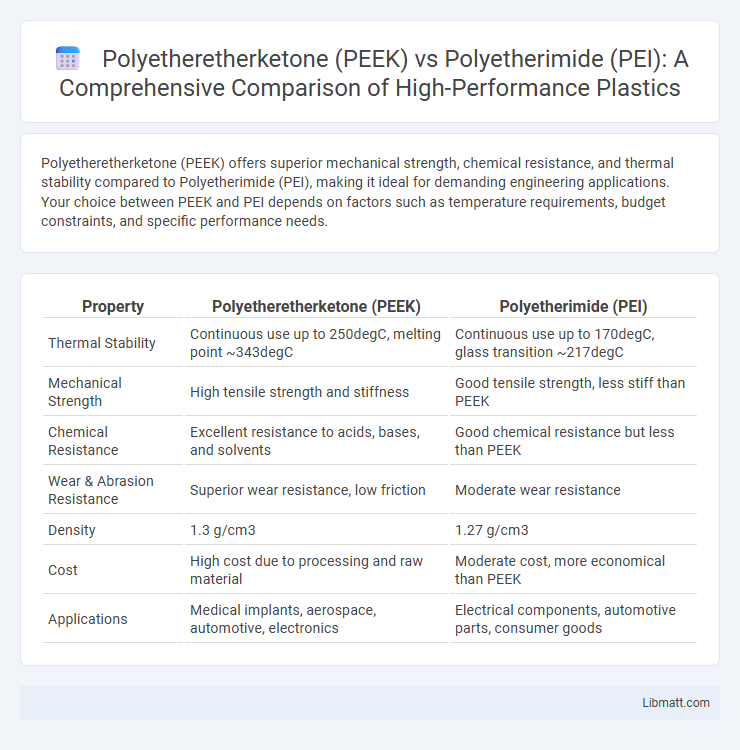

Polyetheretherketone (PEEK) offers superior mechanical strength, chemical resistance, and thermal stability compared to Polyetherimide (PEI), making it ideal for demanding engineering applications. Your choice between PEEK and PEI depends on factors such as temperature requirements, budget constraints, and specific performance needs.

Table of Comparison

| Property | Polyetheretherketone (PEEK) | Polyetherimide (PEI) |

|---|---|---|

| Thermal Stability | Continuous use up to 250degC, melting point ~343degC | Continuous use up to 170degC, glass transition ~217degC |

| Mechanical Strength | High tensile strength and stiffness | Good tensile strength, less stiff than PEEK |

| Chemical Resistance | Excellent resistance to acids, bases, and solvents | Good chemical resistance but less than PEEK |

| Wear & Abrasion Resistance | Superior wear resistance, low friction | Moderate wear resistance |

| Density | 1.3 g/cm3 | 1.27 g/cm3 |

| Cost | High cost due to processing and raw material | Moderate cost, more economical than PEEK |

| Applications | Medical implants, aerospace, automotive, electronics | Electrical components, automotive parts, consumer goods |

Introduction to PEEK and PEI

Polyetheretherketone (PEEK) and Polyetherimide (PEI) are high-performance thermoplastics known for their exceptional mechanical strength, thermal stability, and chemical resistance in demanding applications. PEEK offers superior resistance to heat up to 250degC and excellent wear properties, making it ideal for aerospace and medical devices. PEI provides notable dimensional stability and flame retardancy with a continuous use temperature around 170degC, making Your selection dependent on the specific thermal and mechanical requirements of the application.

Chemical Structure and Composition

Polyetheretherketone (PEEK) is a semi-crystalline thermoplastic characterized by repeating units of ether and ketone groups that contribute to its high thermal stability and chemical resistance. Polyetherimide (PEI) is an amorphous polymer comprising imide and ether linkages that provide excellent dimensional stability and hydrolytic resistance. The presence of ketone groups in PEEK's backbone contrasts with the imide groups in PEI, influencing their mechanical properties and applicability in high-performance engineering environments.

Mechanical Properties Comparison

Polyetheretherketone (PEEK) exhibits superior tensile strength and impact resistance compared to Polyetherimide (PEI), making it ideal for high-stress applications. PEI offers excellent dimensional stability and high heat resistance, but its mechanical strength is generally lower than PEEK's, especially under prolonged load or extreme temperatures. Your choice between PEEK and PEI should consider the specific mechanical demands and operating environment of your application.

Thermal Stability and Operating Temperatures

Polyetheretherketone (PEEK) offers superior thermal stability with a continuous operating temperature of around 260degC, making it ideal for high-temperature applications requiring long-term heat resistance. Polyetherimide (PEI) withstands continuous use at temperatures up to 170degC, providing excellent performance in moderately high-temperature environments while maintaining strength and dimensional stability. Understanding these differences helps you select the right polymer for your project's thermal demands.

Electrical and Dielectric Performance

Polyetheretherketone (PEEK) exhibits superior dielectric strength and lower dielectric constant compared to Polyetherimide (PEI), making it highly suitable for high-frequency electrical insulation applications. PEEK maintains stable electrical properties across a wide temperature range up to 250degC, whereas PEI's electrical performance begins to degrade at lower temperatures around 170degC. The low dielectric loss and excellent insulating capabilities of PEEK offer enhanced reliability in demanding environments compared to the relatively moderate electrical performance of PEI.

Chemical Resistance and Environmental Durability

Polyetheretherketone (PEEK) exhibits superior chemical resistance compared to Polyetherimide (PEI), withstanding aggressive solvents, acids, and alkalis without significant degradation. PEEK's molecular structure provides exceptional environmental durability, maintaining mechanical properties under high temperature, moisture, and UV exposure conditions. While PEI offers good chemical resistance, it is more susceptible to hydrolysis and environmental stress cracking, making PEEK the preferred choice for harsh chemical and demanding environmental applications.

Processability and Manufacturing Techniques

Polyetheretherketone (PEEK) offers excellent processability through techniques such as injection molding, extrusion, and compression molding, with a high melting point around 343degC facilitating durable component fabrication. Polyetherimide (PEI) processes well via injection molding and thermoforming but lacks a true melting point, requiring careful control during processing to avoid degradation. Your choice between PEEK and PEI should consider manufacturing intricacies, as PEEK generally provides wider thermal processing windows and superior mechanical stability under high temperatures.

Applications in Industry

Polyetheretherketone (PEEK) is widely used in aerospace, automotive, and medical industries due to its exceptional mechanical strength, chemical resistance, and high-temperature stability up to 260degC. Polyetherimide (PEI) finds applications in electronics, electrical insulation, and medical devices, benefiting from its excellent dimensional stability, flame resistance, and performance at temperatures up to 170degC. Both polymers serve critical roles in manufacturing components requiring durability and thermal resistance, with PEEK favored for high-stress environments and PEI preferred for cost-effective, high-performance engineering plastics.

Cost Analysis and Availability

Polyetheretherketone (PEEK) typically commands a higher price due to its superior mechanical properties and chemical resistance, making it a premium choice for demanding applications. Polyetherimide (PEI) offers a more cost-effective solution with good thermal stability and strength, widely available through various suppliers. Availability of PEI exceeds that of PEEK in standard industrial markets, supporting broader adoption in cost-sensitive manufacturing sectors.

Choosing Between PEEK and PEI: Key Considerations

When choosing between Polyetheretherketone (PEEK) and Polyetherimide (PEI), consider factors such as thermal stability, mechanical strength, and chemical resistance. PEEK offers superior high-temperature performance up to 260degC and exceptional chemical resistance, making it ideal for demanding industrial applications. Your selection should align with the specific thermal and mechanical requirements of your project to ensure optimal material performance.

Polyetheretherketone (PEEK) vs Polyetherimide (PEI) Infographic

libmatt.com

libmatt.com