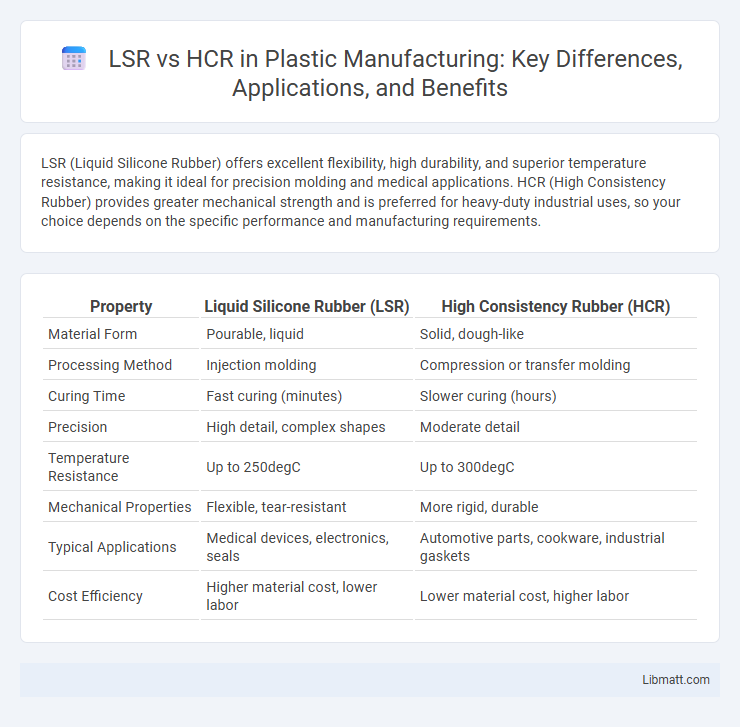

LSR (Liquid Silicone Rubber) offers excellent flexibility, high durability, and superior temperature resistance, making it ideal for precision molding and medical applications. HCR (High Consistency Rubber) provides greater mechanical strength and is preferred for heavy-duty industrial uses, so your choice depends on the specific performance and manufacturing requirements.

Table of Comparison

| Property | Liquid Silicone Rubber (LSR) | High Consistency Rubber (HCR) |

|---|---|---|

| Material Form | Pourable, liquid | Solid, dough-like |

| Processing Method | Injection molding | Compression or transfer molding |

| Curing Time | Fast curing (minutes) | Slower curing (hours) |

| Precision | High detail, complex shapes | Moderate detail |

| Temperature Resistance | Up to 250degC | Up to 300degC |

| Mechanical Properties | Flexible, tear-resistant | More rigid, durable |

| Typical Applications | Medical devices, electronics, seals | Automotive parts, cookware, industrial gaskets |

| Cost Efficiency | Higher material cost, lower labor | Lower material cost, higher labor |

Introduction to LSR and HCR

Liquid Silicone Rubber (LSR) is a two-component, platinum-cure silicone known for its flexibility, durability, and resistance to extreme temperatures, commonly used in medical, automotive, and consumer goods industries. High Consistency Rubber (HCR) is a solid silicone rubber that requires heat vulcanization and is preferred for applications needing robust mechanical properties and high-temperature resistance. Both materials offer distinct processing methods and performance characteristics tailored to specific industrial applications.

Definition of LSR (Liquid Silicone Rubber)

Liquid Silicone Rubber (LSR) is a high-purity, two-component silicone material known for its superior flexibility, biocompatibility, and resistance to extreme temperatures. Its liquid state allows for precise injection molding, making it ideal for creating complex, durable, and hygienic products in medical, automotive, and consumer goods industries. Understanding LSR's unique properties helps optimize your manufacturing process compared to High Consistency Rubber (HCR), which is solid and requires different processing techniques.

Definition of HCR (High Consistency Rubber)

High Consistency Rubber (HCR) is a type of synthetic rubber characterized by its solid or semi-solid state with a high viscosity, requiring specific mixing and processing techniques such as two-roll mills or internal mixers. Unlike Liquid Silicone Rubber (LSR), which is fluid and injection-molded, HCR is typically compression or transfer molded, offering superior mechanical strength, high temperature resistance, and excellent chemical stability. Understanding the properties of HCR allows you to select the right material for applications demanding durability and precision in harsh environments.

Key Differences Between LSR and HCR

LSR (Liquid Silicone Rubber) offers excellent flexibility, high-temperature resistance, and superior biocompatibility compared to HCR (High Consistency Rubber), which is harder and typically used for industrial sealing and insulation. Your choice depends on application needs: LSR is ideal for precision molding and medical devices, while HCR is suited for robust, heavy-duty parts requiring durability. Understanding these differences helps optimize material selection for performance and cost-efficiency.

Advantages of LSR

Liquid Silicone Rubber (LSR) offers superior flexibility, excellent thermal stability, and exceptional resistance to extreme temperatures compared to High Consistency Rubber (HCR). Its fast curing process and precision molding capabilities result in higher productivity and consistent part quality for your manufacturing needs. LSR's biocompatibility and exceptional durability make it ideal for medical, automotive, and consumer product applications.

Advantages of HCR

HCR (High Consistency Recycling) offers improved material quality by significantly reducing contaminants and maintaining fiber length compared to LSR (Low Consistency Recycling). The process enhances paper strength and brightness, leading to higher-grade recycled paper products. HCR also increases the yield and efficiency in recycling operations, making it a preferred choice for premium paper manufacturing.

Typical Applications of LSR

Liquid Silicone Rubber (LSR) is widely used in medical devices, automotive components, and consumer electronics due to its superior flexibility and biocompatibility. Its outstanding resistance to extreme temperatures and chemicals makes it ideal for sealing, gasketing, and molding complex shapes with tight tolerances. Your products benefit from LSR's rapid curing process and excellent durability, ensuring high-performance applications in critical industries.

Typical Applications of HCR

HCR (High-Consistency Regime) is commonly used in applications such as advanced sludge dewatering, paper recycling, and the production of high-quality fiber suspensions where precise control over fiber consistency is crucial. This method efficiently handles thicker pulp mixtures, improving water removal and process stability in industrial settings. Your manufacturing processes can benefit from HCR by enhancing product strength and reducing energy consumption compared to low-consistency systems like LSR (Low-Consistency Regime).

Factors to Consider When Choosing Between LSR and HCR

Choosing between Liquid Silicone Rubber (LSR) and High Consistency Rubber (HCR) depends on factors such as production volume, application requirements, and material properties. LSR is ideal for high-precision molding with faster cycle times and superior clarity, while HCR offers better mechanical strength and is suited for traditional compression or transfer molding processes. Your decision should also consider cost efficiency, desired flexibility, and thermal stability specific to your product needs.

Future Trends in Silicone Rubber Technologies

Future trends in silicone rubber technologies emphasize the integration of Liquid Silicone Rubber (LSR) and High Consistency Rubber (HCR) to enhance performance and manufacturing efficiency. Innovations target improved thermal stability, elasticity, and biocompatibility, with LSR favored for precision molding and HCR for custom extrusion applications. Advances in filler materials and curing processes are driving the development of silicone rubber compounds with higher durability and sustainability for automotive, medical, and electronics industries.

LSR vs HCR Infographic

libmatt.com

libmatt.com