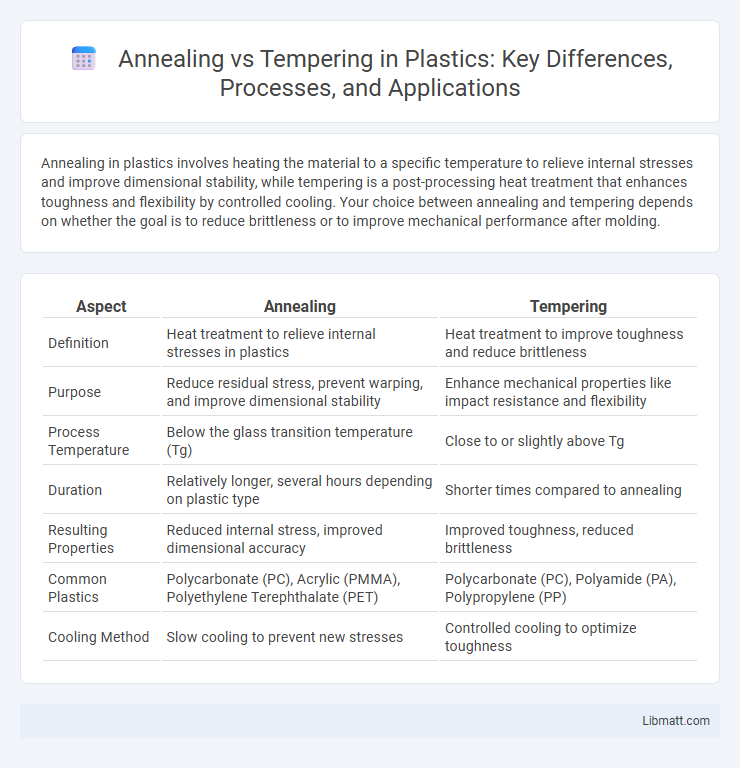

Annealing in plastics involves heating the material to a specific temperature to relieve internal stresses and improve dimensional stability, while tempering is a post-processing heat treatment that enhances toughness and flexibility by controlled cooling. Your choice between annealing and tempering depends on whether the goal is to reduce brittleness or to improve mechanical performance after molding.

Table of Comparison

| Aspect | Annealing | Tempering |

|---|---|---|

| Definition | Heat treatment to relieve internal stresses in plastics | Heat treatment to improve toughness and reduce brittleness |

| Purpose | Reduce residual stress, prevent warping, and improve dimensional stability | Enhance mechanical properties like impact resistance and flexibility |

| Process Temperature | Below the glass transition temperature (Tg) | Close to or slightly above Tg |

| Duration | Relatively longer, several hours depending on plastic type | Shorter times compared to annealing |

| Resulting Properties | Reduced internal stress, improved dimensional accuracy | Improved toughness, reduced brittleness |

| Common Plastics | Polycarbonate (PC), Acrylic (PMMA), Polyethylene Terephthalate (PET) | Polycarbonate (PC), Polyamide (PA), Polypropylene (PP) |

| Cooling Method | Slow cooling to prevent new stresses | Controlled cooling to optimize toughness |

Introduction to Annealing and Tempering in Plastics

Annealing in plastics involves heating the material to a specific temperature below its melting point to relieve internal stresses and improve dimensional stability. Tempering, on the other hand, adjusts the mechanical properties by controlled reheating, often enhancing toughness and reducing brittleness. Both processes are critical in optimizing the performance and durability of polymers used in engineering applications.

Definition of Annealing in Plastics

Annealing in plastics refers to a controlled heating process where the material is heated to a specific temperature below its melting point and then slowly cooled to relieve internal stresses and improve dimensional stability. This process enhances the polymer's mechanical properties by reducing brittleness and minimizing warpage or shrinkage during subsequent processing. Annealing is essential for maintaining the structural integrity of thermoplastics and preventing deformation under thermal or mechanical loads.

Definition of Tempering in Plastics

Tempering in plastics refers to a controlled heat treatment process aimed at improving material toughness and reducing internal stresses without altering the polymer's crystalline structure. It typically involves heating the plastic to a specific temperature below its melting point and then cooling it gradually to enhance dimensional stability and mechanical performance. Understanding tempering helps you optimize plastic parts for better durability and resistance to impact or deformation.

Key Differences Between Annealing and Tempering

Annealing in plastics involves heating the material to a specific temperature below its melting point and then slowly cooling to relieve internal stresses and improve dimensional stability, whereas tempering typically refers to controlled reheating to adjust mechanical properties after processes like quenching. Annealing primarily targets reducing brittleness and enhancing ductility by allowing polymer chains to reorganize, while tempering modifies strength and toughness by balancing hardness and flexibility. The key difference lies in annealing's stress relief and structural relaxation focus compared to tempering's goal of fine-tuning mechanical performance through partial reheating.

Purpose and Benefits of Annealing Plastics

Annealing plastics involves heating them to a specific temperature and then slowly cooling to relieve internal stresses and improve dimensional stability. This process enhances mechanical properties such as flexibility, toughness, and reduces the risk of warping or cracking during use. By annealing your plastic components, you ensure improved durability and extended product lifespan in various applications.

Purpose and Benefits of Tempering Plastics

Tempering plastics involves controlled heat treatment to enhance mechanical properties such as toughness and flexibility while reducing internal stresses formed during processing. This process improves dimensional stability and increases resistance to impact and cracking, extending the material's service life in demanding applications. Tempering also refines the polymer microstructure, resulting in improved performance under thermal and mechanical loads commonly encountered in industrial and consumer products.

Process Steps: Annealing vs. Tempering

Annealing plastics involves heating the material below its melting point to relieve internal stresses, holding it at a specific temperature, and then cooling it slowly to improve dimensional stability and reduce brittleness. Tempering plastics typically requires heating the material to a lower temperature than annealing, maintaining this temperature briefly, and cooling at a controlled rate to enhance toughness and impact resistance without significant dimensional changes. The key difference lies in the temperature profiles and cooling rates, where annealing prioritizes stress relief and crystallinity control, while tempering emphasizes mechanical property enhancement.

Impact on Mechanical Properties

Annealing in plastics improves ductility and reduces internal stresses by controlled heating and slow cooling, enhancing impact resistance and flexibility. Tempering adjusts the mechanical properties by reheating quenched plastics to a moderate temperature, increasing toughness and reducing brittleness without significant dimensional changes. Your choice between annealing and tempering depends on the desired balance of strength, hardness, and flexibility for the specific plastic application.

Applications of Annealed and Tempered Plastics

Annealed plastics are commonly used in applications requiring enhanced dimensional stability and reduced internal stresses, such as in precision manufacturing, optical components, and medical devices. Tempered plastics find their primary applications in environments demanding increased mechanical strength, impact resistance, and heat tolerance, including automotive parts, electronic housings, and protective gear. Your choice between annealed and tempered plastics depends on whether your project prioritizes stress relief and dimensional control or toughness and durability.

Choosing the Right Heat Treatment for Plastics

Annealing and tempering are critical heat treatment processes for enhancing the mechanical properties of plastics, with annealing primarily aimed at relieving internal stresses and improving dimensional stability by slowly cooling the material. Tempering, on the other hand, involves reheating the plastic to a specific temperature below its melting point to increase toughness and reduce brittleness while maintaining strength. Selecting the right heat treatment depends on the plastic type, desired property adjustments, and application requirements, making precise temperature control and duration essential for optimal performance.

Annealing vs tempering (plastics context) Infographic

libmatt.com

libmatt.com