Phosphating provides a durable, corrosion-resistant coating by forming a crystalline phosphate layer, while chromating offers superior corrosion protection with a thin, chemical conversion coating often used as a primer. Your choice depends on the specific application requirements, balancing environmental considerations and performance needs.

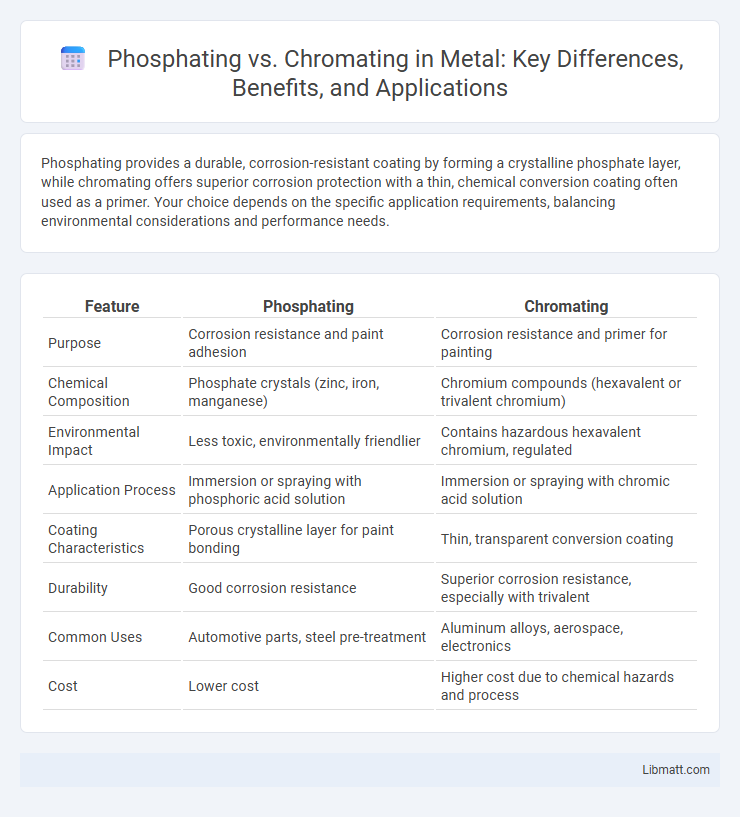

Table of Comparison

| Feature | Phosphating | Chromating |

|---|---|---|

| Purpose | Corrosion resistance and paint adhesion | Corrosion resistance and primer for painting |

| Chemical Composition | Phosphate crystals (zinc, iron, manganese) | Chromium compounds (hexavalent or trivalent chromium) |

| Environmental Impact | Less toxic, environmentally friendlier | Contains hazardous hexavalent chromium, regulated |

| Application Process | Immersion or spraying with phosphoric acid solution | Immersion or spraying with chromic acid solution |

| Coating Characteristics | Porous crystalline layer for paint bonding | Thin, transparent conversion coating |

| Durability | Good corrosion resistance | Superior corrosion resistance, especially with trivalent |

| Common Uses | Automotive parts, steel pre-treatment | Aluminum alloys, aerospace, electronics |

| Cost | Lower cost | Higher cost due to chemical hazards and process |

Introduction to Phosphating and Chromating

Phosphating involves applying a phosphate coating to metal surfaces to enhance corrosion resistance, improve paint adhesion, and provide lubrication during forming processes. Chromating creates a thin, protective layer of chromium compounds on metals, particularly aluminum and zinc, significantly boosting corrosion resistance and improving surface conductivity. Both processes are essential in surface treatment industries, with phosphating widely used for steel and chromating favored for non-ferrous metals.

Chemical Processes Explained

Phosphating involves applying a conversion coating of phosphate crystals on a metal surface through immersion in a phosphoric acid solution, which enhances corrosion resistance and paint adhesion. Chromating uses a chromate conversion coating formed by treating metals with a hexavalent chromium solution, providing superior corrosion protection and electrical conductivity. Your choice between these chemical processes depends on the required corrosion resistance, environmental considerations, and end-use application.

Surface Preparation Methods

Phosphating and chromating are essential surface preparation methods that enhance metal corrosion resistance and paint adhesion. Phosphating creates a crystalline phosphate coating primarily on steel, improving lubrication and reducing friction during subsequent processing. Chromating, often used on aluminum and zinc alloys, forms a thin, transparent oxide layer that offers superior corrosion protection and acts as an excellent base for paint or sealants.

Key Differences Between Phosphating and Chromating

Phosphating forms a crystalline phosphate layer providing corrosion resistance and paint adhesion, mainly using zinc, iron, or manganese phosphates, while chromating creates a thin, protective chromium oxide film that enhances corrosion protection and electrical conductivity. You should choose phosphating for improved paint adherence in automotive and appliance industries, whereas chromating is preferred in aluminum finishing and electronics due to its superior corrosion resistance. The environmental impact also differs, as chromating involves hexavalent chromium compounds, which are more toxic compared to the typically less hazardous phosphate coatings.

Advantages of Phosphating

Phosphating offers superior corrosion resistance and enhanced paint adhesion compared to chromating, resulting in more durable surface protection for metals. It provides an eco-friendlier alternative by using fewer hazardous chemicals and generating less toxic waste. This process also improves lubrication retention during metal forming, reducing wear and increasing manufacturing efficiency.

Advantages of Chromating

Chromating offers superior corrosion resistance and excellent adhesion for subsequent coatings, making it ideal for enhancing the durability of metal surfaces. This process creates a thin, transparent conversion coating that improves electrical conductivity and reduces friction, which can extend the lifespan of treated components. You benefit from chromating when seeking a more environmentally friendly alternative to traditional phosphating with lower waste and reduced hazardous byproducts.

Applications in Industry

Phosphating is widely used in automotive and appliance manufacturing to enhance corrosion resistance and improve paint adhesion on steel surfaces. Chromating typically finds applications in aerospace and electronics industries due to its superior corrosion protection and conductivity properties. Your choice between these coatings depends on the desired balance between environmental regulations and performance requirements.

Environmental Impact and Safety

Phosphating involves the application of phosphate coatings, which generate less toxic waste compared to chromating processes that use hexavalent chromium, a known carcinogen with significant environmental and health hazards. The disposal and treatment of chromium-containing effluents require stringent regulations to mitigate soil and water contamination risks, whereas phosphating by-products are more biodegradable and environmentally manageable. Safety protocols for chromating must address exposure to hazardous chromium compounds, while phosphating poses lower chemical risks to workers, making it a more sustainable option in industrial surface treatment.

Cost Comparison and Efficiency

Phosphating generally offers lower initial costs and simpler application processes compared to chromating, making it a more cost-effective choice for large-scale operations. Chromating provides superior corrosion resistance and longer-lasting protection, enhancing overall efficiency despite higher material and processing expenses. Evaluating your specific application needs and budget will help determine the optimal balance between upfront costs and long-term performance benefits.

Selecting the Right Surface Treatment

Selecting the right surface treatment between phosphating and chromating depends on the desired corrosion resistance, paint adhesion, and environmental impact requirements. Phosphating offers excellent base layer protection for paint and is widely used in automotive and appliance industries due to its cost-effectiveness and biodegradability. Chromating provides superior corrosion resistance and electrical conductivity but involves toxic hexavalent chromium, making it suitable mainly for aerospace and military applications with strict regulatory controls.

Phosphating vs Chromating Infographic

libmatt.com

libmatt.com