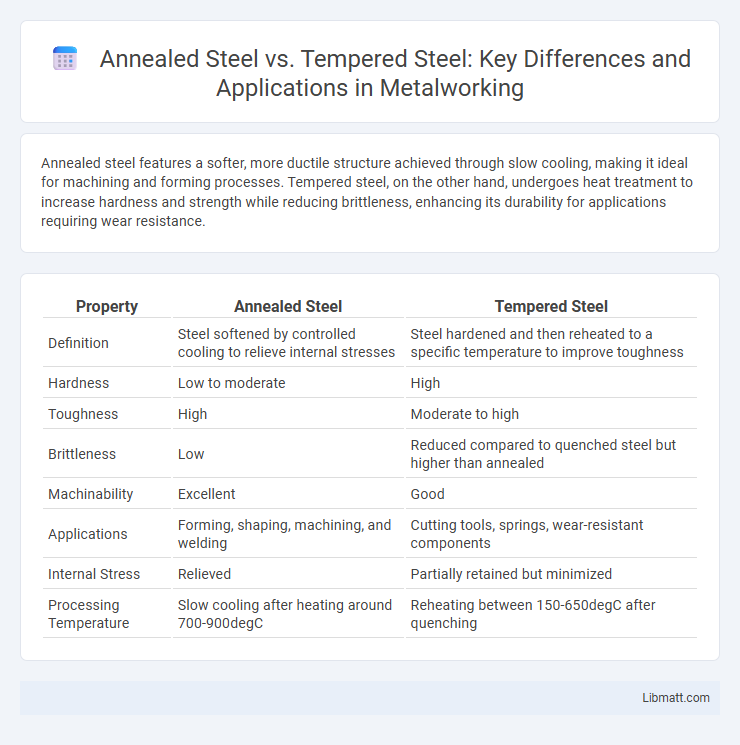

Annealed steel features a softer, more ductile structure achieved through slow cooling, making it ideal for machining and forming processes. Tempered steel, on the other hand, undergoes heat treatment to increase hardness and strength while reducing brittleness, enhancing its durability for applications requiring wear resistance.

Table of Comparison

| Property | Annealed Steel | Tempered Steel |

|---|---|---|

| Definition | Steel softened by controlled cooling to relieve internal stresses | Steel hardened and then reheated to a specific temperature to improve toughness |

| Hardness | Low to moderate | High |

| Toughness | High | Moderate to high |

| Brittleness | Low | Reduced compared to quenched steel but higher than annealed |

| Machinability | Excellent | Good |

| Applications | Forming, shaping, machining, and welding | Cutting tools, springs, wear-resistant components |

| Internal Stress | Relieved | Partially retained but minimized |

| Processing Temperature | Slow cooling after heating around 700-900degC | Reheating between 150-650degC after quenching |

Introduction to Annealed and Tempered Steel

Annealed steel undergoes a heat treatment process that softens the metal, enhancing its ductility and reducing hardness, which improves machinability and formability. Tempered steel is produced by reheating quenched steel to a specific temperature below its critical point, optimizing the balance between hardness and toughness to increase mechanical strength and resistance to wear. The contrasting thermal treatments define their distinct mechanical properties, making annealed steel ideal for shaping and tempered steel suited for structural applications.

What is Annealed Steel?

Annealed steel is a type of metal that has undergone a controlled heating and slow cooling process to reduce hardness and increase ductility, making it easier to work with in manufacturing. This heat treatment refines the grain structure and relieves internal stresses, enhancing machinability and improving formability. Commonly used in applications requiring extensive shaping or welding, annealed steel offers improved toughness and uniformity compared to untreated steel.

What is Tempered Steel?

Tempered steel is a type of heat-treated steel that has undergone a controlled heating and cooling process to increase its toughness and reduce brittleness. This treatment enhances the steel's mechanical properties, such as hardness and strength, making it ideal for tools, knives, and structural components subjected to high stress. Understanding tempered steel helps you select materials with improved durability and resistance to impact in your projects.

Manufacturing Processes: Annealing vs Tempering

Annealed steel undergoes a heat treatment process where it is heated to a specific temperature and then slowly cooled to soften the metal, improving its ductility and reducing hardness. Tempering involves reheating quenched steel to a lower temperature followed by controlled cooling, enhancing toughness and relieving internal stresses while maintaining increased strength. These distinct manufacturing processes result in annealed steel being more malleable for machining, whereas tempered steel offers a balanced combination of hardness and resilience for structural applications.

Microstructural Differences

Annealed steel exhibits a coarse pearlite microstructure with increased ductility due to slow cooling, resulting in softer and more malleable properties. Tempered steel contains tempered martensite characterized by fine carbides precipitated within a ferritic matrix, enhancing strength and toughness after quenching and reheating. These microstructural differences directly influence mechanical behavior, with annealed steel offering improved formability and tempered steel providing superior hardness and wear resistance.

Mechanical Properties Comparison

Annealed steel exhibits lower hardness and tensile strength but offers superior ductility and toughness, making it ideal for processes requiring extensive shaping or forming. Tempered steel, treated through controlled heating and cooling, achieves enhanced hardness, strength, and wear resistance while maintaining moderate toughness, optimizing it for applications demanding durability and impact resistance. The mechanical properties of annealed steel prioritize flexibility and machinability, whereas tempered steel emphasizes improved strength-to-weight ratio and fatigue resistance.

Applications of Annealed Steel

Annealed steel is widely used in applications requiring improved ductility and reduced hardness, such as in automotive components, machinery parts, and metal forming processes. This material's enhanced machinability and ability to absorb impact make it ideal for manufacturing pipelines, structural parts, and tools that undergo significant shaping or welding. You will find annealed steel preferred in industries where flexibility and ease of fabrication are essential for performance and durability.

Applications of Tempered Steel

Tempered steel is widely used in applications requiring high strength, toughness, and resistance to wear, such as automotive components, cutting tools, and structural parts. Its enhanced mechanical properties make it ideal for springs, knives, and heavy machinery where durability under stress is critical. You can rely on tempered steel for critical performance in demanding environments due to its optimized balance of hardness and flexibility.

Cost Considerations and Availability

Annealed steel typically incurs lower costs due to its simpler heat treatment process, making it more affordable for large-scale manufacturing and general applications. Tempered steel demands higher production expenses because of precise reheating and cooling cycles that enhance strength and toughness, which may limit its availability in certain markets. Your choice depends on balancing budget constraints with performance needs, as annealed steel offers cost-efficiency, while tempered steel provides superior durability but at a premium price.

Choosing Between Annealed and Tempered Steel

Choosing between annealed and tempered steel depends on the specific requirements of your project, as annealed steel offers enhanced ductility and ease of machining due to its softened state, while tempered steel provides superior strength and toughness by undergoing heat treatment after quenching. Annealed steel is ideal for applications needing forming and bending, whereas tempered steel suits environments demanding high resistance to impact and wear. Understanding these differences ensures you select the steel type that best aligns with your mechanical and durability needs.

annealed steel vs tempered steel Infographic

libmatt.com

libmatt.com