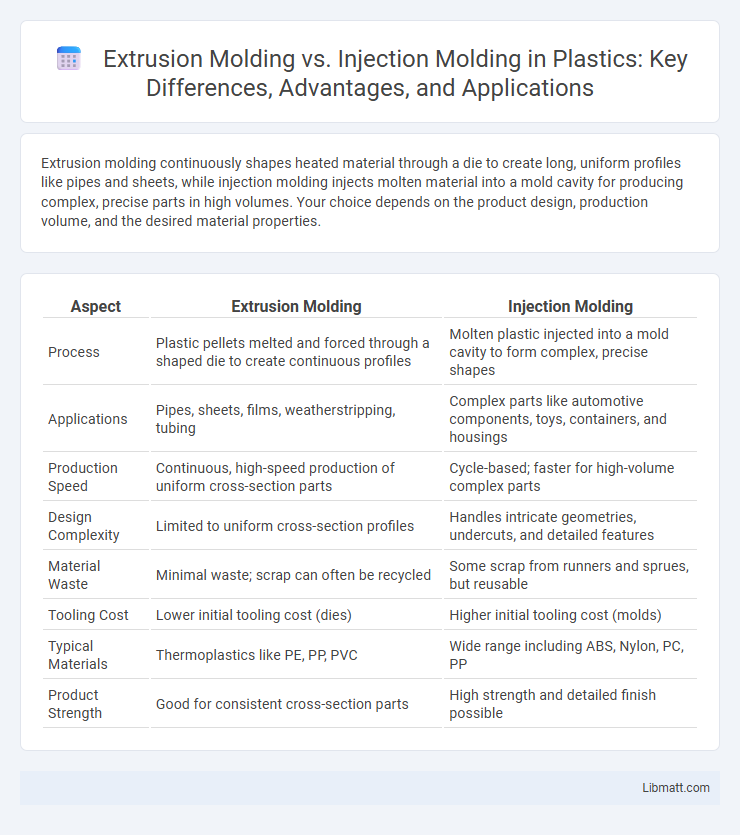

Extrusion molding continuously shapes heated material through a die to create long, uniform profiles like pipes and sheets, while injection molding injects molten material into a mold cavity for producing complex, precise parts in high volumes. Your choice depends on the product design, production volume, and the desired material properties.

Table of Comparison

| Aspect | Extrusion Molding | Injection Molding |

|---|---|---|

| Process | Plastic pellets melted and forced through a shaped die to create continuous profiles | Molten plastic injected into a mold cavity to form complex, precise shapes |

| Applications | Pipes, sheets, films, weatherstripping, tubing | Complex parts like automotive components, toys, containers, and housings |

| Production Speed | Continuous, high-speed production of uniform cross-section parts | Cycle-based; faster for high-volume complex parts |

| Design Complexity | Limited to uniform cross-section profiles | Handles intricate geometries, undercuts, and detailed features |

| Material Waste | Minimal waste; scrap can often be recycled | Some scrap from runners and sprues, but reusable |

| Tooling Cost | Lower initial tooling cost (dies) | Higher initial tooling cost (molds) |

| Typical Materials | Thermoplastics like PE, PP, PVC | Wide range including ABS, Nylon, PC, PP |

| Product Strength | Good for consistent cross-section parts | High strength and detailed finish possible |

Introduction to Extrusion and Injection Molding

Extrusion molding continuously shapes molten material by forcing it through a die, creating long, consistent profiles like pipes and sheets, while injection molding injects molten material into a mold cavity to produce precise, complex parts with detailed features. Both processes use thermoplastics and thermosets but differ in production speed, design flexibility, and material waste. Understanding these distinctions helps you select the best technique for products ranging from packaging materials to intricate automotive components.

Overview of Extrusion Molding

Extrusion molding is a continuous manufacturing process where molten material, typically plastic or metal, is forced through a shaped die to create long, uniform profiles such as pipes, sheets, and films. This method offers high production efficiency and is ideal for creating consistent cross-sectional shapes with excellent surface finish. Unlike injection molding, extrusion is suited for producing long lengths rather than complex, three-dimensional parts.

Overview of Injection Molding

Injection molding is a manufacturing process where molten plastic is injected into a mold cavity to create precise, complex shapes with high repeatability. It offers rapid production rates and excellent surface finishes, making it ideal for mass production of plastic parts such as automotive components, consumer goods, and medical devices. Your choice of injection molding ensures consistent quality and efficient material usage compared to extrusion molding, which typically produces continuous profiles rather than detailed, three-dimensional objects.

Key Differences Between Extrusion and Injection Molding

Extrusion molding continuously produces long objects with a uniform cross-section by forcing molten material through a shaped die, ideal for pipes and sheets. Injection molding injects molten material into a mold cavity to create complex, precise parts in high volumes, commonly used for automotive and consumer goods. The main differences lie in processing speed, product complexity, and typical applications, with extrusion suited for continuous profiles and injection molding for intricate, discrete components.

Materials Used in Extrusion vs Injection Molding

Extrusion molding primarily utilizes thermoplastic polymers such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC) due to their excellent flow and continuous processing capabilities. Injection molding accommodates a wider range of materials, including thermoplastics like acrylonitrile butadiene styrene (ABS), polystyrene (PS), and engineering grades such as nylon (PA) and polycarbonate (PC), favored for their precision and complex part formation. The choice of material in injection molding often depends on the required mechanical properties and detail of the finished product, whereas extrusion focuses on continuous profiles and tubes.

Advantages of Extrusion Molding

Extrusion molding offers continuous production capabilities, making it ideal for manufacturing long, uniform profiles such as pipes, tubes, and sheets with consistent cross-sections. It provides excellent material adaptability, allowing for the use of a wide range of thermoplastics and elastomers, which enhances product versatility. The process typically results in lower material waste and reduced production costs compared to injection molding, supporting efficient large-scale manufacturing.

Advantages of Injection Molding

Injection molding offers precise control over product dimensions and allows for the creation of complex geometries with tight tolerances, making it ideal for high-volume production runs. The process supports a wide range of thermoplastic and thermosetting materials, enabling versatile applications across automotive, medical, and consumer goods industries. High repeatability and automation capabilities reduce labor costs and improve efficiency compared to extrusion molding.

Common Applications of Each Process

Extrusion molding is commonly used for producing continuous profiles such as pipes, tubing, and weather stripping, ideal for applications requiring uniform cross-sections and long lengths. Injection molding is favored for manufacturing complex, high-precision components like automotive parts, medical devices, and consumer electronics enclosures due to its ability to produce detailed shapes with tight tolerances. Both processes serve distinct industries based on product design requirements, material properties, and production volumes.

Cost Comparison: Extrusion vs Injection Molding

Extrusion molding typically incurs lower upfront costs due to simpler machinery and continuous production processes, making it cost-effective for high-volume, uniform shapes like pipes and profiles. Injection molding involves higher initial investment in complex molds and machines but offers greater precision and versatility, justifying costs for detailed, high-quantity parts such as automotive components or consumer goods. Understanding these cost differences helps you select the appropriate method for efficiency and budget optimization in manufacturing projects.

Choosing the Right Molding Process for Your Project

Extrusion molding excels in producing continuous profiles with uniform cross-sections, making it ideal for pipes, tubing, and sheets, while injection molding offers precise detail and complex geometries suited for high-volume production of parts like automotive components and consumer goods. Key factors in choosing between extrusion and injection molding include the complexity of the design, production volume, material type, and surface finish requirements. Understanding these parameters ensures optimal manufacturing efficiency, cost-effectiveness, and product quality tailored to specific project needs.

Extrusion molding vs injection molding Infographic

libmatt.com

libmatt.com