Spin forming uses gradual metal deformation by spinning a workpiece against a roller to create hollow shapes, ideal for custom, low-volume production; deep drawing involves pressing a sheet metal blank into a die cavity with a punch to form complex, high-volume parts with precise dimensions. Your choice depends on factors like production volume, part complexity, and material thickness.

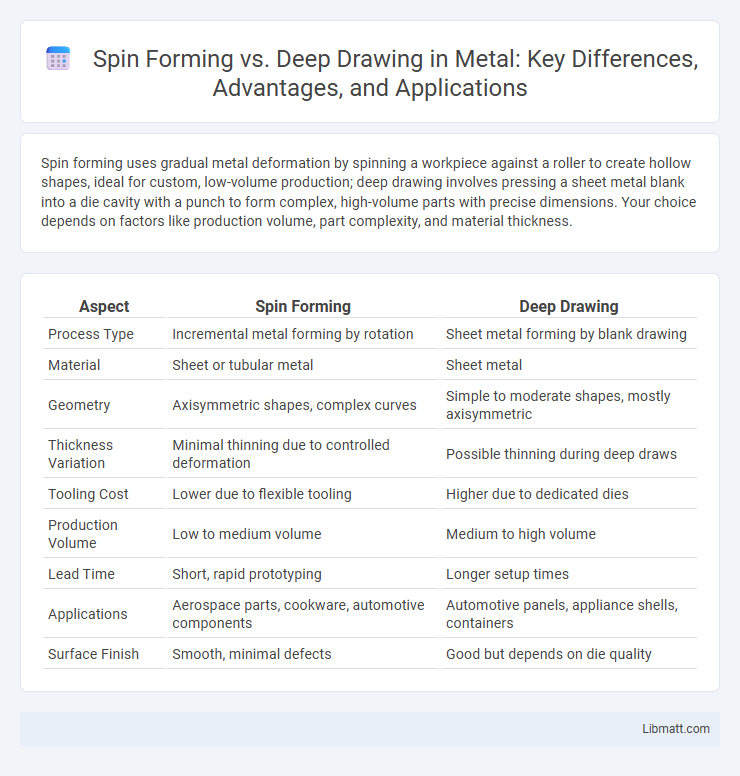

Table of Comparison

| Aspect | Spin Forming | Deep Drawing |

|---|---|---|

| Process Type | Incremental metal forming by rotation | Sheet metal forming by blank drawing |

| Material | Sheet or tubular metal | Sheet metal |

| Geometry | Axisymmetric shapes, complex curves | Simple to moderate shapes, mostly axisymmetric |

| Thickness Variation | Minimal thinning due to controlled deformation | Possible thinning during deep draws |

| Tooling Cost | Lower due to flexible tooling | Higher due to dedicated dies |

| Production Volume | Low to medium volume | Medium to high volume |

| Lead Time | Short, rapid prototyping | Longer setup times |

| Applications | Aerospace parts, cookware, automotive components | Automotive panels, appliance shells, containers |

| Surface Finish | Smooth, minimal defects | Good but depends on die quality |

Introduction to Spin Forming and Deep Drawing

Spin forming uses rotational force to shape metal over a mandrel, ideal for producing axisymmetric parts with smooth surfaces and variable thickness. Deep drawing involves stretching a metal sheet into a die cavity, creating complex shapes with high precision and consistent wall thickness. Understanding these processes helps you select the best method for manufacturing components like automotive panels or aerospace parts.

Overview of Spin Forming Process

Spin forming is a metal shaping technique that uses a rotating metal blank clamped against a form or mandrel while a roller tool applies localized pressure to gradually shape the material. This process is ideal for creating symmetrical, hollow components like cones, cylinders, and domes with minimal waste and high material efficiency. You benefit from spin forming's flexibility and precision, especially when manufacturing medium to large-sized parts with complex curves not easily achieved via deep drawing.

Fundamentals of Deep Drawing Technique

Deep drawing is a metal forming process where a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch, creating hollow shapes with high precision. The fundamental technique involves controlling blank holder force, punch speed, and lubrication to prevent defects like wrinkling or tearing. You benefit from understanding these parameters to enhance product quality and consistency in manufacturing deep-drawn components.

Key Differences Between Spin Forming and Deep Drawing

Spin forming uses a rotating mandrel and rollers to shape metal sheets into axially symmetric parts, offering greater flexibility for complex curves and varying thicknesses. Deep drawing involves pulling a metal blank into a die cavity to create uniform cup-shaped parts with sharp edges, typically suitable for high-volume production of consistent geometries. Understanding key differences like form complexity, tooling costs, and production speed helps you choose the appropriate metal forming process for your manufacturing needs.

Material Suitability for Each Process

Spin forming excels with ductile metals like aluminum, copper, and mild steel, allowing for gradual deformation without compromising material integrity. Deep drawing suits materials with high tensile strength and good formability such as stainless steel and low-carbon steel, enabling complex shapes to be drawn from flat sheets. Your choice depends on the material's thickness, ductility, and desired final geometry for optimal manufacturing results.

Advantages of Spin Forming

Spin forming offers precise control over metal shaping, enabling the production of complex, large-diameter parts with uniform thickness and minimal material waste. Unlike deep drawing, spin forming allows for greater flexibility in adjusting wall thickness during the process, resulting in stronger, lightweight components for industries like aerospace and automotive. This technique reduces tooling costs and setup time, making it cost-effective for both prototyping and low- to medium-volume production runs.

Benefits of Deep Drawing

Deep drawing offers precise control over complex shapes with excellent surface finish and dimensional accuracy, making it ideal for producing intricate metal components. It provides high material utilization and reduced waste compared to other forming methods, enhancing cost efficiency in large-scale manufacturing. The process also supports high production rates with consistent repeatability, ensuring reliable quality for automotive, aerospace, and appliance industries.

Typical Applications and Industries

Spin forming excels in producing large, symmetrical metal parts with smooth finishes, commonly used in aerospace fuel tanks, satellite components, and cookware manufacturing. Deep drawing is ideal for creating complex, high-volume parts such as automotive panels, beverage cans, and household appliances due to its precision and repeatability. Your choice between these processes depends on the required part geometry, production volume, and application-specific industry standards.

Cost Considerations and Production Volume

Spin forming typically offers lower initial tooling costs compared to deep drawing, making it more cost-effective for low to medium production volumes. Deep drawing involves higher upfront expenses due to tooling complexity but becomes more economical as production volume increases because of faster cycle times and higher repeatability. Your choice depends on balancing these cost factors with the anticipated quantity, where spin forming suits smaller batches and deep drawing excels in large-scale manufacturing.

Choosing the Right Process: Factors to Consider

Choosing between spin forming and deep drawing depends primarily on the material type, part complexity, and production volume. Spin forming excels in producing symmetrical, cylindrical parts with minimal tooling costs, ideal for low to medium volumes and ductile metals like aluminum and steel. Deep drawing is better suited for high-volume production of complex shapes requiring precise details and thicker materials, such as stainless steel and copper alloys.

spin forming vs deep drawing Infographic

libmatt.com

libmatt.com