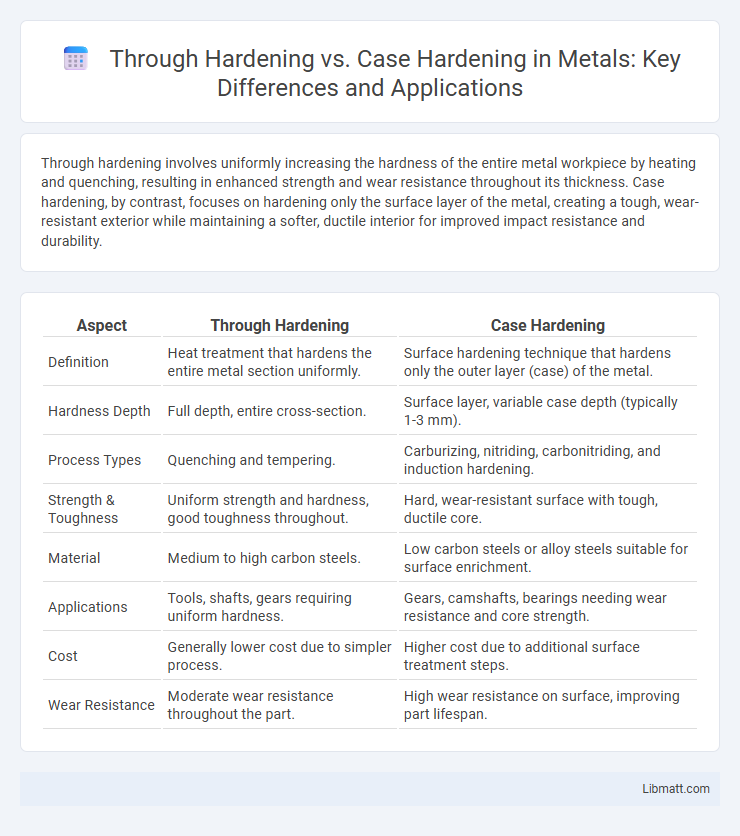

Through hardening involves uniformly increasing the hardness of the entire metal workpiece by heating and quenching, resulting in enhanced strength and wear resistance throughout its thickness. Case hardening, by contrast, focuses on hardening only the surface layer of the metal, creating a tough, wear-resistant exterior while maintaining a softer, ductile interior for improved impact resistance and durability.

Table of Comparison

| Aspect | Through Hardening | Case Hardening |

|---|---|---|

| Definition | Heat treatment that hardens the entire metal section uniformly. | Surface hardening technique that hardens only the outer layer (case) of the metal. |

| Hardness Depth | Full depth, entire cross-section. | Surface layer, variable case depth (typically 1-3 mm). |

| Process Types | Quenching and tempering. | Carburizing, nitriding, carbonitriding, and induction hardening. |

| Strength & Toughness | Uniform strength and hardness, good toughness throughout. | Hard, wear-resistant surface with tough, ductile core. |

| Material | Medium to high carbon steels. | Low carbon steels or alloy steels suitable for surface enrichment. |

| Applications | Tools, shafts, gears requiring uniform hardness. | Gears, camshafts, bearings needing wear resistance and core strength. |

| Cost | Generally lower cost due to simpler process. | Higher cost due to additional surface treatment steps. |

| Wear Resistance | Moderate wear resistance throughout the part. | High wear resistance on surface, improving part lifespan. |

Introduction to Hardening Processes

Through hardening transforms the entire metal workpiece by heating and quenching, resulting in uniform hardness and improved strength throughout the material. Case hardening selectively hardens the surface layer through carburizing or nitriding, creating a tough outer shell while maintaining a ductile core. Both methods enhance wear resistance and fatigue strength but differ in depth and application depending on mechanical requirements.

What is Through Hardening?

Through hardening is a heat treatment process that hardens the entire cross-section of a metal component, ensuring uniform hardness from the surface to the core. This method involves heating the metal to a specific temperature followed by rapid quenching to achieve maximum penetration of hardness, making it ideal for parts subjected to high stress throughout. It contrasts with case hardening, which only hardens the surface layer while maintaining a softer, ductile core.

What is Case Hardening?

Case hardening is a heat treatment process that enhances the surface hardness of metal parts while maintaining a softer, ductile core, improving wear resistance without compromising toughness. It typically involves introducing carbon or nitrogen to the surface layer through techniques such as carburizing or nitriding, creating a hard, wear-resistant outer shell. Your components gain increased durability and fatigue strength, making case hardening ideal for gears, camshafts, and other high-stress applications.

Key Differences: Through Hardening vs Case Hardening

Through hardening involves heating and quenching the entire metal piece to achieve uniform hardness throughout, enhancing strength and wear resistance. Case hardening, in contrast, hardens only the surface layer by diffusing carbon or nitrogen into the metal, preserving a tough, ductile core for improved fatigue resistance. Your choice depends on whether you require full-depth hardness or a hard, wear-resistant surface with a softer interior.

Applications of Through Hardening

Through hardening is widely used in applications requiring uniform hardness and strength throughout the entire component, such as gears, shafts, and crankshafts in automotive and heavy machinery industries. This process enhances wear resistance and fatigue strength, making it ideal for parts subjected to high stress and impact loads. Unlike case hardening, which only hardens the surface layer, through hardening ensures deep core hardness for improved durability in critical structural components.

Applications of Case Hardening

Case hardening is widely applied in manufacturing gears, camshafts, and crankshafts, where a tough interior and a wear-resistant surface are essential for durability and performance. Your machine components benefit from increased surface hardness while maintaining a ductile core to absorb shocks and resist fatigue. This process is favored in automotive and heavy machinery industries due to its efficiency in enhancing part lifespan without compromising core toughness.

Material Suitability for Each Method

Through hardening is ideal for low-carbon steel and alloys that require uniform hardness and strength throughout the entire cross-section. Case hardening suits low-carbon steels needing a hard, wear-resistant surface while retaining a tough, ductile core, such as in gears and camshafts. Your choice depends on whether uniform hardness or surface hardness with a ductile core is essential for the application.

Advantages and Disadvantages Comparison

Through hardening offers uniform hardness throughout the entire metal, enhancing wear resistance and structural strength but may lead to brittleness and reduced toughness. Case hardening provides a hard, wear-resistant surface while maintaining a softer, ductile core, improving impact resistance but limiting hardness depth to the surface layer. Through hardening suits components requiring full-section strength, whereas case hardening is ideal for parts needing surface durability with internal flexibility.

Cost Considerations in Hardening Techniques

Through hardening generally incurs higher costs due to the need for prolonged heating and precise temperature control to achieve uniform hardness throughout the entire material. Case hardening, by contrast, offers cost efficiency by hardening only the surface layer, reducing energy consumption and processing time while maintaining a tough core. Selecting between these techniques depends on balancing budget constraints with performance requirements for specific applications.

Choosing the Right Hardening Method for Your Needs

Through hardening provides uniform hardness throughout the entire metal piece, making it ideal for components requiring high strength and wear resistance internally and externally. Case hardening strengthens only the outer surface, preserving the core's toughness and ductility, which suits parts subjected to surface abrasion while needing a tough interior. Your choice between through hardening and case hardening depends on whether you prioritize comprehensive hardness or a durable, impact-resistant core with a hardened exterior.

through hardening vs case hardening Infographic

libmatt.com

libmatt.com