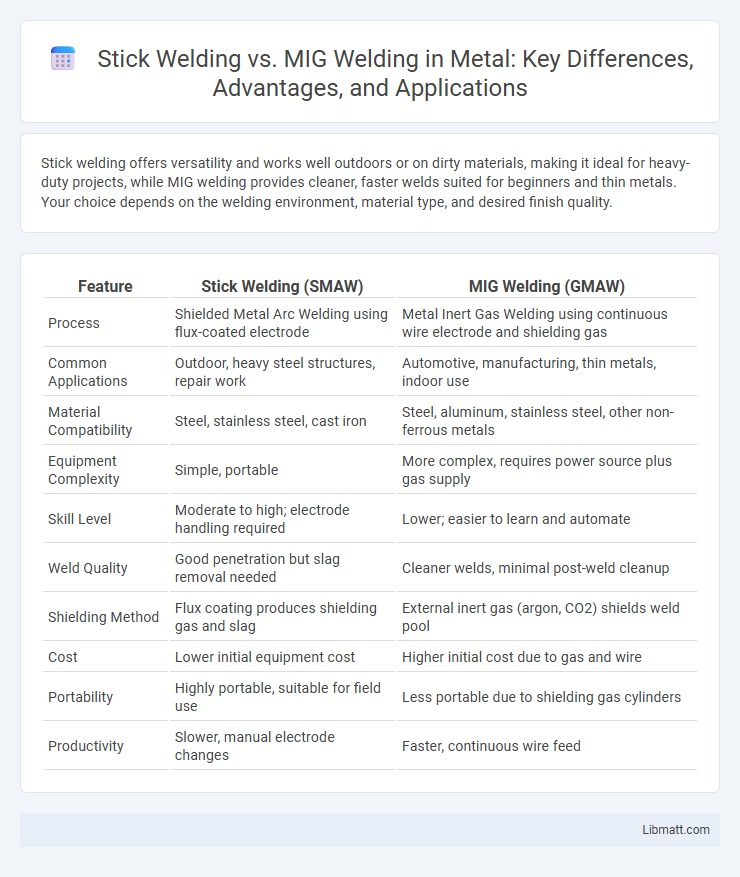

Stick welding offers versatility and works well outdoors or on dirty materials, making it ideal for heavy-duty projects, while MIG welding provides cleaner, faster welds suited for beginners and thin metals. Your choice depends on the welding environment, material type, and desired finish quality.

Table of Comparison

| Feature | Stick Welding (SMAW) | MIG Welding (GMAW) |

|---|---|---|

| Process | Shielded Metal Arc Welding using flux-coated electrode | Metal Inert Gas Welding using continuous wire electrode and shielding gas |

| Common Applications | Outdoor, heavy steel structures, repair work | Automotive, manufacturing, thin metals, indoor use |

| Material Compatibility | Steel, stainless steel, cast iron | Steel, aluminum, stainless steel, other non-ferrous metals |

| Equipment Complexity | Simple, portable | More complex, requires power source plus gas supply |

| Skill Level | Moderate to high; electrode handling required | Lower; easier to learn and automate |

| Weld Quality | Good penetration but slag removal needed | Cleaner welds, minimal post-weld cleanup |

| Shielding Method | Flux coating produces shielding gas and slag | External inert gas (argon, CO2) shields weld pool |

| Cost | Lower initial equipment cost | Higher initial cost due to gas and wire |

| Portability | Highly portable, suitable for field use | Less portable due to shielding gas cylinders |

| Productivity | Slower, manual electrode changes | Faster, continuous wire feed |

Introduction to Stick Welding and MIG Welding

Stick welding, also known as Shielded Metal Arc Welding (SMAW), uses a consumable electrode coated in flux to create an electric arc, ideal for outdoor and heavy-duty metal fabrication. MIG welding, or Gas Metal Arc Welding (GMAW), employs a continuous wire electrode and an inert gas shield, offering faster welding speeds and cleaner welds for thin metals and automotive applications. Both methods provide unique advantages in terms of portability, weld quality, and material compatibility.

Core Principles of Stick Welding

Stick welding, also known as shielded metal arc welding (SMAW), operates on the principle of using a consumable electrode coated with flux that melts during welding, creating a protective gas and slag to shield the weld pool from contamination. The electric arc generated between the electrode and the workpiece provides the necessary heat to melt both the electrode and the base metal, forming a strong bond as they cool. This process is versatile for outdoor and heavy-duty applications, offering portability and compatibility with various metals and thicknesses.

Core Principles of MIG Welding

MIG welding operates on the principle of feeding a continuous solid wire electrode through a welding gun into the weld pool, shielded by an inert gas such as argon or a mix of argon and CO2 to prevent oxidation. The process relies on an electric arc generated between the wire electrode and the workpiece, which melts the wire and base metal to form a strong, clean weld. MIG welding is highly efficient for welding thin to medium thickness metals with minimal spatter and excellent control over weld bead appearance.

Equipment and Setup Differences

Stick welding uses a consumable electrode coated with flux, requiring a simpler power supply and minimal additional equipment, making it ideal for outdoor or rugged environments. MIG welding employs a continuous wire feed and shielding gas, necessitating a wire feeder, gas cylinder, and more complex setup for precise control and clean welds. The equipment complexity and setup time for MIG welding are higher compared to the more portable and straightforward stick welding apparatus.

Weld Quality and Appearance

Stick welding produces strong, durable welds suitable for heavy materials but often results in rougher, slag-covered surfaces requiring post-weld cleaning. MIG welding delivers cleaner, aesthetically smoother welds with minimal spatter, making it ideal for thin metals and visible projects. Weld quality in stick welding excels in outdoor or rusty conditions, while MIG welding offers superior appearance and consistent bead profiles in controlled environments.

Versatility Across Materials and Environments

Stick welding offers exceptional versatility across various materials, including steel, stainless steel, and cast iron, and performs reliably outdoors or in windy conditions due to its flux-coated electrodes. MIG welding excels with thin metals such as aluminum and mild steel, providing high-speed, clean welds primarily in controlled indoor environments. Both methods have distinct advantages depending on material type and environmental factors, making them essential for diverse welding applications.

Cost Comparison: Initial and Ongoing Expenses

Stick welding offers a lower initial cost due to inexpensive equipment and consumables, making it accessible for beginners and small-scale projects. MIG welding requires a higher upfront investment for the welder and gas supply but provides lower ongoing costs through increased efficiency and less frequent electrode replacement. Your choice depends on balancing budget constraints with project volume and precision needs.

Learning Curve and Skill Requirements

Stick welding demands a steeper learning curve due to its manual electrode handling and requires strong control of arc length and angle for quality welds. MIG welding offers a gentler learning curve with its wire feed system, making it more accessible for beginners while still requiring skill for precise speed and torch movement. Proficiency in stick welding is often favored in outdoor or rugged conditions, whereas MIG welding suits indoor environments and projects needing consistent, clean welds.

Best Applications for Stick and MIG Welding

Stick welding excels in outdoor environments and heavy-duty construction projects due to its tolerance for dirt, rust, and weather conditions, making it ideal for pipeline work, shipbuilding, and repair jobs. MIG welding is best suited for indoor applications requiring clean, precise welds on thin to medium gauge metals, such as automotive work, manufacturing, and home DIY projects. Your choice depends on factors like material type, environment, and weld quality needed for the task.

Choosing the Right Welding Method for Your Needs

Stick welding offers superior performance for outdoor, heavy-duty, and rusty metal projects due to its portability and ability to create strong welds in challenging conditions. MIG welding provides higher speed, cleaner welds, and easier operation, making it ideal for beginners and indoor work on thin metals. Assess your project's environment, material type, and skill level to select the welding method that best suits your needs and ensures optimal results.

Stick Welding vs MIG Welding Infographic

libmatt.com

libmatt.com