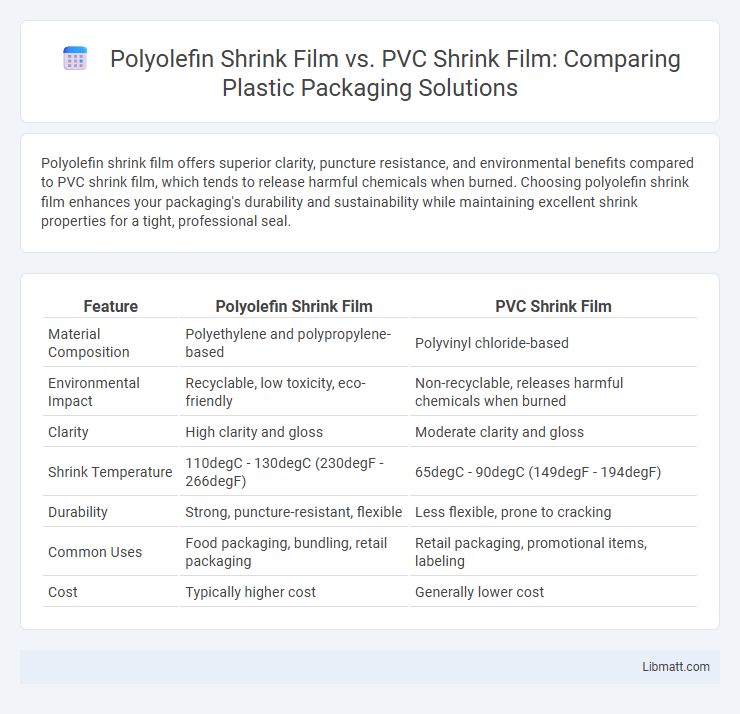

Polyolefin shrink film offers superior clarity, puncture resistance, and environmental benefits compared to PVC shrink film, which tends to release harmful chemicals when burned. Choosing polyolefin shrink film enhances your packaging's durability and sustainability while maintaining excellent shrink properties for a tight, professional seal.

Table of Comparison

| Feature | Polyolefin Shrink Film | PVC Shrink Film |

|---|---|---|

| Material Composition | Polyethylene and polypropylene-based | Polyvinyl chloride-based |

| Environmental Impact | Recyclable, low toxicity, eco-friendly | Non-recyclable, releases harmful chemicals when burned |

| Clarity | High clarity and gloss | Moderate clarity and gloss |

| Shrink Temperature | 110degC - 130degC (230degF - 266degF) | 65degC - 90degC (149degF - 194degF) |

| Durability | Strong, puncture-resistant, flexible | Less flexible, prone to cracking |

| Common Uses | Food packaging, bundling, retail packaging | Retail packaging, promotional items, labeling |

| Cost | Typically higher cost | Generally lower cost |

Introduction to Shrink Films

Shrink films are versatile packaging materials designed to tightly conform to products when heated, providing protection and tamper evidence. Polyolefin shrink film offers superior clarity, puncture resistance, and eco-friendly attributes compared to PVC shrink film, which is known for its strong sealing properties but less environmental sustainability. Your choice between these films impacts package appearance, durability, and recyclability, making it important to consider specific application needs.

What is Polyolefin Shrink Film?

Polyolefin shrink film is a versatile packaging material made from polyolefin polymers, known for its clarity, strength, and flexibility. It provides excellent puncture and impact resistance while maintaining a safe, residue-free seal, making it ideal for food and retail packaging. Your products benefit from polyolefin shrink film's superior shrink properties and environmentally friendly composition compared to PVC shrink film alternatives.

What is PVC Shrink Film?

PVC shrink film is a type of plastic packaging material made from polyvinyl chloride, known for its clarity, flexibility, and strong shrink properties when exposed to heat. It is commonly used for bundling products, tamper-evident seals, and protective packaging due to its excellent sealing ability and durability. Compared to polyolefin shrink film, PVC shrink film offers superior stiffness and scratch resistance but may release harmful chlorine-based compounds during incineration.

Key Differences Between Polyolefin and PVC Shrink Film

Polyolefin shrink film offers superior clarity, flexibility, and puncture resistance compared to PVC shrink film, making it ideal for delicate or irregularly shaped products. PVC shrink film contains chlorine, which raises environmental and disposal concerns, whereas polyolefin is more eco-friendly and recyclable. Your choice between the two materials should consider product protection requirements, environmental impact, and regulatory compliance.

Durability and Strength Comparison

Polyolefin shrink film offers superior durability and strength compared to PVC shrink film, boasting higher tensile strength and improved puncture resistance, which ensures better protection for your packaged products. Polyolefin also exhibits enhanced flexibility and resistance to cracking, making it ideal for fragile or irregularly shaped items. In contrast, PVC shrink film tends to be less durable and may become brittle over time, reducing its effectiveness in long-term storage and transport.

Safety and Environmental Impact

Polyolefin shrink film offers superior safety due to its non-toxic composition and absence of chlorine, which reduces harmful dioxin emissions during disposal and incineration. PVC shrink film contains chlorine, posing significant environmental hazards through toxic gas release and longer degradation periods in landfills. Choosing polyolefin shrink film supports eco-friendly packaging by minimizing health risks and fostering sustainable waste management.

Clarity and Presentation Quality

Polyolefin shrink film offers superior clarity and a higher gloss finish compared to PVC shrink film, enhancing the visual appeal of packaged products. This improved transparency allows your items to stand out on shelves, providing a professional and attractive presentation that draws customer attention. PVC shrink film tends to have a slight haze, which can reduce the overall sharpness and vibrancy of your packaging.

Application Suitability and Versatility

Polyolefin shrink film offers superior clarity, flexibility, and puncture resistance, making it highly suitable for packaging irregularly shaped products and food items that require breathability. PVC shrink film provides excellent shrink properties and cost-effectiveness but is less versatile due to its lower resistance to heat and environmental factors. Your choice depends on the specific application needs, with polyolefin excelling in versatility and safety, while PVC remains a practical option for simple, low-cost packaging.

Cost Analysis: Polyolefin vs PVC Shrink Film

Polyolefin shrink film generally offers a more cost-effective solution compared to PVC shrink film due to its lower raw material and manufacturing expenses. While PVC shrink film may have a marginally cheaper initial price in some markets, the added costs related to environmental compliance and disposal make polyolefin more economical over time. Your business benefits from choosing polyolefin shrink film by reducing overall packaging costs and minimizing environmental impact fees.

Choosing the Right Shrink Film for Your Needs

Polyolefin shrink film offers superior clarity, greater puncture resistance, and is more environmentally friendly compared to PVC shrink film, which tends to be less flexible and releases harmful chemicals when burned. Your choice depends on factors like product sensitivity, environmental concerns, and packaging durability; polyolefin suits food packaging and delicate items, while PVC may be chosen for cost-sensitive applications. Evaluating these key characteristics ensures you select the most efficient shrink film tailored to your specific packaging requirements.

Polyolefin Shrink Film vs PVC Shrink Film Infographic

libmatt.com

libmatt.com