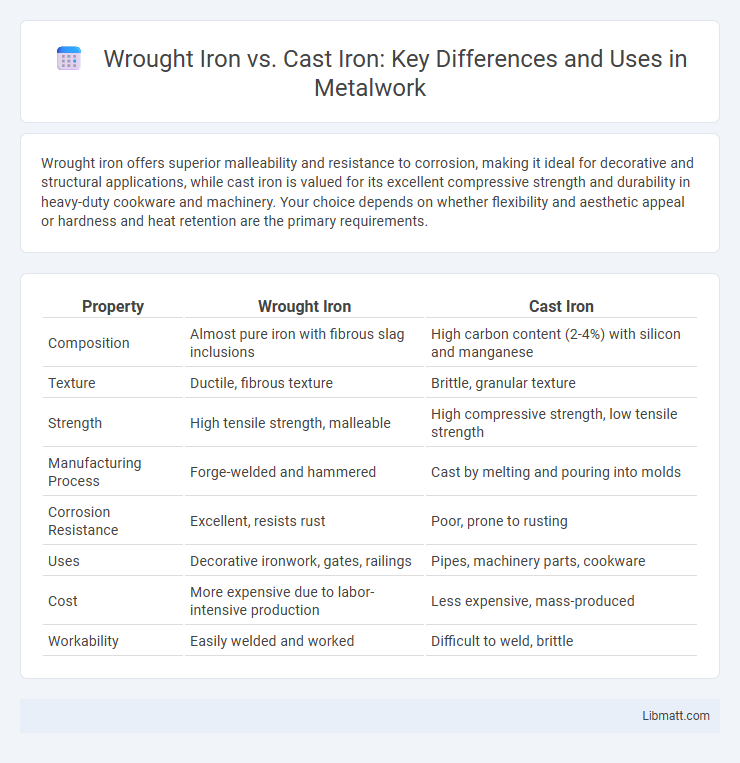

Wrought iron offers superior malleability and resistance to corrosion, making it ideal for decorative and structural applications, while cast iron is valued for its excellent compressive strength and durability in heavy-duty cookware and machinery. Your choice depends on whether flexibility and aesthetic appeal or hardness and heat retention are the primary requirements.

Table of Comparison

| Property | Wrought Iron | Cast Iron |

|---|---|---|

| Composition | Almost pure iron with fibrous slag inclusions | High carbon content (2-4%) with silicon and manganese |

| Texture | Ductile, fibrous texture | Brittle, granular texture |

| Strength | High tensile strength, malleable | High compressive strength, low tensile strength |

| Manufacturing Process | Forge-welded and hammered | Cast by melting and pouring into molds |

| Corrosion Resistance | Excellent, resists rust | Poor, prone to rusting |

| Uses | Decorative ironwork, gates, railings | Pipes, machinery parts, cookware |

| Cost | More expensive due to labor-intensive production | Less expensive, mass-produced |

| Workability | Easily welded and worked | Difficult to weld, brittle |

Introduction to Wrought Iron and Cast Iron

Wrought iron is a malleable and ductile alloy primarily composed of iron with minute carbon content, known for its toughness and resistance to corrosion, making it ideal for decorative gates and furniture. Cast iron, containing higher carbon levels, is brittle but excels in compressive strength, commonly used in heavy-duty applications like engine blocks and cookware. Understanding the differences between wrought iron's flexibility and cast iron's hardness can help you choose the right material for your project.

Historical Background and Development

Wrought iron, known for its fibrous texture and malleability, was widely used during the Industrial Revolution for tools, weapons, and architecture, dating back to ancient civilizations. Cast iron, characterized by its brittleness and high carbon content, became prominent in the 18th century with advancements in blast furnace technology, enabling mass production of durable cookware, pipes, and machinery parts. The development of these irons reflects significant technological progress in metallurgy, shaping infrastructure and manufacturing industries for centuries.

Composition and Material Properties

Wrought iron consists primarily of pure iron with a very low carbon content, typically less than 0.08%, resulting in a tough, ductile material with fibrous inclusions of slag that enhance corrosion resistance and malleability. Cast iron contains 2-4% carbon along with silicon, manganese, and trace elements, making it hard and brittle due to its high carbon content forming cementite and graphite structures. The composition differences yield wrought iron's superior tensile strength and weldability, while cast iron excels in compressive strength and castability but is prone to fracture under tension.

Manufacturing Processes Compared

Wrought iron undergoes repeated heating and mechanical working, such as hammering and rolling, to remove impurities and achieve its fibrous texture, while cast iron is produced by melting pig iron and pouring it into molds to solidify. The forging and shaping of wrought iron result in higher ductility and malleability, contrasting with cast iron's brittle, high-carbon composition formed through rapid cooling. These distinct manufacturing processes influence their structural properties, with wrought iron suited for decorative and load-bearing applications and cast iron favored for heavy-duty, compressive environments.

Physical Appearance and Surface Texture

Wrought iron features a fibrous, grainy texture with visible slag inclusions, giving it a rough, irregular surface that enhances its decorative appeal. Cast iron exhibits a smooth, brittle surface due to its high carbon content and casting process, often showing fine, grainy patterns under close inspection. The distinct physical appearances result from different manufacturing methods, influencing both visual aesthetics and tactile sensations.

Strength, Durability, and Flexibility

Wrought iron exhibits superior flexibility and tensile strength due to its fibrous structure, making it resistant to cracking under stress, while cast iron is brittle but excels in compressive strength and hardness. Durability-wise, wrought iron is highly corrosion-resistant and can endure outdoor conditions longer without rusting, whereas cast iron is more prone to rust if not properly protected. The choice between wrought iron and cast iron depends on application demands for structural resilience, impact resistance, and exposure to environmental factors.

Corrosion Resistance and Maintenance

Wrought iron offers superior corrosion resistance compared to cast iron due to its fibrous structure and lower carbon content, making it less prone to rust and easier to maintain over time. Cast iron, while strong and durable, is more susceptible to rust without regular protective coatings and requires frequent upkeep to prevent corrosion damage. Understanding these differences can help you choose the best material for your outdoor projects to minimize maintenance efforts and extend longevity.

Cost and Availability

Wrought iron typically commands a higher price due to its labor-intensive manufacturing process and limited production, making it less readily available compared to cast iron. Cast iron benefits from widespread industrial production, resulting in lower costs and greater accessibility for construction and manufacturing projects. When budget constraints and availability are critical, cast iron often serves as the more economical and practical choice.

Common Applications and Uses

Wrought iron is commonly used in decorative gates, fences, railings, and furniture due to its malleability and resistance to corrosion. Cast iron finds applications in heavy-duty cookware, pipes, automotive engine blocks, and machinery components because of its high compressive strength and excellent wear resistance. Both materials play crucial roles in construction and manufacturing, with wrought iron favored for ornamental work and cast iron preferred for structural and industrial purposes.

Choosing the Right Iron for Your Project

Wrought iron offers superior malleability and corrosion resistance, making it ideal for decorative projects requiring intricate designs and durability. Cast iron, known for its exceptional compressive strength and heat retention, suits applications like cookware, pipes, and heavy-duty machinery components. Assess your project's strength, flexibility, and aesthetic needs carefully to determine whether wrought iron's malleability or cast iron's robustness best serves your purpose.

Wrought Iron vs Cast Iron Infographic

libmatt.com

libmatt.com