Engineering plastics offer superior mechanical properties, heat resistance, and durability compared to commodity plastics, making them ideal for demanding applications in automotive, aerospace, and electronics industries. Your choice between the two depends on the specific performance requirements, cost considerations, and environmental conditions of the intended use.

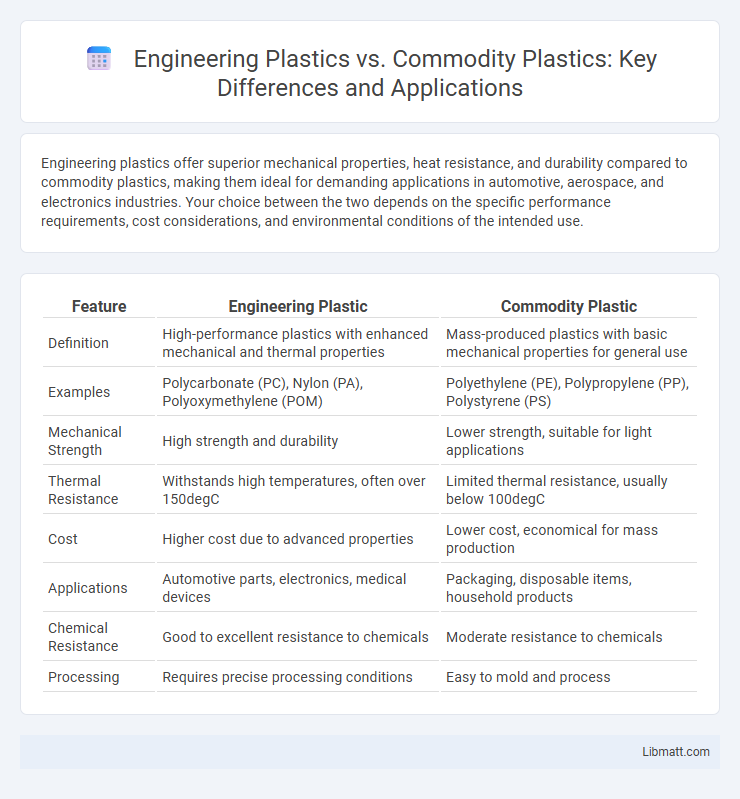

Table of Comparison

| Feature | Engineering Plastic | Commodity Plastic |

|---|---|---|

| Definition | High-performance plastics with enhanced mechanical and thermal properties | Mass-produced plastics with basic mechanical properties for general use |

| Examples | Polycarbonate (PC), Nylon (PA), Polyoxymethylene (POM) | Polyethylene (PE), Polypropylene (PP), Polystyrene (PS) |

| Mechanical Strength | High strength and durability | Lower strength, suitable for light applications |

| Thermal Resistance | Withstands high temperatures, often over 150degC | Limited thermal resistance, usually below 100degC |

| Cost | Higher cost due to advanced properties | Lower cost, economical for mass production |

| Applications | Automotive parts, electronics, medical devices | Packaging, disposable items, household products |

| Chemical Resistance | Good to excellent resistance to chemicals | Moderate resistance to chemicals |

| Processing | Requires precise processing conditions | Easy to mold and process |

Introduction to Engineering Plastics and Commodity Plastics

Engineering plastics, such as polycarbonate, polyamide (nylon), and PEEK, offer superior mechanical strength, thermal resistance, and chemical stability compared to commodity plastics like polyethylene, polypropylene, and polystyrene, which are primarily used for low-cost, high-volume applications. Commodity plastics dominate everyday packaging and consumer goods due to their ease of processing and low price, while engineering plastics are essential in automotive, aerospace, and electronics industries for demanding performance requirements. The distinct material properties and applications of engineering versus commodity plastics highlight the importance of selecting the appropriate polymer based on mechanical durability, temperature tolerance, and cost efficiency.

Key Definitions: What Are Engineering and Commodity Plastics?

Engineering plastics are high-performance polymers designed to withstand mechanical stress, heat, and chemical exposure, commonly used in automotive, aerospace, and electronics industries. Commodity plastics, such as polyethylene and polypropylene, are mass-produced polymers primarily valued for their low cost, ease of processing, and general-purpose applications in packaging and consumer goods. The fundamental difference lies in their mechanical properties, thermal stability, and cost, with engineering plastics offering superior durability and performance compared to commodity plastics.

Chemical Structure and Molecular Composition

Engineering plastics feature complex chemical structures with high molecular weight polymers and enhanced molecular branching, providing superior thermal stability and mechanical strength. Commodity plastics possess simpler molecular compositions, typically made of low-cost polymers like polyethylene and polypropylene with linear or lightly branched chains. The molecular architecture of engineering plastics allows for better resistance to chemicals and higher performance in demanding environments compared to commodity plastics.

Mechanical Properties: Strength, Durability, and Flexibility

Engineering plastics exhibit superior mechanical properties compared to commodity plastics, offering higher tensile strength and enhanced impact resistance essential for structural applications. Their durability withstands extreme temperatures and chemical exposure, making them suitable for long-term use in demanding environments. Flexibility varies among types but generally remains more controlled to maintain mechanical integrity, unlike commodity plastics which prioritize cost and ease of processing over mechanical performance.

Thermal Resistance and Temperature Performance

Engineering plastics exhibit superior thermal resistance and maintain structural integrity at higher temperatures, often exceeding 150degC, making them ideal for demanding applications. Commodity plastics typically withstand lower temperature ranges, generally below 100degC, and tend to deform or degrade when exposed to heat for prolonged periods. The enhanced temperature performance of engineering plastics enables their use in automotive, aerospace, and electrical components where heat stability is critical.

Common Applications in Various Industries

Engineering plastics are extensively used in automotive components, aerospace parts, and electrical insulation due to their high strength, thermal resistance, and durability. Commodity plastics, such as polyethylene and polypropylene, dominate packaging, disposable containers, and household goods because of their low cost and ease of processing. The distinct material properties drive their applications, with engineering plastics favored for performance-critical uses and commodity plastics preferred for mass-produced, cost-sensitive products.

Cost Comparison: Price and Economic Considerations

Engineering plastics generally have a higher cost than commodity plastics due to their superior mechanical properties, chemical resistance, and thermal stability. Commodity plastics, such as polyethylene and polypropylene, offer low-cost solutions ideal for mass production and applications with less demanding performance requirements. Understanding your project's budget constraints and performance needs will help determine whether the investment in engineering plastics justifies the economic benefit over commodity plastics.

Environmental Impact and Sustainability Factors

Engineering plastics typically offer enhanced durability and longer service life compared to commodity plastics, reducing the frequency of replacement and overall waste generation. However, engineering plastics often require more energy and resources to produce, which can increase their environmental footprint during manufacturing. Your choice between these plastics should consider the trade-off between advanced performance and the potential for recycling or biodegradability to optimize sustainability.

Selection Criteria: Choosing the Right Plastic for Your Project

Selection criteria for engineering plastics versus commodity plastics revolve around performance requirements, cost, and environmental conditions. Engineering plastics, such as polycarbonate, ABS, and PEEK, offer superior mechanical strength, thermal stability, and chemical resistance, making them ideal for demanding applications in automotive, aerospace, and electronics. Commodity plastics like polyethylene and polypropylene are chosen for cost-sensitive, high-volume production where moderate durability and flexibility meet the project's basic functional needs.

Future Trends in Plastic Technology

Future trends in plastic technology highlight a growing shift toward engineering plastics due to their superior mechanical properties, thermal stability, and chemical resistance compared to commodity plastics. Innovations in bio-based engineering plastics and enhanced recycling methods are driving sustainability efforts while meeting demanding industry requirements. Your choice of plastic materials will increasingly benefit from advanced formulations that balance performance with environmental impact.

Engineering plastic vs commodity plastic Infographic

libmatt.com

libmatt.com