Zinc plating provides excellent corrosion resistance and is commonly used for automotive and industrial parts, while tin plating offers superior solderability and electrical conductivity, ideal for electronic components. Choosing the right plating depends on Your specific application requirements, including environmental exposure and conductivity needs.

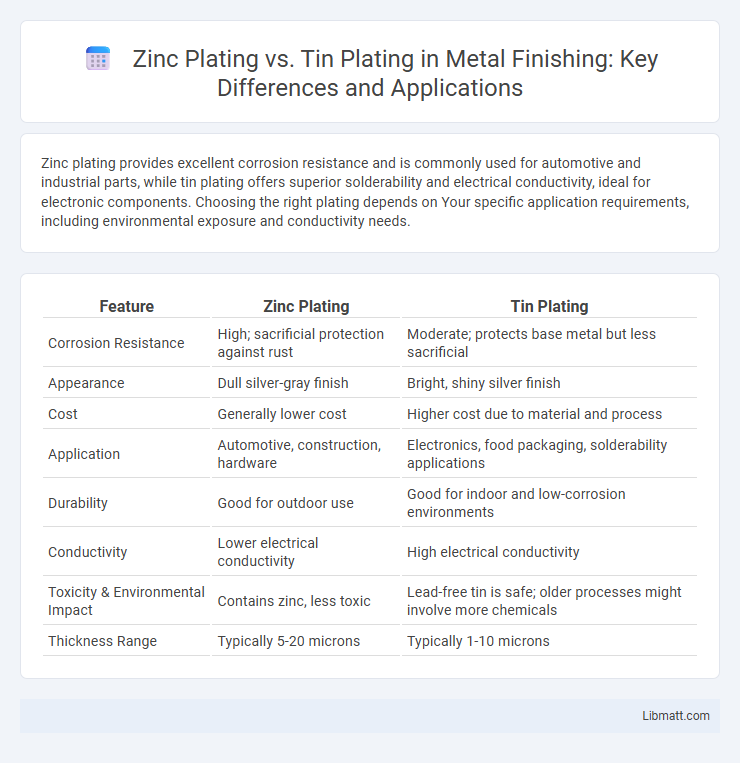

Table of Comparison

| Feature | Zinc Plating | Tin Plating |

|---|---|---|

| Corrosion Resistance | High; sacrificial protection against rust | Moderate; protects base metal but less sacrificial |

| Appearance | Dull silver-gray finish | Bright, shiny silver finish |

| Cost | Generally lower cost | Higher cost due to material and process |

| Application | Automotive, construction, hardware | Electronics, food packaging, solderability applications |

| Durability | Good for outdoor use | Good for indoor and low-corrosion environments |

| Conductivity | Lower electrical conductivity | High electrical conductivity |

| Toxicity & Environmental Impact | Contains zinc, less toxic | Lead-free tin is safe; older processes might involve more chemicals |

| Thickness Range | Typically 5-20 microns | Typically 1-10 microns |

Introduction to Metal Plating: Zinc vs Tin

Zinc plating offers superior corrosion resistance by forming a protective barrier that prevents rust, making it ideal for automotive and hardware applications. Tin plating provides excellent solderability and electrical conductivity, commonly used in electronics and food packaging to enhance surface durability. Your choice between zinc and tin plating depends on whether corrosion protection or electrical performance is the priority for your metal components.

Chemical Properties of Zinc and Tin Plating

Zinc plating exhibits excellent corrosion resistance due to its ability to form a stable, protective zinc oxide layer, which prevents oxidation of the underlying metal. Tin plating offers superior electrical conductivity and solderability, making it ideal for electronic components, but it is less resistant to corrosion compared to zinc. Both plating types provide distinct chemical properties where zinc acts as a sacrificial anode, while tin primarily serves as a barrier coating.

Corrosion Resistance Comparison

Zinc plating offers superior corrosion resistance by forming a protective barrier that prevents rust and extends the lifespan of metal components, especially in outdoor or humid environments. Tin plating provides excellent corrosion resistance against acids and solderability, making it ideal for electrical and electronic applications where long-term conductivity is crucial. Your choice between zinc plating and tin plating should consider the specific environmental exposure and performance requirements for optimal protection.

Application Areas: Zinc vs Tin Plating

Zinc plating is extensively applied in automotive, construction, and hardware industries due to its excellent corrosion resistance and cost-effectiveness, making it ideal for steel and iron components exposed to harsh environments. Tin plating is predominantly used in electronics, food packaging, and electrical connectors because of its superior solderability, non-toxic nature, and resistance to corrosion in cold and wet environments. Both plating methods serve critical functions, with zinc favored for durability and tin chosen for electrical conductivity and safety in consumer products.

Cost Analysis: Zinc Plating vs Tin Plating

Zinc plating generally offers a lower cost compared to tin plating due to its widespread availability and simpler application process. Tin plating, while more expensive, provides superior corrosion resistance and solderability, which may justify the higher investment for specialized uses. Evaluating your project's requirements and budget will help determine the cost-effectiveness between zinc plating and tin plating methods.

Plating Process Differences

Zinc plating involves electroplating a thin layer of zinc onto metal surfaces to provide corrosion resistance through sacrificial protection, while tin plating deposits a layer of tin primarily for enhanced solderability and corrosion resistance. Zinc plating typically requires surface cleaning, rinsing, and immersion in a zinc electrolyte bath with precise current control, whereas tin plating often uses a tin electrolyte bath and may involve additional brighteners or additives to ensure smooth, uniform coverage. The difference in plating baths, chemical composition, and final application purpose distinguishes the zinc plating process from tin plating in industrial manufacturing.

Environmental and Safety Considerations

Zinc plating offers corrosion resistance with a lower environmental impact due to its non-toxic nature and ease of recycling, while tin plating involves concerns about tin whiskers, which can cause electrical short circuits and pose safety risks in electronics. Zinc plating processes typically emit fewer hazardous substances compared to tin plating, reducing workplace health risks and environmental contamination. Your choice between the two should consider these factors, especially if minimizing ecological footprint and ensuring long-term safety are priorities.

Adhesion and Surface Finish Quality

Zinc plating offers superior adhesion due to its ability to form a strong metallurgical bond with the base metal, resulting in robust corrosion resistance and durability. Tin plating provides a smoother, more reflective surface finish, ideal for improving electrical conductivity and solderability, especially in electronics. Your choice between zinc and tin plating depends on whether adhesion strength or surface finish quality is the top priority for your application.

Typical Lifespan and Maintenance Needs

Zinc plating typically offers a lifespan of 6 to 12 months in outdoor environments due to its moderate corrosion resistance, requiring periodic maintenance such as cleaning and reapplication of protective coatings to prolong durability. Tin plating provides excellent corrosion resistance and a typical lifespan exceeding 10 years, especially in indoor or low-humidity conditions, with minimal maintenance needed due to its inherent tin oxide protective layer. Both plating types demand specific environment considerations for optimal performance, where zinc is preferred for sacrificial protection and tin is favored for solderability and precision electronic components.

Choosing the Right Plating for Your Application

Zinc plating offers excellent corrosion resistance and is ideal for automotive and construction applications where durability against rust is crucial. Tin plating provides superior solderability and electrical conductivity, making it suitable for electronic components and connectors. Evaluating your specific environmental conditions and performance requirements will help you choose the right plating for your application.

Zinc plating vs tin plating Infographic

libmatt.com

libmatt.com