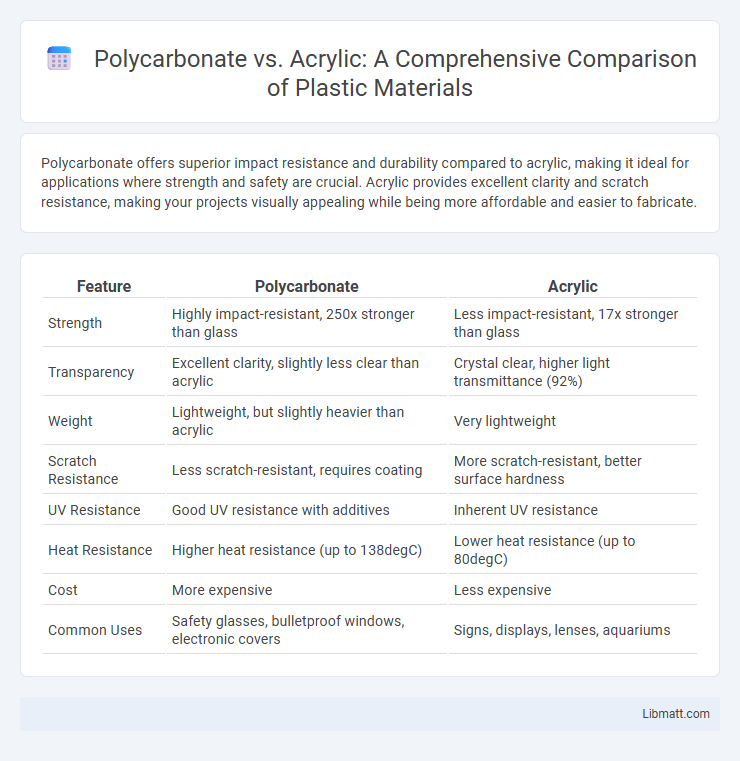

Polycarbonate offers superior impact resistance and durability compared to acrylic, making it ideal for applications where strength and safety are crucial. Acrylic provides excellent clarity and scratch resistance, making your projects visually appealing while being more affordable and easier to fabricate.

Table of Comparison

| Feature | Polycarbonate | Acrylic |

|---|---|---|

| Strength | Highly impact-resistant, 250x stronger than glass | Less impact-resistant, 17x stronger than glass |

| Transparency | Excellent clarity, slightly less clear than acrylic | Crystal clear, higher light transmittance (92%) |

| Weight | Lightweight, but slightly heavier than acrylic | Very lightweight |

| Scratch Resistance | Less scratch-resistant, requires coating | More scratch-resistant, better surface hardness |

| UV Resistance | Good UV resistance with additives | Inherent UV resistance |

| Heat Resistance | Higher heat resistance (up to 138degC) | Lower heat resistance (up to 80degC) |

| Cost | More expensive | Less expensive |

| Common Uses | Safety glasses, bulletproof windows, electronic covers | Signs, displays, lenses, aquariums |

Introduction to Polycarbonate and Acrylic

Polycarbonate and acrylic are popular transparent thermoplastics widely used for their clarity, impact resistance, and versatility. Polycarbonate offers superior durability and high impact strength, making it suitable for safety applications, while acrylic is favored for its excellent optical clarity and weather resistance. Your selection between polycarbonate and acrylic depends on specific needs like toughness, UV stability, and cost-effectiveness.

Key Differences Between Polycarbonate and Acrylic

Polycarbonate offers higher impact resistance and greater durability compared to acrylic, making it suitable for applications requiring toughness and safety, such as protective barriers and eyewear lenses. Acrylic provides superior optical clarity and scratch resistance, often used in display cases, signage, and lighting covers where transparency and aesthetic appeal are critical. Both materials differ in chemical resistance and cost, with polycarbonate generally being more expensive but offering better heat resistance and flexibility.

Strength and Durability Comparison

Polycarbonate is significantly stronger than acrylic, offering impact resistance up to 250 times greater than glass, making it ideal for applications requiring high durability. Acrylic, while more scratch-resistant and UV-stable, is more prone to cracking under stress compared to polycarbonate. Your choice should weigh polycarbonate's superior toughness against acrylic's better abrasion resistance depending on the strength and longevity needed.

Optical Clarity and Light Transmission

Polycarbonate offers exceptional optical clarity with a light transmission rate of approximately 88-90%, making it highly durable and impact-resistant while maintaining transparency. Acrylic provides superior light transmission of about 92%, delivering crystal-clear clarity and better scratch resistance but is more brittle compared to polycarbonate. Both materials are widely used in applications requiring clear visibility, though acrylic excels in optical clarity, whereas polycarbonate balances clarity with toughness.

Impact Resistance: Which is Tougher?

Polycarbonate offers significantly higher impact resistance compared to acrylic, making it tougher and more suitable for applications requiring durability and shatter resistance. It can withstand impacts up to 250 times greater than glass, whereas acrylic provides good clarity but is more prone to cracking under stress. This superior toughness makes polycarbonate ideal for protective gear, safety windows, and high-impact glazing.

Weight and Handling Differences

Polycarbonate is significantly lighter than acrylic, making it easier to handle and more suitable for applications requiring frequent manipulation or mounting. While polycarbonate offers superior impact resistance and flexibility, acrylic is stiffer but more prone to cracking under stress. Considering weight and handling, your choice depends on whether durability or structural rigidity is the priority for your project.

Weather and UV Resistance

Polycarbonate offers superior weather and UV resistance compared to acrylic, making it ideal for outdoor applications exposed to harsh sunlight and extreme temperatures. Its UV-resistant coatings protect against yellowing and degradation, ensuring long-lasting clarity and durability. Acrylic, while resistant to UV rays, tends to become brittle and may yellow over time when subjected to prolonged sun exposure.

Cost Analysis: Polycarbonate vs Acrylic

Polycarbonate is generally more expensive than acrylic due to its superior impact resistance and durability, making it a cost-effective choice for long-term applications. Acrylic is more affordable initially, ideal for budget-sensitive projects, but it may require more frequent replacements due to lower impact resistance. Evaluating your project's lifespan and performance needs will help determine whether the higher upfront cost of polycarbonate justifies its extended durability over acrylic.

Common Applications for Each Material

Polycarbonate is widely used in safety equipment, such as helmets, bulletproof windows, and protective eyewear, due to its high impact resistance and durability. Acrylic is favored for display cases, signage, and skylights because of its clarity, weather resistance, and ease of fabrication. Both materials serve distinct roles in automotive, architectural, and lighting industries, chosen based on performance requirements like strength and optical properties.

Choosing the Right Material for Your Project

Polycarbonate offers superior impact resistance and UV protection, making it ideal for applications requiring durability and weather resistance, such as safety glazing and outdoor signage. Acrylic provides excellent optical clarity and scratch resistance at a lower cost, suitable for display cases, aquariums, and decorative panels. Consider project requirements including strength, transparency, weather exposure, and budget to select the most appropriate material between polycarbonate and acrylic.

Polycarbonate vs Acrylic Infographic

libmatt.com

libmatt.com