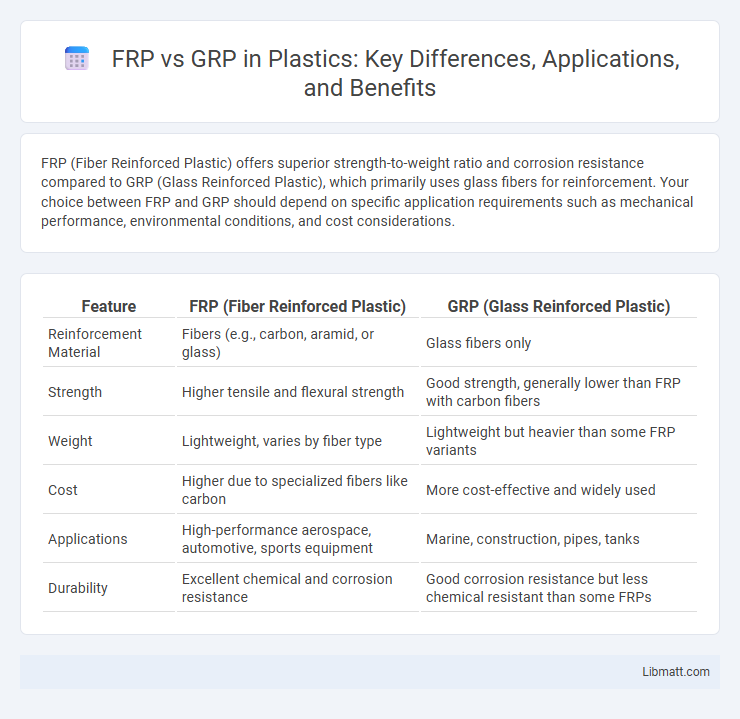

FRP (Fiber Reinforced Plastic) offers superior strength-to-weight ratio and corrosion resistance compared to GRP (Glass Reinforced Plastic), which primarily uses glass fibers for reinforcement. Your choice between FRP and GRP should depend on specific application requirements such as mechanical performance, environmental conditions, and cost considerations.

Table of Comparison

| Feature | FRP (Fiber Reinforced Plastic) | GRP (Glass Reinforced Plastic) |

|---|---|---|

| Reinforcement Material | Fibers (e.g., carbon, aramid, or glass) | Glass fibers only |

| Strength | Higher tensile and flexural strength | Good strength, generally lower than FRP with carbon fibers |

| Weight | Lightweight, varies by fiber type | Lightweight but heavier than some FRP variants |

| Cost | Higher due to specialized fibers like carbon | More cost-effective and widely used |

| Applications | High-performance aerospace, automotive, sports equipment | Marine, construction, pipes, tanks |

| Durability | Excellent chemical and corrosion resistance | Good corrosion resistance but less chemical resistant than some FRPs |

Introduction to FRP and GRP

Fiber Reinforced Polymer (FRP) is a composite material consisting of a polymer matrix reinforced with fibers such as glass, carbon, or aramid, known for its high strength-to-weight ratio and corrosion resistance. Glass Reinforced Polymer (GRP), a subset of FRP, specifically uses glass fibers as the reinforcing element, offering excellent durability and electrical insulation properties. Both materials are widely employed in construction, automotive, and aerospace industries for their lightweight and high-performance characteristics.

What is FRP?

FRP (Fiber Reinforced Polymer) is a composite material consisting of a polymer matrix reinforced with fibers such as glass, carbon, or aramid, offering superior strength-to-weight ratios compared to traditional materials. Unlike GRP (Glass Reinforced Plastic), which uses only glass fibers, FRP can incorporate various fiber types tailored for specific performance requirements in construction, automotive, and aerospace industries. Your choice between FRP and GRP depends on factors like durability, flexibility, and environmental resistance needed for the application.

What is GRP?

GRP (Glass Reinforced Plastic) is a composite material consisting of a polymer matrix reinforced with glass fibers, known for its high strength-to-weight ratio and corrosion resistance. Often used in marine, automotive, and construction industries, GRP offers excellent durability and flexibility in design. Your choice of GRP can enhance structural performance while maintaining lightweight properties compared to traditional materials.

Key Differences Between FRP and GRP

FRP (Fiber Reinforced Plastic) and GRP (Glass Reinforced Plastic) differ primarily in the type of fibers used, with FRP incorporating various fibers such as carbon, aramid, or glass, while GRP exclusively uses glass fibers for reinforcement. The mechanical properties of FRP vary significantly based on the fiber type, offering higher strength-to-weight ratios and enhanced corrosion resistance compared to GRP's generally lower cost and ease of manufacturing. FRP composites are often preferred in aerospace and high-performance automotive applications, whereas GRP is commonly utilized in construction, marine, and industrial sectors due to its economic advantages.

Material Composition Comparison

FRP (Fiber Reinforced Polymer) and GRP (Glass Reinforced Polymer) both consist of a polymer matrix reinforced with fibers, but FRP uses various fiber types such as carbon, aramid, or glass, while GRP specifically incorporates only glass fibers. The choice of fiber material significantly influences properties like strength, flexibility, and corrosion resistance, with carbon fibers in FRP offering higher tensile strength and stiffness compared to glass fibers in GRP. Understanding the distinct material compositions can help you select the ideal composite for applications requiring specific mechanical and environmental performance.

Strength and Durability Analysis

FRP (Fiber Reinforced Polymer) exhibits higher tensile strength and superior fatigue resistance compared to GRP (Glass Reinforced Polymer), making it ideal for applications requiring enhanced durability under dynamic loads. GRP, while offering excellent corrosion resistance and cost-efficiency, typically has lower impact strength and may experience matrix cracking under prolonged stress. Your choice between FRP and GRP should consider the specific strength requirements and environmental conditions to ensure optimal long-term performance.

Common Applications of FRP vs GRP

FRP (Fiber Reinforced Polymer) is commonly used in aerospace, automotive, and sporting goods due to its high strength-to-weight ratio and corrosion resistance. GRP (Glass Reinforced Polymer), a subtype of FRP, is widely applied in construction, marine, and infrastructure projects for its durability and cost-effectiveness. Your choice between FRP and GRP should consider the specific performance requirements and environmental conditions of the application.

Cost Considerations

Fiber Reinforced Plastic (FRP) generally offers a lower initial cost compared to Glass Reinforced Plastic (GRP) due to its simplified manufacturing process and availability of materials. However, GRP's superior durability and resistance to corrosion often lead to lower long-term maintenance expenses, potentially making it more cost-effective over the lifespan of your project. Evaluating both upfront costs and lifecycle expenses is essential to determine the best financial decision for your specific application.

Environmental Impact

FRP (Fiber Reinforced Plastic) and GRP (Glass Reinforced Plastic) differ significantly in environmental impact, with FRP often incorporating materials like carbon fiber that require intensive energy for production, leading to higher carbon footprints compared to GRP, which primarily uses glass fibers. GRP typically offers better recyclability and lower environmental toxicity due to its more common use of glass fibers and resins with less hazardous chemicals. Lifecycle assessments consistently show GRP as more environmentally sustainable in terms of production emissions and end-of-life disposal options, making it a preferred choice for eco-conscious applications.

Choosing the Right Material: FRP or GRP

Choosing between FRP (Fiber Reinforced Plastic) and GRP (Glass Reinforced Plastic) depends on application-specific requirements such as strength, durability, and cost-effectiveness. FRP offers superior tensile strength and resistance to corrosion, making it ideal for high-performance structural applications, while GRP provides excellent lightweight properties and cost efficiency suitable for less demanding environments. Analyzing factors like mechanical load, environmental exposure, and budget constraints ensures the optimal selection of either FRP or GRP for long-term performance.

FRP vs GRP Infographic

libmatt.com

libmatt.com