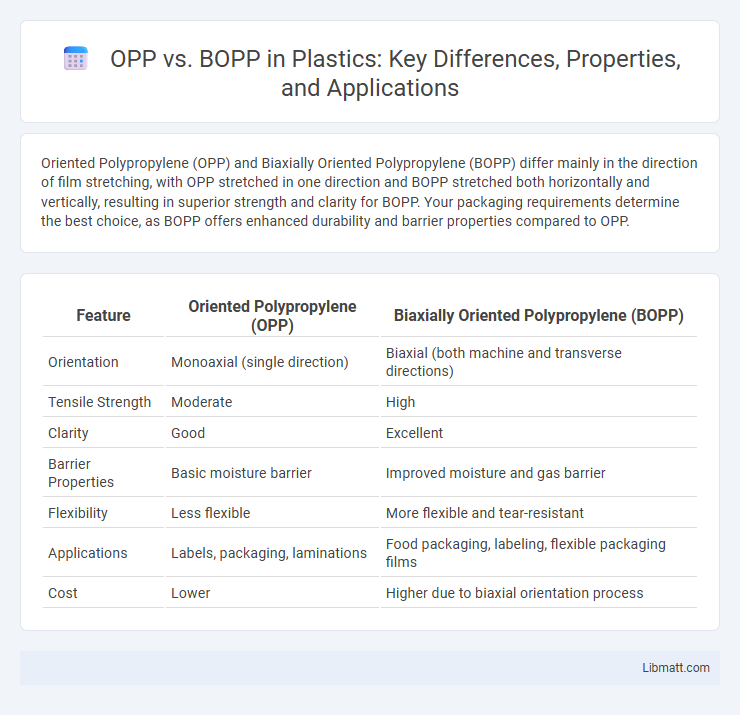

Oriented Polypropylene (OPP) and Biaxially Oriented Polypropylene (BOPP) differ mainly in the direction of film stretching, with OPP stretched in one direction and BOPP stretched both horizontally and vertically, resulting in superior strength and clarity for BOPP. Your packaging requirements determine the best choice, as BOPP offers enhanced durability and barrier properties compared to OPP.

Table of Comparison

| Feature | Oriented Polypropylene (OPP) | Biaxially Oriented Polypropylene (BOPP) |

|---|---|---|

| Orientation | Monoaxial (single direction) | Biaxial (both machine and transverse directions) |

| Tensile Strength | Moderate | High |

| Clarity | Good | Excellent |

| Barrier Properties | Basic moisture barrier | Improved moisture and gas barrier |

| Flexibility | Less flexible | More flexible and tear-resistant |

| Applications | Labels, packaging, laminations | Food packaging, labeling, flexible packaging films |

| Cost | Lower | Higher due to biaxial orientation process |

Introduction to Oriented Polypropylene (OPP) and BOPP

Oriented Polypropylene (OPP) is a versatile polymer film created by stretching polypropylene in one direction to enhance its strength and clarity. Biaxially Oriented Polypropylene (BOPP) undergoes stretching in both the machine and transverse directions, delivering superior tensile strength, clarity, and barrier properties compared to OPP. Your packaging or labeling projects benefit from choosing between OPP and BOPP based on the required durability, appearance, and moisture resistance.

Defining OPP and BOPP: Key Differences

Oriented Polypropylene (OPP) is a type of polypropylene film stretched in one direction to enhance strength and clarity, while Biaxially Oriented Polypropylene (BOPP) undergoes stretching in both machine and transverse directions, resulting in improved tensile strength, barrier properties, and stiffness. BOPP films are commonly used in packaging applications demanding superior resistance to moisture and gases compared to uniaxially oriented OPP films. The biaxial orientation process gives BOPP enhanced durability and optical qualities, making it preferable for food packaging and labels over standard OPP.

Manufacturing Processes of OPP vs BOPP

Oriented Polypropylene (OPP) is produced through a unidirectional stretching process, aligning polymer chains either in the machine direction or transverse direction to enhance clarity and strength. Biaxially Oriented Polypropylene (BOPP) undergoes stretching in both machine and transverse directions, resulting in superior mechanical properties, greater stiffness, and improved barrier performance. Understanding the difference in manufacturing processes can help optimize your packaging needs by selecting the film with the appropriate orientation for durability and printability.

Physical Properties Comparison: OPP vs BOPP

Oriented Polypropylene (OPP) and Biaxially Oriented Polypropylene (BOPP) differ significantly in their physical properties due to their manufacturing processes. OPP is stretched in a single direction, offering good tensile strength and clarity, whereas BOPP is stretched both longitudinally and transversely, resulting in superior mechanical strength, dimensional stability, and barrier properties. Your choice between OPP and BOPP should consider BOPP's enhanced durability and resistance to moisture and chemicals for packaging applications requiring higher performance.

Performance Advantages of OPP Films

Oriented Polypropylene (OPP) films exhibit superior clarity, stiffness, and barrier properties compared to Biaxially Oriented Polypropylene (BOPP), enhancing packaging durability and product shelf life. OPP films provide excellent moisture resistance and tensile strength, making them ideal for flexible packaging in food and consumer goods industries. Their enhanced optical properties and printability enable high-quality graphics, improving brand visibility and consumer appeal.

Benefits and Applications of BOPP Films

Biaxially Oriented Polypropylene (BOPP) films offer superior clarity, high tensile strength, and excellent moisture barrier properties, making them ideal for packaging applications that require durability and product visibility. These films are widely used in food packaging, labeling, and lamination due to their resistance to oils, fats, and chemicals, enhancing shelf life and product protection. The combination of cost-effectiveness and versatile performance positions BOPP films as a preferred choice over Oriented Polypropylene (OPP) in industrial and consumer packaging sectors.

Packaging Applications: OPP vs BOPP

Oriented Polypropylene (OPP) and Bi-Axially Oriented Polypropylene (BOPP) both excel in packaging applications due to their strength, clarity, and moisture resistance. BOPP offers enhanced barrier properties and durability because it is stretched in two directions, making it ideal for food packaging, labels, and flexible packaging films. Your choice between OPP and BOPP should depend on the specific requirements for packaging strength, transparency, and barrier performance.

Cost Analysis and Economic Considerations

Oriented Polypropylene (OPP) and Biaxially Oriented Polypropylene (BOPP) differ significantly in cost and economic impact, with BOPP typically incurring higher production expenses due to its biaxial orientation process, which enhances strength and clarity. The increased manufacturing complexity of BOPP leads to higher raw material and energy consumption, making it more expensive but economically viable for premium packaging requiring superior barrier properties. In contrast, OPP offers a cost-effective alternative with lower processing costs, suitable for applications where budget constraints outweigh the need for enhanced mechanical and barrier performance.

Environmental Impact: OPP vs BOPP Sustainability

BOPP (Biaxially Oriented Polypropylene) offers enhanced mechanical properties and is generally more recyclable than conventional OPP (Oriented Polypropylene), which improves your packaging's environmental performance. Both OPP and BOPP films are derived from polypropylene and are recyclable, but BOPP's biaxial orientation provides better barrier properties, reducing material usage and waste. Choosing BOPP can support sustainability goals by optimizing resource efficiency and facilitating more effective recycling processes.

Choosing Between OPP and BOPP: Factors to Consider

Choosing between Oriented Polypropylene (OPP) and Biaxially Oriented Polypropylene (BOPP) depends on your packaging needs, such as the desired barrier properties, clarity, and mechanical strength. OPP offers excellent clarity and stiffness for lightweight packaging, while BOPP provides superior tensile strength and moisture resistance due to its biaxial orientation. Consider factors like product protection, shelf appeal, and environmental impact when selecting the optimal film for your application.

Oriented Polypropylene (OPP) vs BOPP Infographic

libmatt.com

libmatt.com