lines by applying a high-force blade, often used for trimming or shaping metal sheets for manufacturing processes.

Table of Comparison

| Feature | Slitting | Shearing |

|---|---|---|

| Process | Cutting metal coils into narrow strips using rotary blades | Cutting metal sheets along straight lines using a guillotine or shear blade |

| Material Type | Primarily metal coils (steel, aluminum, copper) | Flat metal sheets and plates |

| Cutting Precision | High precision with minimal burrs and clean edges | Good precision but may produce burrs requiring finishing |

| Thickness Capacity | Typically thin to medium gauge metals | Wide range; suitable for thicker metal sheets and plates |

| Speed & Efficiency | High-speed continuous operation suitable for mass production | Slower, batch processing; suitable for custom cuts |

| Typical Applications | Strip production, coil processing, narrow parts manufacturing | Sheet metal fabrication, trimming, blanking, part formation |

| Edge Quality | Smooth, uniform edges requiring minimal finishing | Edges may need secondary deburring or grinding |

Introduction to Slitting and Shearing

Slitting and shearing are precise metal cutting processes used in manufacturing and fabrication industries to shape materials according to specifications. Slitting involves cutting a wide coil of metal into narrower strips using rotary knives, ideal for producing uniform widths with minimal waste. Shearing cuts metal sheets into specific shapes or sizes using a straight blade, making it suitable for clean, straight cuts on flat materials tailored to Your production needs.

Defining Slitting: Process and Applications

Slitting is a precision metalworking process that involves cutting large rolls of material into narrower strips using rotary blades, primarily applied in industries like packaging, automotive, and electronics. This technique enhances material utilization and improves production efficiency by enabling customized widths without altering the entire coil. Slitting is essential for converting materials such as steel, aluminum, and plastic films into sizes suitable for further manufacturing or assembly operations.

Understanding Shearing: Process and Uses

Shearing is a metal cutting process that involves applying a high force to cut a sheet or plate along a straight line without generating chips or burning the material. It is commonly used in manufacturing industries to create blanks or trim edges of metal sheets, ensuring precise dimensions and clean edges. This method is efficient for producing large volumes of parts with consistent quality, especially in steel, aluminum, and other metal fabrication applications.

Core Differences Between Slitting and Shearing

Slitting involves cutting a material into narrower strips using rotary knives, primarily for continuous processing of thin materials like metal coils or paper rolls. Shearing, on the other hand, uses straight blades to cut materials in a single action, suitable for producing flat blanks or sheets with precise straight edges. The core difference lies in slitting's continuous, strip-focused cutting versus shearing's single, straight-cutting motion for individual pieces.

Material Suitability for Slitting vs Shearing

Slitting is ideal for thin, flexible materials such as metal coils, plastic films, and paper which require precise width cuts without distorting the material. Shearing suits thicker, rigid materials like sheet metal, where straight cuts with minimal deformation are necessary. Your choice between slitting and shearing depends on the material thickness, flexibility, and the desired cut quality.

Equipment and Tools Comparison

Slitting equipment typically includes rotary blades mounted on a shaft, designed to cut large rolls of material into narrower strips efficiently, while shearing tools use straight blades to produce clean, straight cuts on sheet metals. Slitting machines often offer greater speed and precision for continuous processing, whereas shearing equipment provides higher cutting force suitable for thicker, rigid materials. Your choice depends on material type, thickness, and production volume, with slitting favored for webs and coils and shearing preferred for flat plates and heavy sheets.

Advantages of Slitting Techniques

Slitting techniques offer precise, clean cuts with minimal material waste, making them highly efficient for processing thin metals, plastics, and paper. This method enhances production speed while maintaining high-quality edges, reducing the need for additional finishing. Optimizing your manufacturing process with slitting improves cost-effectiveness and material utilization compared to shearing.

Benefits and Limitations of Shearing

Shearing offers precise cutting for sheet metals with minimal material waste and high edge quality, making it ideal for straight cuts in industrial applications. It enables fast processing speeds while maintaining consistent dimensions, but it is limited by the maximum material thickness and can cause deformation or burr formation on edges. Maintenance of blades and equipment cost are additional factors impacting the practicality of shearing in large-scale manufacturing.

Choosing the Right Method: Key Considerations

Choosing between slitting and shearing depends on material thickness, edge quality requirements, and production speed. Slitting is ideal for cutting thin coils and producing narrow strips with minimal edge distortion, while shearing suits thicker materials and straight cuts with clean edges. Evaluating operational costs, equipment capabilities, and the intended application ensures optimal method selection.

Industry Applications and Real-World Examples

Slitting excels in industries requiring precise width adjustments of metal coils, such as automotive manufacturing for producing body panels and electronics for circuit board components. Shearing is widely used in construction and fabrication for cutting large metal sheets into specific shapes and sizes, like steel beams and metal roofing panels. Your choice between slitting and shearing depends on the material form, precision needs, and final application requirements.

Slitting vs shearing Infographic

libmatt.com

libmatt.com