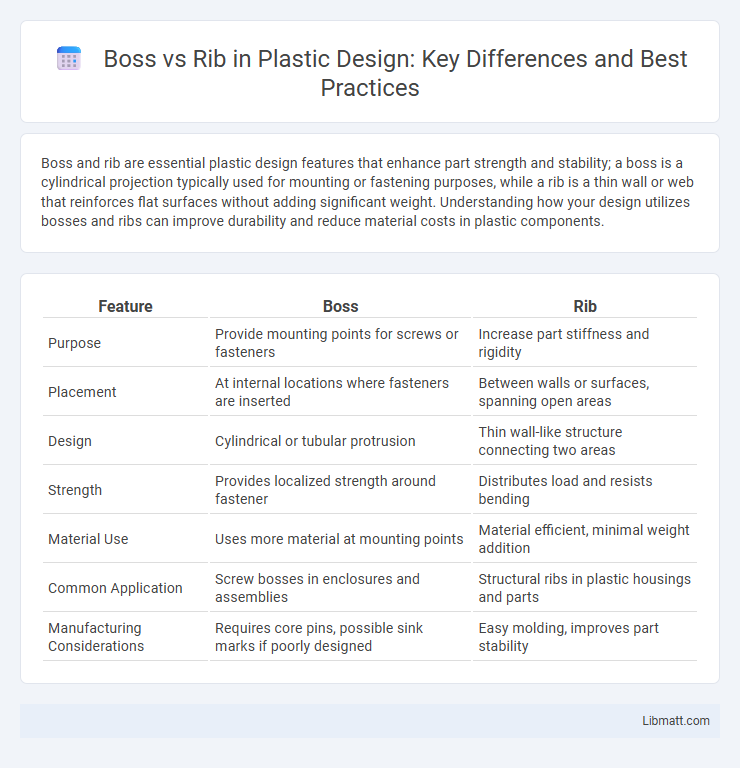

Boss and rib are essential plastic design features that enhance part strength and stability; a boss is a cylindrical projection typically used for mounting or fastening purposes, while a rib is a thin wall or web that reinforces flat surfaces without adding significant weight. Understanding how your design utilizes bosses and ribs can improve durability and reduce material costs in plastic components.

Table of Comparison

| Feature | Boss | Rib |

|---|---|---|

| Purpose | Provide mounting points for screws or fasteners | Increase part stiffness and rigidity |

| Placement | At internal locations where fasteners are inserted | Between walls or surfaces, spanning open areas |

| Design | Cylindrical or tubular protrusion | Thin wall-like structure connecting two areas |

| Strength | Provides localized strength around fastener | Distributes load and resists bending |

| Material Use | Uses more material at mounting points | Material efficient, minimal weight addition |

| Common Application | Screw bosses in enclosures and assemblies | Structural ribs in plastic housings and parts |

| Manufacturing Considerations | Requires core pins, possible sink marks if poorly designed | Easy molding, improves part stability |

Introduction to Boss and Rib Features in Plastic Design

Bosses and ribs are fundamental features in plastic design that enhance structural integrity and assembly efficiency. Bosses serve as cylindrical protrusions providing mounting points for screws or fasteners, ensuring secure component attachment. Ribs are thin, reinforcing walls that increase stiffness and reduce material usage while preventing warping and improving load distribution in molded parts.

Key Functions of Bosses and Ribs in Plastic Parts

Bosses in plastic parts provide essential support for screws and fasteners, ensuring secure assembly and alignment of components. Ribs enhance structural integrity and stiffness without significantly increasing material usage, preventing warping and improving load distribution. Your plastic design benefits from strategically placed bosses and ribs to balance strength, weight, and manufacturability effectively.

Structural Differences Between Bosses and Ribs

Bosses in plastic design are cylindrical protrusions primarily used for housing screws or fasteners, providing localized support and load distribution. Ribs are thin, vertical or angled walls integrated into the plastic part to enhance stiffness and reduce flex, optimizing overall structural integrity. The key structural difference lies in bosses offering point reinforcement for assembly, while ribs deliver broad reinforcement for enhanced rigidity.

Design Guidelines for Bosses in Plastics

Boss design in plastics requires careful consideration of wall thickness, draft angles, and fillet radii to prevent sink marks and ensure structural integrity. Maintaining a boss root thickness at about 60-80% of the adjacent wall thickness minimizes stress concentration and reduces the risk of cracking. Your design should include a draft angle of at least 1-2 degrees and smooth fillets to promote proper molding and assembly.

Design Guidelines for Ribs in Plastics

Boss and rib design in plastics requires adherence to specific guidelines to ensure structural integrity and manufacturability. Ribs should have a thickness of 40-60% of the adjacent wall to prevent sink marks and minimize residual stress, while bosses typically maintain a consistent wall thickness to avoid shrinkage defects. Your plastic component's durability is enhanced by aligning rib height to thickness ratios between 2:1 and 3:1, optimizing rigidity without causing warpage or mold filling issues.

Load Distribution: Boss vs. Rib

Bosses concentrate load at a single, often cylindrical, point designed for screw insertion or component mounting, which can create stress concentrations if not properly dimensioned. Ribs distribute loads more evenly across a broader section, enhancing structural stiffness and reducing deformation under stress by increasing the moment of inertia in plastic parts. Optimizing the balance between boss and rib placement in plastic design improves durability and minimizes failure due to stress concentration or flexing.

Common Defects: Bosses vs. Ribs in Injection Molding

Common defects in bosses include sink marks, warping, and cracking due to uneven cooling or inappropriate wall thickness, while ribs often suffer from sink marks, warpage, and stress concentrations if improperly designed. Bosses require careful thickness transition to avoid internal voids, whereas ribs need optimized height and thickness ratios to minimize mold filling issues and maintain structural integrity. You can improve overall part quality by balancing boss and rib design parameters to reduce defects and ensure dimensional stability in injection molded plastic parts.

Material Flow Considerations for Bosses and Ribs

Material flow considerations for bosses and ribs in plastic design are critical to ensuring structural integrity and avoiding defects such as sink marks and warping. Bosses require careful drafting and consistent wall thickness to facilitate uniform material flow and reduce stress concentration, while ribs should be designed with gradual thickness transitions and proper spacing to enhance rigidity without impeding material flow. Optimizing gate location, flow paths, and cooling rates further ensures even filling and solidification, minimizing issues related to shrinkage and weld lines in complex molded parts.

Cost Implications of Boss and Rib Designs

Boss and rib designs in plastic components significantly influence manufacturing costs, with bosses generally increasing material usage and cycle time due to their bulkier structure. Ribs, designed to reinforce parts without adding excessive material, offer a cost-effective alternative by enhancing strength while minimizing plastic consumption. Optimizing your design by balancing boss placement and rib integration can reduce overall part weight and tooling expenses, directly impacting production budgets.

Best Practices for Integrating Bosses and Ribs in Plastic Components

Integrating bosses and ribs in plastic components enhances structural integrity and supports fastening points without excessive material use. Design bosses with proper wall thickness and fillets to minimize sink marks and ensure uniform cooling, while ribs should maintain a thickness of 50-60% of the adjacent wall to prevent sink and warpage. Your plastic parts achieve optimal strength and manufacturing efficiency when these best practices balance mechanical requirements with moldability.

Boss vs rib (plastic design) Infographic

libmatt.com

libmatt.com