Pickled steel undergoes an acid bath to remove mill scale, resulting in a clean surface ideal for subsequent coatings or painting, while oiled steel is coated with a light layer of oil to prevent rust during storage and transport. Your choice depends on whether you prioritize a bare, clean finish for processing or corrosion protection before use.

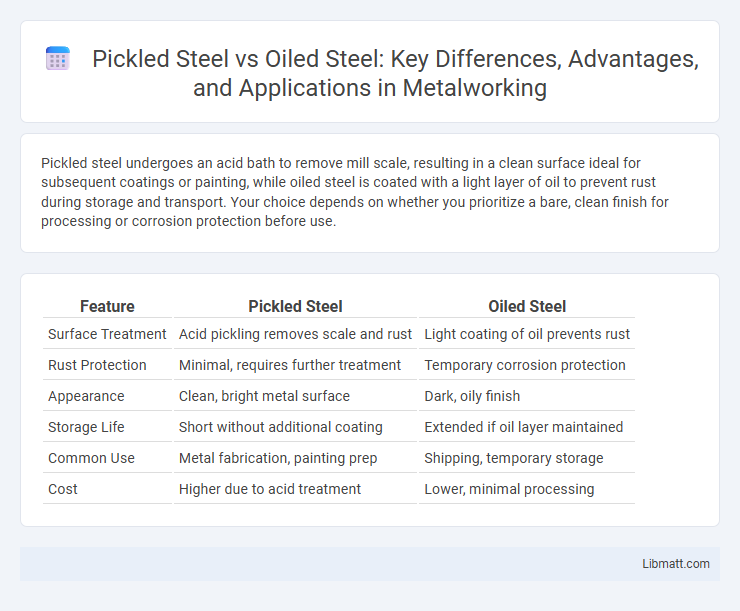

Table of Comparison

| Feature | Pickled Steel | Oiled Steel |

|---|---|---|

| Surface Treatment | Acid pickling removes scale and rust | Light coating of oil prevents rust |

| Rust Protection | Minimal, requires further treatment | Temporary corrosion protection |

| Appearance | Clean, bright metal surface | Dark, oily finish |

| Storage Life | Short without additional coating | Extended if oil layer maintained |

| Common Use | Metal fabrication, painting prep | Shipping, temporary storage |

| Cost | Higher due to acid treatment | Lower, minimal processing |

Introduction to Pickled Steel and Oiled Steel

Pickled steel undergoes an acid bath to remove mill scale, rust, and impurities, resulting in a smooth, clean surface ideal for precision manufacturing and paint adhesion. Oiled steel features a thin layer of oil applied after cold rolling to prevent oxidation during storage and transportation, enhancing corrosion resistance and surface quality. Your choice between pickled and oiled steel depends on the required surface finish, corrosion protection needs, and subsequent processing steps.

What is Pickled Steel?

Pickled steel is steel that has undergone an acid treatment process to remove surface impurities such as mill scale, rust, and oxidation, resulting in a clean, smooth finish ideal for further processing or coating. This process enhances your steel's surface quality by improving paint adhesion and corrosion resistance compared to oiled steel, which retains a protective oil coating to prevent rust during storage. Using pickled steel is essential when precise surface conditions are required for manufacturing or finishing applications.

What is Oiled Steel?

Oiled steel is a type of steel coated with a thin layer of protective oil to prevent rust and corrosion during storage and transportation. This oil acts as a barrier against moisture and contaminants, preserving the metal's surface integrity. Commonly used in industrial and manufacturing settings, oiled steel ensures durability and ease of handling before further processing or fabrication.

Manufacturing Processes: Pickling vs. Oiling

Pickled steel undergoes an acid pickling process that removes rust, scale, and impurities from the metal surface, enhancing surface cleanliness and preparing it for further processing or coating. In contrast, oiled steel involves applying a protective layer of oil or lubricant immediately after cold rolling to prevent corrosion and reduce friction during handling and forming. The pickling process emphasizes surface preparation through chemical treatment, while oiling prioritizes corrosion protection and mechanical lubrication.

Surface Quality and Appearance Differences

Pickled steel features a clean, smooth surface with a bright, matte finish due to the acid treatment removing mill scale and impurities, enhancing its aesthetic appeal and paint adhesion. Oiled steel retains a darker, slightly textured surface with a thin oil coating to prevent rust, often appearing less uniform and more industrial. Your choice depends on whether you prioritize a visually pristine finish or protective, maintenance-friendly qualities.

Corrosion Resistance: Pickled Steel vs. Oiled Steel

Pickled steel offers superior corrosion resistance due to the removal of mill scale and surface impurities, which enhances the adhesion of protective coatings and reduces rust formation. Oiled steel relies on a thin layer of oil to act as a barrier against moisture and oxygen, but this protection can degrade over time, leading to potential oxidation. For long-term durability in corrosive environments, pickled steel provides a more reliable base for advanced protective treatments compared to the temporary shielding effect of oil.

Applications and Industry Uses

Pickled steel is extensively used in industries such as automotive, construction, and manufacturing due to its smooth, clean surface that enhances paint adhesion and reduces corrosion. Oiled steel finds applications in environments where temporary rust protection is needed during storage or shipping, making it ideal for hardware, electrical components, and machinery parts. Your choice depends on whether the application requires a clean, treated surface or a protective coating to prevent oxidation before further processing.

Cost Comparison and Economic Considerations

Pickled steel generally incurs higher initial costs due to the acid cleaning process, which requires specialized equipment and handling measures. Oiled steel offers a more cost-effective option by applying a protective oil layer that reduces corrosion without extensive processing, leading to lower production expenses. From an economic standpoint, oiled steel proves advantageous for large-volume applications where budget constraints prioritize affordability over enhanced surface finish.

Environmental Impact and Safety Factors

Pickled steel involves an acid bath process that generates hazardous waste, requiring proper disposal to reduce environmental harm, while oiled steel uses less chemically intensive methods, resulting in a lower ecological footprint. The residual acids and by-products from pickling pose safety risks to workers, including chemical burns and respiratory issues, whereas oiled steel primarily presents slip hazards due to the oil coating. Choosing oiled steel aligns better with sustainable manufacturing practices and safer handling conditions in industrial applications.

Choosing the Right Steel: Pickled or Oiled?

Pickled steel undergoes an acid bath process that removes mill scale and rust, resulting in a clean, bright surface ideal for painting or coating applications, enhancing adhesion and corrosion resistance. Oiled steel retains a thin film of protective oil, preventing oxidation during storage and transport, making it suitable for applications where immediate processing or further finishing occurs. Selecting between pickled or oiled steel depends on your production needs: pickled steel offers better surface quality for finishing, while oiled steel provides rust protection for longer storage periods.

pickled steel vs oiled steel Infographic

libmatt.com

libmatt.com