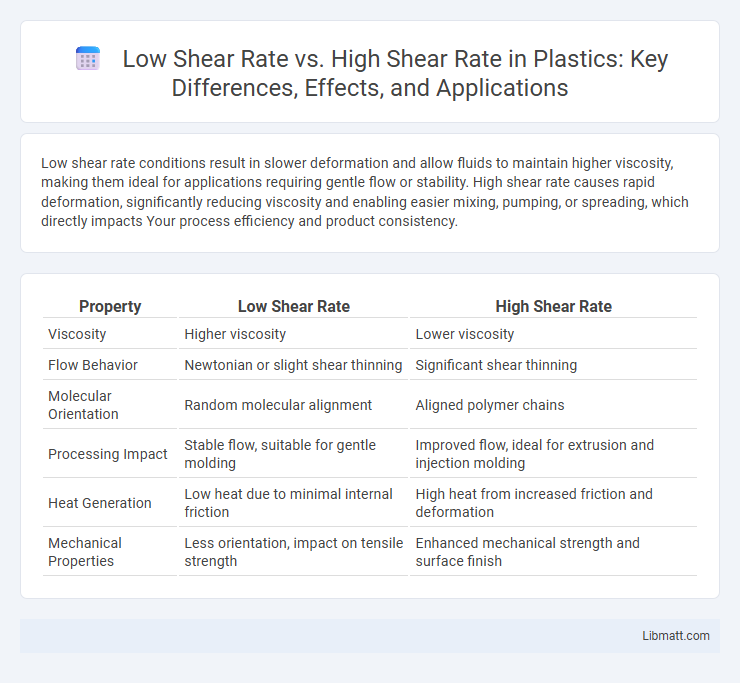

Low shear rate conditions result in slower deformation and allow fluids to maintain higher viscosity, making them ideal for applications requiring gentle flow or stability. High shear rate causes rapid deformation, significantly reducing viscosity and enabling easier mixing, pumping, or spreading, which directly impacts Your process efficiency and product consistency.

Table of Comparison

| Property | Low Shear Rate | High Shear Rate |

|---|---|---|

| Viscosity | Higher viscosity | Lower viscosity |

| Flow Behavior | Newtonian or slight shear thinning | Significant shear thinning |

| Molecular Orientation | Random molecular alignment | Aligned polymer chains |

| Processing Impact | Stable flow, suitable for gentle molding | Improved flow, ideal for extrusion and injection molding |

| Heat Generation | Low heat due to minimal internal friction | High heat from increased friction and deformation |

| Mechanical Properties | Less orientation, impact on tensile strength | Enhanced mechanical strength and surface finish |

Understanding Shear Rate: Definition and Importance

Shear rate measures the rate at which adjacent layers of fluid move relative to each other, critical in assessing fluid viscosity and flow behavior. Low shear rates occur in slow-moving or resting fluids, while high shear rates appear under rapid movement or stirring, influencing how fluids respond to stress. Understanding shear rate helps you optimize processes in industries like food, pharmaceuticals, and lubricants by predicting fluid performance under varying conditions.

Key Differences Between Low and High Shear Rates

Low shear rate refers to the slow deformation of fluids, resulting in minimal disruption of fluid structure and higher viscosity, commonly observed in laminar flow conditions. High shear rate involves rapid deformation, causing significant alignment or breakdown of fluid molecules, leading to decreased viscosity and turbulence in applications like mixing or injection molding. Key differences include the rate of fluid deformation, viscosity behavior (shear-thickening versus shear-thinning), and effects on material properties and processing efficiency.

Viscosity Behavior Under Low Shear vs High Shear

Viscosity behavior varies significantly between low shear rate and high shear rate conditions, with fluids often exhibiting higher viscosity at low shear rates due to stronger intermolecular forces and less molecular alignment. At high shear rates, viscosity typically decreases as fluid molecules align in the flow direction, reducing internal resistance and enabling easier movement. Understanding this shear-dependent viscosity behavior is crucial for optimizing processes where your fluid experiences varying flow conditions.

Applications of Low Shear Rate in Industry

Low shear rate processes are essential in industries such as food production, pharmaceuticals, and cosmetics, where gentle mixing preserves the integrity and texture of delicate products like creams, gels, and emulsions. In polymer manufacturing and coatings, low shear rates prevent molecular degradation, ensuring consistent viscosity and film formation. These applications benefit from controlled, minimal shear forces to maintain product stability, enhance quality, and extend shelf life.

Applications of High Shear Rate in Industry

High shear rate processes are essential in industries such as pharmaceuticals, food production, and cosmetics, where rapid mixing, emulsification, and dispersion improve product consistency and stability. High shear mixers enable the formation of fine particles and uniform droplets, enhancing bioavailability and texture in medicinal formulations and food products. Your manufacturing efficiency and product quality can significantly benefit from adopting high shear rate technologies in these applications.

Rheological Measurements: Tools and Techniques

Rheological measurements at low shear rates require sensitive rotational viscometers or rheometers capable of detecting subtle changes in viscosity and flow behavior, crucial for characterizing materials with yield stress or complex non-Newtonian properties. High shear rate measurements often utilize capillary rheometers or high-speed rotational devices to simulate processing conditions like extrusion or injection molding, providing insight into shear thinning or thickening behavior. Your selection of rheological tools depends on the shear rate range relevant to your application, ensuring accurate data for formulation, quality control, or process optimization.

Impact of Shear Rate on Fluid Dynamics

Shear rate significantly influences fluid viscosity, where low shear rates typically result in higher viscosity due to molecular alignment resistance, and high shear rates induce shear thinning, reducing viscosity and enhancing flow. This behavior directly affects fluid dynamics in applications such as lubrication, polymer processing, and blood flow, where controlling shear rate optimizes performance. Understanding the transition between Newtonian and non-Newtonian flow regimes is essential for predicting fluid behavior under varying shear conditions.

Real-World Examples: Low vs High Shear Rate Fluids

Low shear rate fluids, such as honey or toothpaste, exhibit thick, viscous behavior that slows flow under gentle forces, commonly seen when squeezing a tube or pouring slowly. High shear rate fluids like water or thin oils flow easily and rapidly under strong forces, typical in industrial processes involving pumps or high-speed mixers. Understanding these differences is crucial for applications like food processing, cosmetics formulation, and lubrication systems where fluid behavior impacts performance and efficiency.

Challenges in Controlling Shear Rates

Controlling shear rates presents significant challenges due to the complex behavior of non-Newtonian fluids, which exhibit variable viscosity under different shear conditions. At low shear rates, fluids may show high viscosity and elastic effects, complicating precise control in processes like coating or food production. Conversely, high shear rates can cause shear thinning or thickening, making consistent flow behavior difficult to maintain and requiring advanced rheological instruments for accurate monitoring.

Future Trends in Shear Rate Research and Applications

Future trends in shear rate research emphasize the development of advanced rheological models that accurately predict material behavior across varying shear rates, enhancing processing efficiency in industries such as biopolymers and advanced composites. Innovations in microfluidics and nanotechnology enable precise manipulation at low shear rates, critical for biomedical applications like drug delivery systems and tissue engineering. High shear rate applications are advancing with improved computational simulations and novel materials that withstand extreme stresses, optimizing manufacturing processes in sectors like aerospace and automotive engineering.

Low Shear Rate vs High Shear Rate Infographic

libmatt.com

libmatt.com