Powder coated finishes provide a thick, durable protective layer resistant to chipping and corrosion, ideal for outdoor metal surfaces, while anodized coatings offer a thinner, more natural oxide layer that enhances corrosion resistance and wear without obscuring the metal's texture. Your choice depends on whether you prioritize a tougher, colored finish or a subtle, corrosion-resistant enhancement that maintains the metal's appearance.

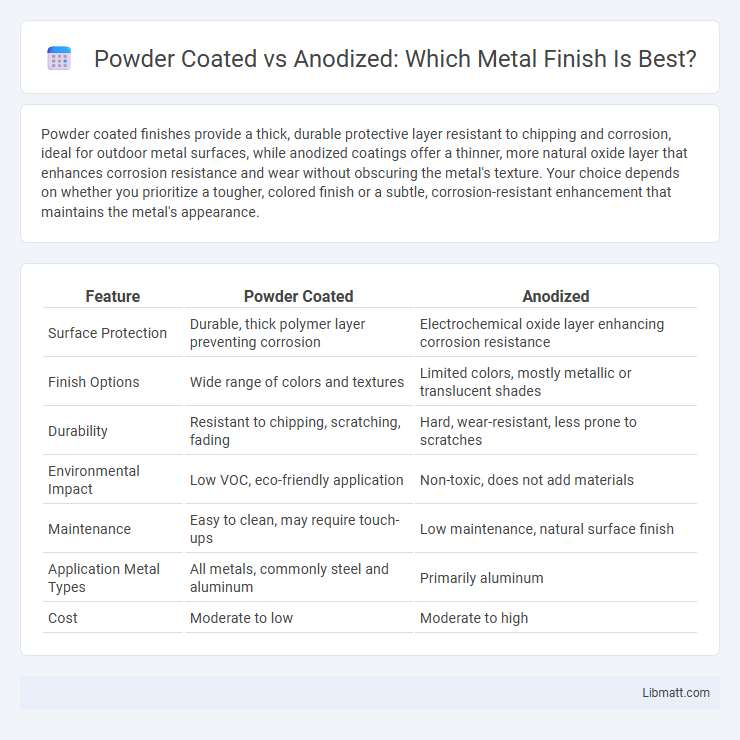

Table of Comparison

| Feature | Powder Coated | Anodized |

|---|---|---|

| Surface Protection | Durable, thick polymer layer preventing corrosion | Electrochemical oxide layer enhancing corrosion resistance |

| Finish Options | Wide range of colors and textures | Limited colors, mostly metallic or translucent shades |

| Durability | Resistant to chipping, scratching, fading | Hard, wear-resistant, less prone to scratches |

| Environmental Impact | Low VOC, eco-friendly application | Non-toxic, does not add materials |

| Maintenance | Easy to clean, may require touch-ups | Low maintenance, natural surface finish |

| Application Metal Types | All metals, commonly steel and aluminum | Primarily aluminum |

| Cost | Moderate to low | Moderate to high |

Introduction to Surface Finishes

Powder coated and anodized surfaces offer distinct protective and aesthetic benefits for metals, with powder coating providing a thick, durable layer of polymer resin for enhanced corrosion resistance and vibrant color options. Anodizing, an electrochemical process, forms a thin oxide layer that improves metal hardness and resists wear while maintaining a natural metallic appearance. Understanding the differences in durability, finish quality, and environmental resistance helps you select the ideal surface finish for your specific application needs.

What is Powder Coating?

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto a metal surface, then cured under heat to form a durable, protective layer. This coating provides superior resistance to corrosion, chipping, fading, and wear compared to conventional paint. Understanding powder coating can help you choose the best surface treatment for your metal products, especially when durability and appearance are critical.

What is Anodizing?

Anodizing is an electrochemical process that enhances the natural oxide layer on aluminum surfaces, increasing corrosion resistance, durability, and aesthetic appeal. Unlike powder coating, anodizing penetrates the metal itself, creating a permanent protective layer that cannot chip or peel. Your aluminum components benefit from improved hardness and color stability through anodizing, making it ideal for outdoor and high-wear applications.

Key Differences: Powder Coating vs Anodizing

Powder coating creates a thick, durable, and colorful finish by applying and baking a dry powder, ideal for corrosion resistance and vibrant aesthetics on metal surfaces. Anodizing, an electrochemical process, enhances aluminum by forming a thin, hard oxide layer that increases corrosion resistance and surface hardness while maintaining a metallic appearance. Your choice depends on whether you prioritize thickness and color options (powder coating) or enhanced durability with a natural metal look (anodizing).

Durability and Longevity Comparison

Powder coating provides a thick, durable layer resistant to chipping, scratching, and fading, making it ideal for outdoor applications where longevity is crucial. Anodizing creates a hard anodic oxide layer directly on the aluminum, enhancing corrosion resistance and wear protection while maintaining a thin, lightweight finish. Both methods extend the lifespan of metal surfaces effectively, but powder coating excels in impact resistance, whereas anodizing offers superior protection against corrosion and UV damage.

Aesthetic Options and Color Choices

Powder coated finishes offer a vast range of vibrant colors and textures, providing extensive customization for your projects. Anodized surfaces feature more subtle, metallic tones with limited color options but excel in enhancing natural aluminum aesthetics. Choosing between powder coated and anodized depends on whether you prioritize bold color variety or sleek, durable metallic finishes.

Environmental Impact and Sustainability

Powder coating generates fewer volatile organic compounds (VOCs) and produces less hazardous waste compared to traditional liquid paints, making it an eco-friendlier option. Anodizing is highly sustainable due to its process that enhances aluminum durability without harmful emissions, and it allows the metal to be fully recyclable at the end of its life cycle. Your choice between powder coated and anodized finishes can significantly influence the environmental footprint of your project, with anodizing often preferred for long-term sustainability.

Cost Analysis: Powder Coating vs Anodizing

Powder coating typically offers a lower initial cost compared to anodizing, making it a budget-friendly option for large-scale projects. Anodizing, while generally more expensive due to its complex electrochemical process, provides superior durability and corrosion resistance, which can reduce long-term maintenance costs. You should weigh upfront expenses against lifecycle benefits when deciding between powder coated and anodized finishes.

Typical Applications and Use Cases

Powder coated finishes are commonly applied in automotive parts, outdoor furniture, and architectural structures due to their durability and wide color range. Anodized coatings are typically used in aerospace components, electronics, and consumer goods like smartphones and kitchen appliances for enhanced corrosion resistance and aesthetic appeal. Both finishes improve product longevity but serve distinct purposes based on environmental exposure and functional requirements.

Choosing the Right Finish for Your Needs

Powder coated finishes provide a durable, corrosion-resistant surface ideal for outdoor use and heavy-duty applications, offering a wide range of colors and textures. Anodized finishes create a hard, wear-resistant oxide layer on aluminum, enhancing scratch resistance and maintaining a sleek, metallic appearance. Your choice depends on whether you prioritize color variety and impact resistance (powder coating) or superior surface hardness and conductive properties (anodizing).

powder coated vs anodized Infographic

libmatt.com

libmatt.com