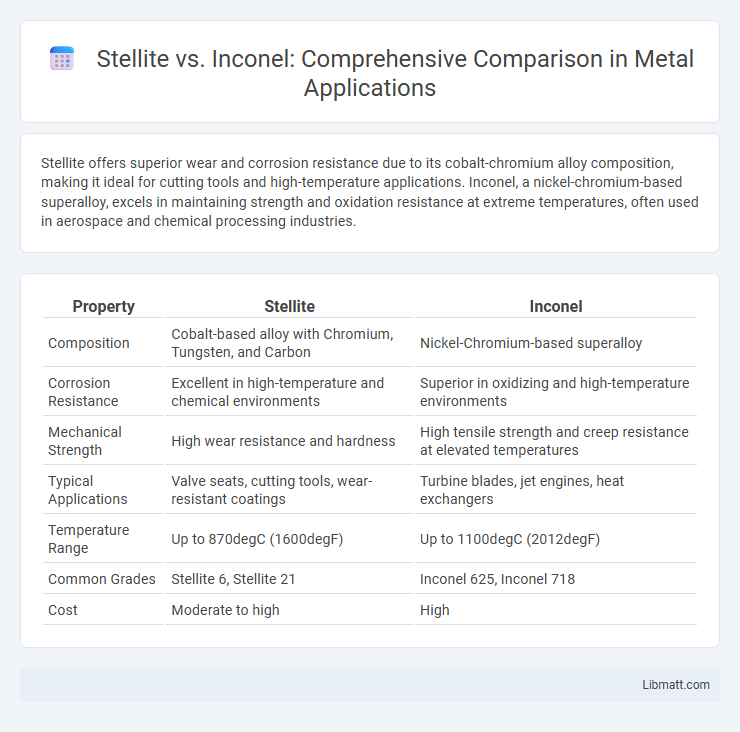

Stellite offers superior wear and corrosion resistance due to its cobalt-chromium alloy composition, making it ideal for cutting tools and high-temperature applications. Inconel, a nickel-chromium-based superalloy, excels in maintaining strength and oxidation resistance at extreme temperatures, often used in aerospace and chemical processing industries.

Table of Comparison

| Property | Stellite | Inconel |

|---|---|---|

| Composition | Cobalt-based alloy with Chromium, Tungsten, and Carbon | Nickel-Chromium-based superalloy |

| Corrosion Resistance | Excellent in high-temperature and chemical environments | Superior in oxidizing and high-temperature environments |

| Mechanical Strength | High wear resistance and hardness | High tensile strength and creep resistance at elevated temperatures |

| Typical Applications | Valve seats, cutting tools, wear-resistant coatings | Turbine blades, jet engines, heat exchangers |

| Temperature Range | Up to 870degC (1600degF) | Up to 1100degC (2012degF) |

| Common Grades | Stellite 6, Stellite 21 | Inconel 625, Inconel 718 |

| Cost | Moderate to high | High |

Introduction to Stellite and Inconel

Stellite is a cobalt-chromium alloy known for exceptional wear resistance, corrosion resistance, and hardness, commonly used in cutting tools and hardfacing applications. Inconel comprises nickel-chromium-based superalloys prized for outstanding high-temperature strength and oxidation resistance, ideal for aerospace and gas turbine components. Both materials offer unique properties tailored to extreme environments, making them critical in industries requiring durability and performance.

Chemical Composition Comparison

Stellite alloys primarily consist of cobalt with varying amounts of chromium, tungsten, and carbon, offering exceptional wear and corrosion resistance. Inconel is a nickel-chromium-based superalloy, notable for its high nickel content combined with iron, chromium, and smaller quantities of molybdenum or niobium, providing excellent oxidation resistance and high-temperature strength. Understanding these distinct chemical compositions helps you select the optimal material for applications requiring either extreme hardness or heat resistance.

Mechanical Properties Overview

Stellite alloys, primarily cobalt-based, exhibit exceptional wear resistance, high hardness, and superior strength at elevated temperatures, making them ideal for cutting tools and tribological applications. Inconel, a nickel-chromium-based superalloy, excels in oxidation and corrosion resistance while maintaining excellent mechanical strength and creep resistance under extreme thermal environments. Both materials demonstrate high tensile strength and hardness, but Stellite outperforms in wear resistance, whereas Inconel is preferred for applications requiring prolonged exposure to high temperatures and corrosive settings.

Corrosion Resistance Performance

Stellite alloys offer exceptional corrosion resistance due to their high chromium and cobalt content, making them ideal for severe chemical environments. Inconel, a nickel-chromium-based superalloy, excels in resisting oxidation and corrosion at extreme temperatures, particularly in aerospace and marine applications. Your choice between Stellite and Inconel should consider specific environmental factors, such as temperature and chemical exposure, to ensure optimal corrosion resistance performance.

Temperature Resistance Capabilities

Stellite alloys exhibit exceptional temperature resistance, maintaining hardness and corrosion resistance up to approximately 900degC (1650degF), making them ideal for high-temperature wear-resistant applications. Inconel, a nickel-chromium-based superalloy, outperforms Stellite by withstanding temperatures up to 1150degC (2100degF) while preserving strength and oxidation resistance, especially in harsh environments like gas turbines and jet engines. Your choice between Stellite and Inconel for temperature resistance depends on the specific thermal demands and mechanical stresses of your application.

Common Industrial Applications

Stellite alloys are widely used in aerospace, cutting tools, and valve seats due to their exceptional wear resistance and hardness under high temperatures. Inconel alloys excel in chemical processing, marine engineering, and gas turbines because of their outstanding corrosion resistance and strength in extreme environments. Your choice between Stellite and Inconel depends on the specific industrial demands for durability, temperature tolerance, and corrosion resistance.

Wear and Erosion Resistance

Stellite alloys exhibit superior wear and erosion resistance due to their high hardness and cobalt-based matrix, making them ideal for applications involving abrasive and impact conditions. Inconel, a nickel-chromium-based superalloy, offers excellent resistance to high-temperature oxidation and corrosion but generally has lower wear resistance compared to Stellite. Your choice between Stellite and Inconel should consider the specific wear and erosion demands of your operating environment to maximize component longevity.

Machinability and Fabrication

Stellite alloys offer excellent wear resistance but present challenges in machinability due to their hardness and tendency to work harden, requiring specialized tooling and slower cutting speeds during fabrication. Inconel alloys, known for their high strength and corrosion resistance, exhibit better machinability compared to Stellite but still demand careful control of cutting parameters and tool materials to avoid rapid tool wear. When choosing between Stellite and Inconel for your project, consider the balance between their machinability constraints and the desired performance in the final application.

Cost and Availability Analysis

Stellite alloys, known for their exceptional wear resistance and high-temperature strength, generally come at a higher cost compared to Inconel due to their cobalt-based composition. Inconel, a nickel-chromium alloy, offers greater availability and cost-efficiency, making it a preferred choice for applications requiring corrosion resistance and oxidation stability. Your decision between Stellite and Inconel should consider budget constraints and material availability in your specific industry or project location.

Choosing Between Stellite and Inconel

Choosing between Stellite and Inconel depends on your specific application requirements, including corrosion resistance, temperature tolerance, and mechanical strength. Stellite alloys excel in wear resistance and oxidation protection at high temperatures, making them ideal for cutting tools and valve components. Inconel offers superior performance in extreme environments with exceptional resistance to oxidation and corrosion, especially in aerospace and chemical processing industries.

Stellite vs Inconel Infographic

libmatt.com

libmatt.com