Tacticity refers to the regularity of stereochemical arrangement of polymer chains, influencing properties such as crystallinity and melting point, while atacticity denotes a random, irregular arrangement leading to amorphous and flexible materials. Understanding the difference between tacticity and atacticity helps you tailor polymer characteristics for specific applications, such as enhancing strength or elasticity.

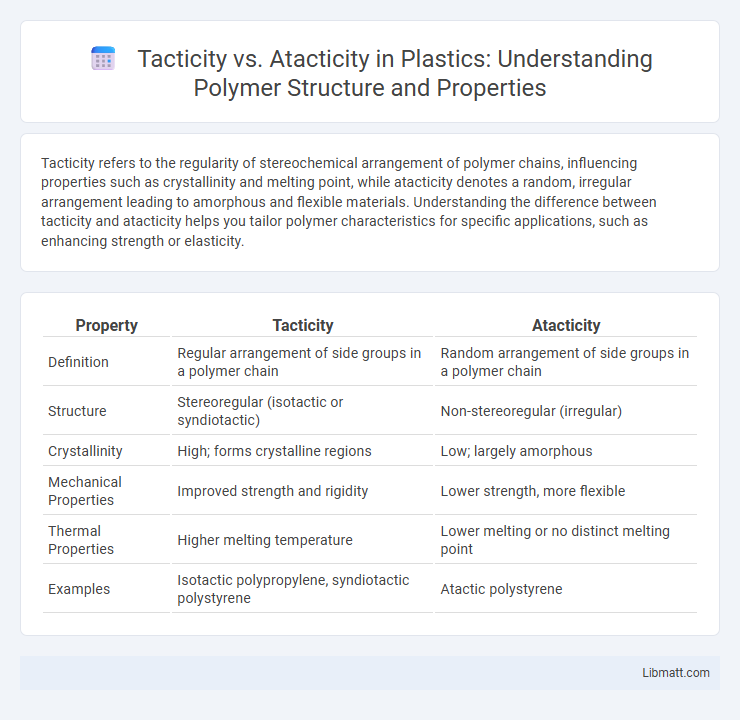

Table of Comparison

| Property | Tacticity | Atacticity |

|---|---|---|

| Definition | Regular arrangement of side groups in a polymer chain | Random arrangement of side groups in a polymer chain |

| Structure | Stereoregular (isotactic or syndiotactic) | Non-stereoregular (irregular) |

| Crystallinity | High; forms crystalline regions | Low; largely amorphous |

| Mechanical Properties | Improved strength and rigidity | Lower strength, more flexible |

| Thermal Properties | Higher melting temperature | Lower melting or no distinct melting point |

| Examples | Isotactic polypropylene, syndiotactic polystyrene | Atactic polystyrene |

Understanding Tacticity and Atacticity

Tacticity refers to the stereoregularity of polymer chains, describing the spatial arrangement of side groups along the polymer backbone, which influences crystallinity and mechanical properties. Isotactic polymers have all side groups aligned on the same side, syndiotactic polymers alternate sides, while atactic polymers exhibit random side group placement, resulting in amorphous, less rigid materials. Understanding tacticity is crucial for tailoring polymer behavior in applications such as packaging, automotive parts, and biomedical devices.

Molecular Structure Differences

Tacticity refers to the regular, repeating stereochemical arrangement of polymer chains where substituent groups are consistently positioned, forming isotactic or syndiotactic sequences. Atactic polymers lack this order, with substituent groups arranged randomly along the polymer backbone, resulting in an amorphous molecular structure. Your understanding of these differing molecular arrangements is crucial for predicting polymer properties such as crystallinity and melting behavior.

Influence on Polymer Properties

Tacticity significantly influences polymer properties by dictating the arrangement of side groups along the polymer chain, leading to variations in crystallinity, melting point, and mechanical strength. Isotactic polymers with high regularity exhibit greater crystallinity and tensile strength compared to atactic polymers, which are amorphous and possess lower melting points and reduced rigidity. The difference in tacticity directly affects thermal resistance, solubility, and processing behavior of polymers in applications like packaging, automotive parts, and medical devices.

Types of Tacticity in Polymers

Tacticity in polymers refers to the stereochemical arrangement of pendant groups along the polymer chain, with three primary types: isotactic, syndiotactic, and atactic. Isotactic polymers have all pendant groups aligned on the same side, leading to high crystallinity and melting points, while syndiotactic polymers exhibit alternating pendant groups, resulting in unique mechanical properties and enhanced solubility. Atactic polymers display random pendant group orientation, causing amorphous structures with lower density and reduced crystallinity compared to their tactic counterparts.

Atacticity: Characteristics and Examples

Atacticity refers to the irregular arrangement of side groups along a polymer chain, resulting in a lack of stereoregularity and often amorphous material properties. This characteristic leads to polymers with lower crystallinity and reduced melting points compared to their isotactic or syndiotactic counterparts. Examples of atactic polymers include atactic polypropylene and atactic polystyrene, which are commonly used in applications requiring flexibility and clarity due to their amorphous nature.

Analytical Techniques for Determining Tacticity

Nuclear Magnetic Resonance (NMR) spectroscopy is a primary analytical technique for determining polymer tacticity, revealing the stereochemical arrangement of monomer units by analyzing splitting patterns and chemical shifts. X-ray diffraction offers detailed insights into crystalline vs amorphous regions, which correlate with isotactic or atactic polymer structures, respectively. Your selection of analytical methods depends on the polymer type and required resolution to accurately characterize tacticity and optimize material properties.

Impact on Mechanical Strength

Tacticity significantly affects the mechanical strength of polymers, with isotactic polymers displaying high crystallinity that enhances tensile strength and rigidity. Atactic polymers, due to their irregular molecular arrangement, exhibit lower crystallinity and reduced mechanical strength, resulting in softer and more flexible materials. Understanding your polymer's tacticity helps optimize material performance for specific applications requiring targeted mechanical properties.

Industrial Applications and Relevance

Tacticity significantly influences the physical properties of polymers, making isotactic and syndiotactic polymers highly desirable in industrial applications such as packaging, automotive parts, and medical devices due to their enhanced crystallinity and mechanical strength. Atactic polymers, with their irregular molecular arrangement, are generally amorphous and find use in applications requiring flexibility and clarity, like adhesives, coatings, and sealants. Understanding tacticity enables your selection of the right polymer type to optimize performance and durability in specific industrial contexts.

Synthesis Methods Affecting Tacticity

Polymer tacticity, defined by the spatial arrangement of side groups, is highly influenced by synthesis methods like Ziegler-Natta and metallocene catalysis. These catalysts control the stereochemistry of polymer chains, producing isotactic, syndiotactic, or atactic configurations that determine material properties such as crystallinity and melting point. Your choice of polymerization technique directly affects the tacticity, enabling tailored mechanical strength and thermal behavior.

Future Trends in Tacticity Research

Future trends in tacticity research emphasize advanced polymer design for enhanced material properties such as strength, thermal stability, and biodegradability. Innovations in stereochemical control techniques leverage machine learning and precise catalyst development to tailor tacticity at the molecular level, driving applications in sustainable plastics and medical devices. Emerging analytical methods enable real-time monitoring of tacticity during polymerization, accelerating the discovery of novel functional polymers with customized microstructures.

Tacticity vs Atacticity Infographic

libmatt.com

libmatt.com