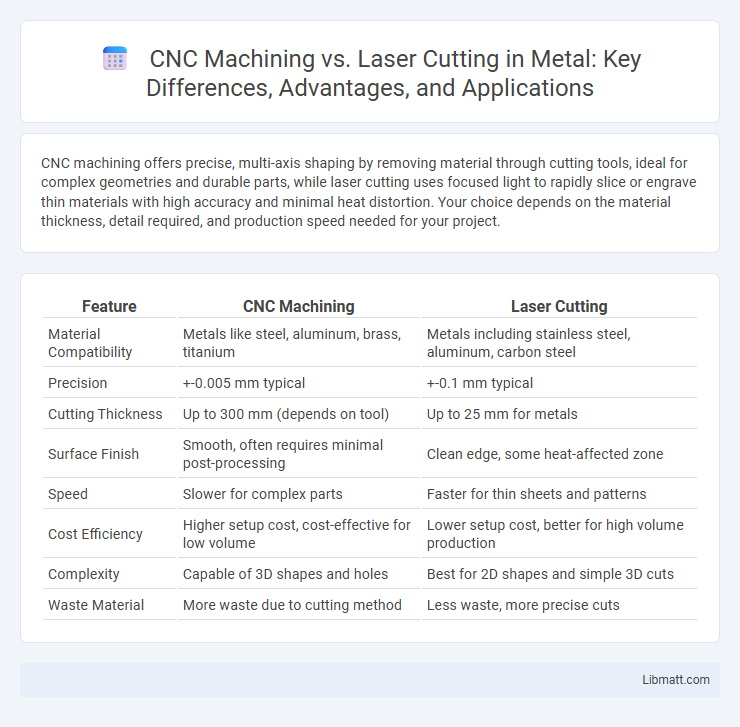

CNC machining offers precise, multi-axis shaping by removing material through cutting tools, ideal for complex geometries and durable parts, while laser cutting uses focused light to rapidly slice or engrave thin materials with high accuracy and minimal heat distortion. Your choice depends on the material thickness, detail required, and production speed needed for your project.

Table of Comparison

| Feature | CNC Machining | Laser Cutting |

|---|---|---|

| Material Compatibility | Metals like steel, aluminum, brass, titanium | Metals including stainless steel, aluminum, carbon steel |

| Precision | +-0.005 mm typical | +-0.1 mm typical |

| Cutting Thickness | Up to 300 mm (depends on tool) | Up to 25 mm for metals |

| Surface Finish | Smooth, often requires minimal post-processing | Clean edge, some heat-affected zone |

| Speed | Slower for complex parts | Faster for thin sheets and patterns |

| Cost Efficiency | Higher setup cost, cost-effective for low volume | Lower setup cost, better for high volume production |

| Complexity | Capable of 3D shapes and holes | Best for 2D shapes and simple 3D cuts |

| Waste Material | More waste due to cutting method | Less waste, more precise cuts |

Introduction to CNC Machining and Laser Cutting

CNC machining utilizes computer-controlled precision tools to remove material from a workpiece, offering high accuracy and repeatability for complex shapes and tight tolerances. Laser cutting employs focused laser beams to cut or engrave materials with exceptional speed and minimal thermal distortion, ideal for fine, intricate designs on thin metals and plastics. Your choice between CNC machining and laser cutting depends on factors such as material type, thickness, design complexity, and production volume.

How CNC Machining Works

CNC machining works by using computer-controlled machines to remove material from a solid block through precise cutting, drilling, or milling processes. This technique offers high accuracy and repeatability, making it ideal for complex geometries and durable parts in metals, plastics, and composites. Your choice between CNC machining and laser cutting depends on the required material thickness, detail, and production volume.

How Laser Cutting Works

Laser cutting operates by directing a high-powered laser beam through optics and computer numerical control (CNC) systems to precisely cut or engrave materials. The laser melts, burns, or vaporizes the targeted area, creating clean edges with minimal thermal distortion. Its ability to cut metals, plastics, wood, and fabrics with exceptional accuracy makes laser cutting ideal for intricate designs and rapid prototyping compared to traditional CNC machining.

Material Compatibility Comparison

CNC machining excels with metals, plastics, and wood, offering precise cuts on harder materials like aluminum and steel, while laser cutting is ideal for thinner, non-metallic materials such as acrylic, fabric, and paper. Your choice depends on material thickness and type; laser cutting delivers clean edges on softer substances, whereas CNC machining handles tougher, thicker components with complex geometries. Both processes offer distinct advantages in material compatibility, influencing manufacturing efficiency and final product quality.

Precision and Tolerances

CNC machining offers exceptional precision with tolerances often within +-0.005 mm, making it ideal for complex parts requiring tight dimensional accuracy. Laser cutting provides high precision as well, typically maintaining tolerances around +-0.1 mm, which suits applications involving thin materials and intricate patterns. The choice between the two depends on the required tolerance level and material thickness, with CNC machining preferred for harsher tolerance demands.

Speed and Efficiency

CNC machining offers precise material removal with consistent speed, optimized for complex geometries and thicker materials, maintaining efficiency in small to medium production runs. Laser cutting excels in high-speed processing of thin sheets, delivering intricate cuts with minimal material waste and setup time, making it ideal for rapid prototyping and large-scale manufacturing. Both methods maximize operational efficiency by reducing manual intervention, but laser cutting generally surpasses CNC machining in throughput for fine, high-volume tasks.

Surface Finish and Edge Quality

CNC machining delivers superior surface finish and edge quality through precise material removal, producing smooth, consistent surfaces ideal for intricate details and tight tolerances. Laser cutting achieves sharp, clean edges with minimal burring, especially on thin materials, but may require post-processing for thicker or reflective surfaces to enhance finish quality. Your choice depends on material type and project specifications, balancing CNC's uniformity with laser cutting's speed and edge precision.

Cost Considerations

CNC machining typically involves higher upfront costs due to expensive tooling and machine setup, but offers cost efficiency for complex parts and low to medium production volumes. Laser cutting generally provides lower initial expenses and faster processing times, making it more cost-effective for thin materials and high-volume orders. Material waste and precision requirements also heavily impact overall costs in both manufacturing methods.

Common Applications of Each Method

CNC machining excels in producing complex, precise parts like automotive components, aerospace parts, and custom metal prototypes that require detailed 3D shaping and tight tolerances. Laser cutting is ideal for quick and accurate cutting of sheet metal, plastics, and wood used in signage, decorative designs, and electronic enclosures. Your choice between CNC machining and laser cutting depends on the material thickness, desired precision, and project complexity.

Choosing the Right Technology for Your Project

CNC machining offers precise material removal ideal for complex 3D parts, while laser cutting excels in high-speed, intricate 2D designs on thin materials. Your project's material type, thickness, and required tolerances determine the optimal choice between these technologies. Selecting CNC machining ensures durability and versatility, whereas laser cutting provides faster turnaround and fine edge quality.

CNC machining vs laser cutting Infographic

libmatt.com

libmatt.com