Sheet metal stamping shapes metal sheets by pressing them into specific forms using dies, ideal for producing flat or moderately contoured parts with high precision and efficiency. Deep drawing involves pulling a metal blank into a die to create complex, hollow, and cylindrical shapes, making it perfect for manufacturing automotive panels, kitchen sinks, and aerospace components.

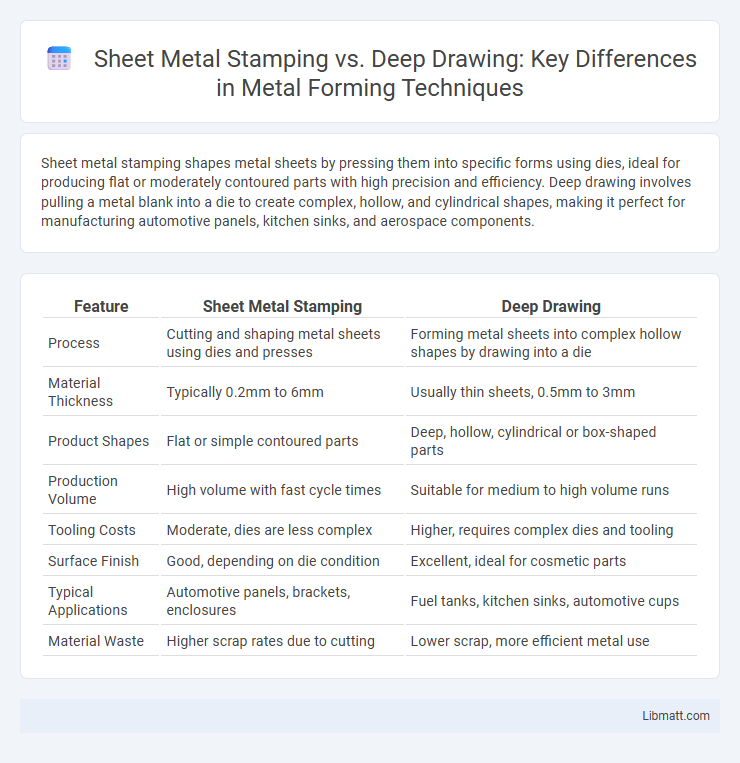

Table of Comparison

| Feature | Sheet Metal Stamping | Deep Drawing |

|---|---|---|

| Process | Cutting and shaping metal sheets using dies and presses | Forming metal sheets into complex hollow shapes by drawing into a die |

| Material Thickness | Typically 0.2mm to 6mm | Usually thin sheets, 0.5mm to 3mm |

| Product Shapes | Flat or simple contoured parts | Deep, hollow, cylindrical or box-shaped parts |

| Production Volume | High volume with fast cycle times | Suitable for medium to high volume runs |

| Tooling Costs | Moderate, dies are less complex | Higher, requires complex dies and tooling |

| Surface Finish | Good, depending on die condition | Excellent, ideal for cosmetic parts |

| Typical Applications | Automotive panels, brackets, enclosures | Fuel tanks, kitchen sinks, automotive cups |

| Material Waste | Higher scrap rates due to cutting | Lower scrap, more efficient metal use |

Introduction to Sheet Metal Stamping and Deep Drawing

Sheet metal stamping and deep drawing are essential manufacturing processes used to shape metal sheets into specific forms with high precision. Sheet metal stamping involves cutting, bending, or shaping metal sheets using a press and dies, making it ideal for producing flat or shallow components. Deep drawing, a subset of metal forming, focuses on creating deeper, hollow shapes by stretching the metal sheet into a die cavity, enabling the production of complex parts with greater depth and structural integrity.

Core Processes: Stamping vs Deep Drawing

Sheet metal stamping involves cutting, bending, and shaping metal sheets into desired forms using a press and dies, primarily focusing on surface deformation and precision cutting. Deep drawing, a subset of stamping, specifically transforms flat metal sheets into complex, hollow shapes by stretching the material into a die cavity with a punch. While stamping addresses a broad range of forming operations including embossing and blanking, deep drawing specializes in creating seamless, high-depth components like automotive panels and kitchen sinks.

Material Selection: Suitability for Each Method

Sheet metal stamping is ideal for materials with good ductility and moderate thickness, such as aluminum, brass, and mild steel, allowing precise and fast production of flat or moderately curved parts. Deep drawing requires materials with excellent formability and high elongation capacity, like low carbon steel, stainless steel, and certain aluminum alloys, to withstand significant deformation without cracking. Material choice directly influences process efficiency and final part quality in both stamping and deep drawing operations.

Tooling and Equipment Differences

Sheet metal stamping uses flat dies and simpler press machines for cutting and shaping metal sheets, while deep drawing requires more complex, multi-part dies and hydraulic presses to draw metal into three-dimensional shapes. You need robust tooling in deep drawing processes to handle higher forces and precise metal flow control, unlike the relatively straightforward tooling designed for stamping operations. Equipment for deep drawing often includes blank holders and ejectors for part removal, which aren't typically necessary in standard sheet metal stamping.

Production Speed and Efficiency Comparison

Sheet metal stamping offers faster production speeds due to its simplicity in shaping flat metal sheets through pressing and cutting, making it ideal for high-volume runs with consistent dimensions. Deep drawing involves pulling metal sheets into complex, deeper shapes, requiring longer cycle times and more precise control, which can reduce overall throughput compared to stamping. Efficiency in stamping is higher for shallow parts with repetitive patterns, while deep drawing is preferred for intricate, three-dimensional geometries despite slower production rates.

Cost Analysis: Stamping vs Deep Drawing

Sheet metal stamping generally offers lower production costs for high-volume runs due to faster cycle times and simpler tooling, making it more cost-effective for flat or shallow parts. Deep drawing incurs higher initial expenses because of complex dies and slower processes but is preferable for manufacturing intricate, three-dimensional components with greater depth. Your choice depends on balancing upfront tooling investment against per-piece production costs and the geometric complexity of the part.

Typical Applications in Industry

Sheet metal stamping is widely used in automotive manufacturing for producing large volumes of parts such as brackets, panels, and chassis components due to its high precision and speed. Deep drawing is favored in the production of complex, hollow parts like fuel tanks, kitchen sinks, and beverage cans, where significant metal deformation without thinning is essential. Both processes are integral in electronics, aerospace, and appliance industries, with stamping suited for flat parts and deep drawing for three-dimensional shapes.

Advantages and Limitations of Each Process

Sheet metal stamping offers high-speed production and cost-effectiveness for large volumes, making it ideal for parts with simple to moderately complex shapes. Deep drawing excels at creating complex, seamless hollow parts with excellent structural integrity but requires longer cycle times and higher tooling costs. Your choice depends on balancing part complexity, production volume, and budget constraints between stamping's efficiency and deep drawing's precision.

Quality, Precision, and Tolerances

Sheet metal stamping offers high-quality production with excellent precision for parts requiring consistent flatness and repetitive shapes, while deep drawing excels in forming complex, three-dimensional geometries with superior structural integrity. Tolerances in stamping are typically tighter, often within +-0.1 mm, making it ideal for applications demanding exact dimensions, whereas deep drawing tolerances may vary between +-0.2 mm to +-0.5 mm, accommodating thicker materials and deeper parts. Your choice between these processes should consider the required dimensional accuracy, complexity of design, and the material thickness to ensure optimal part quality and performance.

Choosing the Right Method for Your Project

Selecting the appropriate metal forming process depends on factors such as part complexity, volume, and material thickness. Sheet metal stamping is ideal for high-volume production with relatively simple shapes, offering cost-effective and fast cycle times. Deep drawing suits intricate, high-depth parts requiring excellent strength and uniformity, ensuring your project achieves precise tolerances and optimal structural integrity.

Sheet Metal Stamping vs Deep Drawing Infographic

libmatt.com

libmatt.com