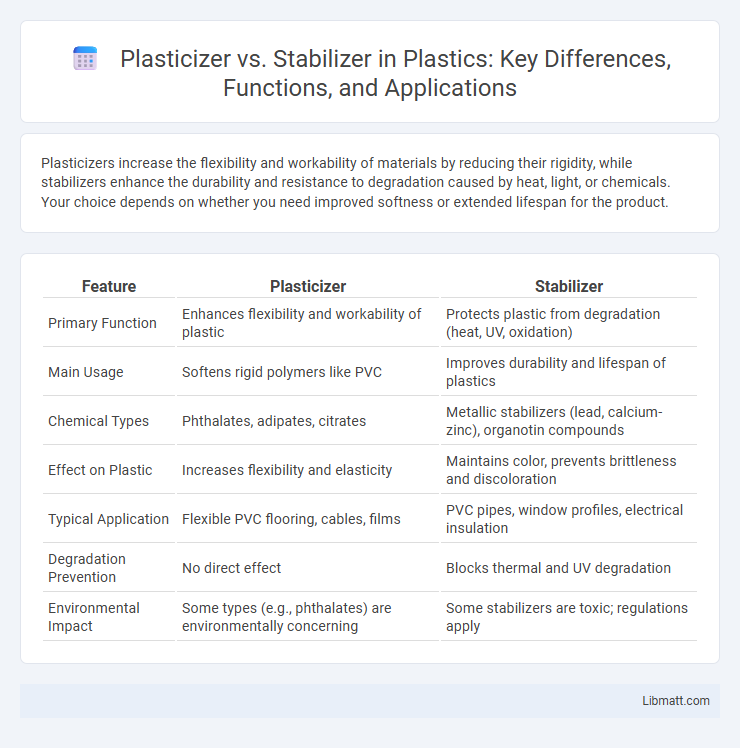

Plasticizers increase the flexibility and workability of materials by reducing their rigidity, while stabilizers enhance the durability and resistance to degradation caused by heat, light, or chemicals. Your choice depends on whether you need improved softness or extended lifespan for the product.

Table of Comparison

| Feature | Plasticizer | Stabilizer |

|---|---|---|

| Primary Function | Enhances flexibility and workability of plastic | Protects plastic from degradation (heat, UV, oxidation) |

| Main Usage | Softens rigid polymers like PVC | Improves durability and lifespan of plastics |

| Chemical Types | Phthalates, adipates, citrates | Metallic stabilizers (lead, calcium-zinc), organotin compounds |

| Effect on Plastic | Increases flexibility and elasticity | Maintains color, prevents brittleness and discoloration |

| Typical Application | Flexible PVC flooring, cables, films | PVC pipes, window profiles, electrical insulation |

| Degradation Prevention | No direct effect | Blocks thermal and UV degradation |

| Environmental Impact | Some types (e.g., phthalates) are environmentally concerning | Some stabilizers are toxic; regulations apply |

Introduction to Plasticizers and Stabilizers

Plasticizers are additives used in polymers to increase flexibility, workability, and durability by reducing intermolecular forces. Stabilizers enhance the material's resistance to degradation from heat, UV radiation, and oxidation, prolonging the lifespan of plastics. Your choice between plasticizers and stabilizers depends on the specific performance requirements of the polymer application.

Defining Plasticizers: Functions and Applications

Plasticizers are additives that increase the flexibility and workability of polymers by reducing intermolecular forces, commonly used in PVC to enhance softness and durability. Their primary function is to improve material elasticity and processability in applications such as cables, flooring, and toys. Plasticizers differ from stabilizers, which focus on preserving polymer integrity by preventing degradation from heat, UV radiation, and oxidative stress.

Understanding Stabilizers: Roles and Importance

Stabilizers play a crucial role in enhancing the durability and performance of polymer materials by preventing degradation caused by heat, light, and oxygen exposure. They work by neutralizing free radicals and decomposing peroxides, thereby maintaining the polymer's structural integrity during processing and throughout its lifespan. Unlike plasticizers that increase flexibility, stabilizers ensure long-term stability, making them essential for applications requiring resistance to environmental stressors.

Key Differences Between Plasticizers and Stabilizers

Plasticizers increase the flexibility and workability of polymers by reducing intermolecular forces, while stabilizers enhance the durability and longevity of materials by protecting against degradation from heat, light, and oxygen. Plasticizers are primarily used to soften rigid plastics such as PVC, whereas stabilizers prevent discoloration and maintain physical properties in various plastics and rubbers. Key differences lie in their functional roles: plasticizers improve elasticity and processing, whereas stabilizers guard against chemical breakdown and environmental damage.

Common Types of Plasticizers Used in Industry

Common types of plasticizers used in industry include phthalates, adipates, and citrates, each enhancing flexibility and durability in polymers like PVC. Phthalates remain the most widely used due to their excellent compatibility and cost-effectiveness, while adipates offer superior low-temperature performance. Selecting the right plasticizer impacts your product's mechanical properties and environmental compliance.

Popular Stabilizers and Their Applications

Popular stabilizers such as calcium-zinc, barium-zinc, and organotin compounds are widely used in PVC to prevent degradation from heat and UV exposure, enhancing durability and longevity. Calcium-zinc stabilizers are preferred in food packaging and medical applications due to their non-toxicity, while organotin stabilizers provide superior heat stability ideal for rigid PVC products like pipes and window profiles. Barium-zinc stabilizers offer a balanced solution for flexible PVC items, including cables and flooring, by providing good processing stability and weather resistance.

Impact on Polymer Properties: Plasticizers vs Stabilizers

Plasticizers enhance polymer flexibility, softness, and elongation by reducing intermolecular forces, making materials like PVC more pliable and easier to process. Stabilizers improve polymer durability by preventing thermal and UV degradation, maintaining color and mechanical properties during exposure to heat and light. Your choice between plasticizers and stabilizers depends on whether you prioritize increased flexibility or long-term stability in the polymer product.

Safety, Environmental, and Regulatory Considerations

Plasticizers and stabilizers serve distinct roles in polymer processing, with plasticizers enhancing flexibility and stabilizers improving material durability and resistance to degradation. Safety concerns for plasticizers often focus on potential toxicity and endocrine disruption, leading to stringent regulatory limits such as those imposed by REACH and the U.S. EPA, while stabilizers are carefully evaluated for heavy metal content and long-term environmental persistence. Environmentally, biodegradable and non-toxic alternatives for both additives are increasingly prioritized to reduce ecological impact and comply with global regulations targeting sustainable and safe chemical use in plastics.

Innovations and Trends in Plasticizer and Stabilizer Development

Recent innovations in plasticizer development focus on bio-based and non-phthalate alternatives to reduce environmental impact and enhance material flexibility. Advanced stabilizers now incorporate multifunctional additives that improve thermal and UV resistance while maintaining polymer integrity. Trends emphasize sustainability, regulatory compliance, and performance optimization to meet evolving industry demands.

Choosing the Right Additive: Factors to Consider

Choosing the right additive between plasticizers and stabilizers depends on the specific requirements of the polymer application, such as flexibility, durability, and environmental exposure. Plasticizers improve polymer flexibility and workability by reducing intermolecular forces, while stabilizers enhance resistance to heat, UV radiation, and oxidative degradation, extending the material's lifespan. Consideration of polymer type, processing conditions, and end-use environment is essential to optimize performance and cost-effectiveness.

Plasticizer vs Stabilizer Infographic

libmatt.com

libmatt.com