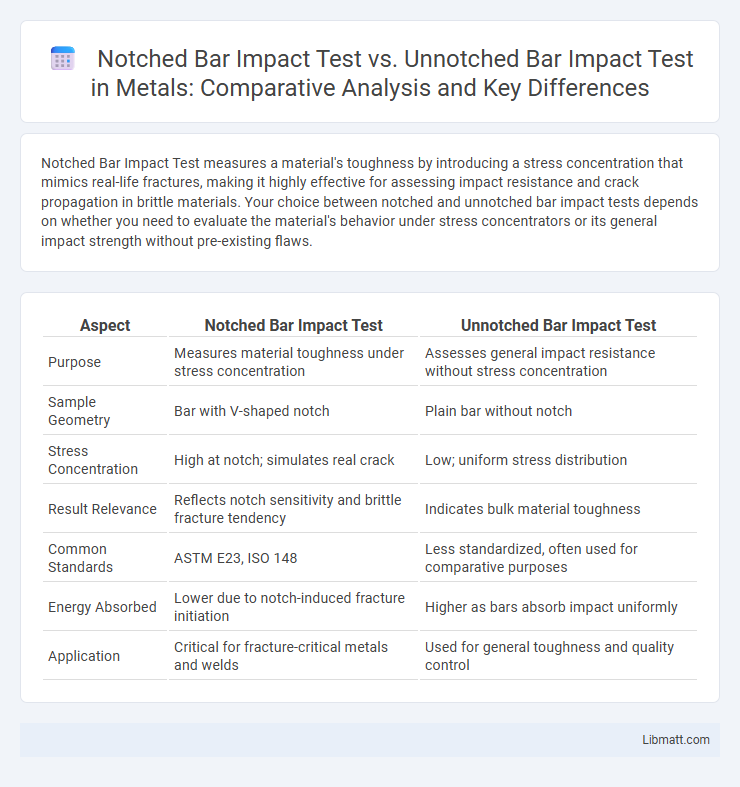

Notched Bar Impact Test measures a material's toughness by introducing a stress concentration that mimics real-life fractures, making it highly effective for assessing impact resistance and crack propagation in brittle materials. Your choice between notched and unnotched bar impact tests depends on whether you need to evaluate the material's behavior under stress concentrators or its general impact strength without pre-existing flaws.

Table of Comparison

| Aspect | Notched Bar Impact Test | Unnotched Bar Impact Test |

|---|---|---|

| Purpose | Measures material toughness under stress concentration | Assesses general impact resistance without stress concentration |

| Sample Geometry | Bar with V-shaped notch | Plain bar without notch |

| Stress Concentration | High at notch; simulates real crack | Low; uniform stress distribution |

| Result Relevance | Reflects notch sensitivity and brittle fracture tendency | Indicates bulk material toughness |

| Common Standards | ASTM E23, ISO 148 | Less standardized, often used for comparative purposes |

| Energy Absorbed | Lower due to notch-induced fracture initiation | Higher as bars absorb impact uniformly |

| Application | Critical for fracture-critical metals and welds | Used for general toughness and quality control |

Introduction to Impact Testing

Impact testing measures a material's ability to absorb energy during a high-velocity impact, revealing toughness and resistance to sudden loads. Notched bar impact tests, such as the Charpy test, introduce a notch to concentrate stress and promote fracture, simulating real-world flaws and weaknesses. Unnotched bar impact tests evaluate the material's inherent toughness without stress concentrators, providing insight into its intrinsic resistance to impact forces.

Overview of Notched Bar Impact Test

The Notched Bar Impact Test evaluates a material's toughness by measuring the energy absorbed during fracture when a notched specimen is struck by a pendulum. This test simulates real-world stress concentrations by introducing a notch, which promotes crack initiation and growth, providing critical data on material behavior under impact conditions. Your material's performance in this test helps predict its resistance to sudden impacts and potential failure in structural applications.

Overview of Unnotched Bar Impact Test

The Unnotched Bar Impact Test evaluates a material's toughness by measuring its ability to absorb energy during fracture without a notch, reflecting its intrinsic resistance to impact. This test provides valuable data on the natural ductility and brittleness of a material, helping to predict performance under sudden loading conditions. Understanding your material's behavior through this test can guide effective design choices in applications where smooth surface integrity is critical.

Purpose and Applications of Notched Bar Test

The Notched Bar Impact Test is designed to measure a material's toughness and its ability to absorb energy during fracture, particularly under sudden impact. This test is widely applied in evaluating the brittleness and notch sensitivity of metals, plastics, and composites used in structural and safety-critical components. You can rely on this test to predict material performance in real-world conditions where stress concentrations occur, such as in automotive, aerospace, and construction industries.

Purpose and Applications of Unnotched Bar Test

The Unnotched Bar Impact Test primarily measures the overall toughness and energy absorption capacity of a material without the stress concentration effects seen in notched specimens, providing insight into general material behavior under impact. It is widely applied in quality control and comparative assessments of materials where notch sensitivity is not critical, such as in metals with high ductility or homogeneity. This test is essential for evaluating materials used in industries like automotive manufacturing and structural engineering, where resistance to sudden forces without localized fracture is crucial.

Key Differences Between Notched and Unnotched Tests

Notched bar impact tests feature a predefined notch that concentrates stress, simulating real-world crack initiation and providing reliable data on a material's toughness and fracture resistance. Unnotched bar impact tests lack this stress concentrator, resulting in higher absorbed energy measurements that emphasize the material's overall ductility and energy absorption capacity. The key difference lies in the notched test's ability to evaluate notch sensitivity and fracture mechanics, while unnotched tests assess general impact strength without focusing on crack propagation behavior.

Material Behavior Insights from Notched vs Unnotched

Notched bar impact tests concentrate stress at the notch, revealing a material's fracture toughness and susceptibility to brittle failure under sudden impacts, which is critical for assessing notch sensitivity in metals and polymers. Unnotched bar impact tests provide a measure of the material's overall energy absorption capability without stress concentration, highlighting general toughness and ductility. Comparing results from both tests offers insights into how defects or stress concentrators affect material behavior, essential for predicting service performance and structural integrity.

Testing Standards and Procedures

Notched bar impact tests, such as the Charpy and Izod tests, follow standardized procedures defined by ASTM E23 and ISO 148, where a V-shaped notch is machined to concentrate stress and measure material toughness under impact. Unnotched bar impact tests, less common and lacking widely accepted standards, generally assess the material's energy absorption without the stress concentration effect, often requiring customized protocols. The notched test's standardized setup ensures consistent impact velocity, specimen dimensions, and notch geometry, providing reproducible results critical for material comparison and quality control.

Interpreting Results: Notched vs Unnotched

The notched bar impact test measures material toughness by concentrating stress at the notch, providing insights into fracture behavior under sudden impact and highlighting brittleness or ductility. In contrast, the unnotched bar impact test evaluates the material's overall energy absorption without stress concentration, reflecting its general toughness. Your interpretation of results should consider that notched tests emphasize crack initiation resistance, while unnotched tests indicate bulk material resilience.

Conclusion: Choosing the Right Impact Test

Selecting the appropriate impact test depends on the material's intended application and the specific properties you need to evaluate. The Notched Bar Impact Test highlights a material's notch sensitivity and fracture toughness under sudden impact, making it ideal for assessing brittle fracture behavior. In contrast, the Unnotched Bar Impact Test measures the material's general impact resistance without stress concentration, providing insight into its overall toughness in less severe conditions.

Notched Bar Impact Test vs Unnotched Bar Impact Test Infographic

libmatt.com

libmatt.com