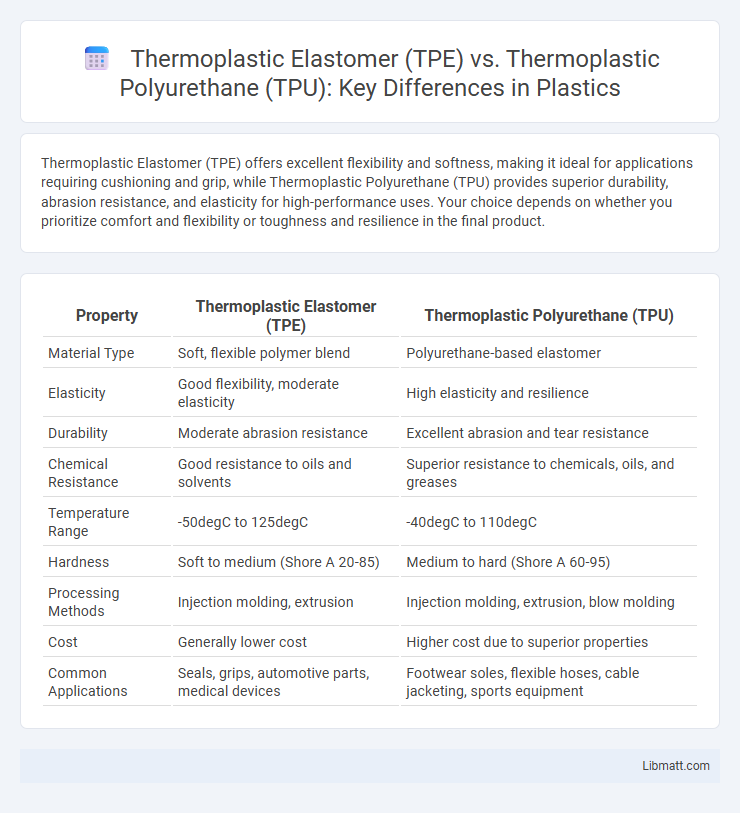

Thermoplastic Elastomer (TPE) offers excellent flexibility and softness, making it ideal for applications requiring cushioning and grip, while Thermoplastic Polyurethane (TPU) provides superior durability, abrasion resistance, and elasticity for high-performance uses. Your choice depends on whether you prioritize comfort and flexibility or toughness and resilience in the final product.

Table of Comparison

| Property | Thermoplastic Elastomer (TPE) | Thermoplastic Polyurethane (TPU) |

|---|---|---|

| Material Type | Soft, flexible polymer blend | Polyurethane-based elastomer |

| Elasticity | Good flexibility, moderate elasticity | High elasticity and resilience |

| Durability | Moderate abrasion resistance | Excellent abrasion and tear resistance |

| Chemical Resistance | Good resistance to oils and solvents | Superior resistance to chemicals, oils, and greases |

| Temperature Range | -50degC to 125degC | -40degC to 110degC |

| Hardness | Soft to medium (Shore A 20-85) | Medium to hard (Shore A 60-95) |

| Processing Methods | Injection molding, extrusion | Injection molding, extrusion, blow molding |

| Cost | Generally lower cost | Higher cost due to superior properties |

| Common Applications | Seals, grips, automotive parts, medical devices | Footwear soles, flexible hoses, cable jacketing, sports equipment |

Introduction to Thermoplastic Elastomer (TPE) and TPU

Thermoplastic Elastomers (TPE) are a class of polymers combining the elastic properties of rubber with the recyclability and processing advantages of thermoplastics, offering flexibility, durability, and ease of molding. Thermoplastic Polyurethane (TPU), a specific type of TPE, is known for its exceptional abrasion resistance, high tensile strength, and elasticity, making it ideal for applications requiring toughness and flexibility. Understanding the differences between TPE and TPU can help you select the best material based on your product's mechanical requirements and environmental exposure.

Chemical Composition and Structure

Thermoplastic Elastomers (TPE) consist of a blend of polymers, typically combining hard thermoplastic segments with soft elastomeric segments, creating a versatile material with both elasticity and thermoplastic processability. Thermoplastic Polyurethane (TPU), a subtype of TPE, features a segmented block copolymer composed of alternating soft polyol segments and hard urethane segments, providing distinct mechanical strength and abrasion resistance. This chemical composition and microphase-separated structure of TPU leads to superior durability and flexibility compared to general TPEs.

Key Physical and Mechanical Properties

Thermoplastic Elastomer (TPE) offers excellent flexibility, high elongation, and good impact resistance, making it suitable for applications requiring softness and elasticity. Thermoplastic Polyurethane (TPU) provides superior abrasion resistance, higher tensile strength, and better resistance to oils and chemicals, ideal for demanding environments. Your choice between TPE and TPU will depend on the required balance between elasticity and durability in your specific application.

Differences in Processing Methods

Thermoplastic Elastomer (TPE) is processed primarily through injection molding and extrusion, offering easier recyclability and faster cycle times due to its lower melting point. Thermoplastic Polyurethane (TPU) requires more precise temperature control during processing, often using injection molding or extrusion, but its higher melting point provides greater wear resistance and mechanical strength. The distinct thermal properties and processing parameters of TPE and TPU significantly impact their application suitability and manufacturing efficiency in industries such as automotive and medical devices.

Applications of TPE vs TPU

Thermoplastic Elastomers (TPE) are widely used in automotive parts, medical devices, and consumer goods due to their flexibility, softness, and ease of processing. Thermoplastic Polyurethane (TPU) excels in applications requiring high abrasion resistance, such as footwear soles, industrial belts, and protective cases. Your choice between TPE and TPU depends on the specific performance needs, such as durability versus elasticity, within your project.

Durability and Performance Comparison

Thermoplastic Elastomer (TPE) offers excellent flexibility and soft-touch properties but generally has lower abrasion resistance compared to Thermoplastic Polyurethane (TPU), making TPU more durable in high-wear applications. TPU provides superior tensile strength, impact resistance, and chemical stability, resulting in enhanced performance in demanding environments such as automotive and industrial sectors. Your choice between TPE and TPU should consider the specific durability requirements and mechanical stress your product will encounter.

Environmental Impact and Sustainability

Thermoplastic Elastomer (TPE) and Thermoplastic Polyurethane (TPU) differ significantly in environmental impact and sustainability, with TPE generally offering better recyclability and lower energy consumption during production. TPU, while providing superior durability and resistance, tends to involve more energy-intensive manufacturing processes and can be less eco-friendly due to its chemical composition. For your sustainable projects, choosing TPE could reduce environmental footprint through easier recycling and more efficient resource use.

Cost Analysis: TPE vs TPU

Thermoplastic Elastomer (TPE) generally offers a lower cost per unit compared to Thermoplastic Polyurethane (TPU), making TPE a more budget-friendly option for large-scale production. TPU typically provides superior mechanical properties and durability but at a higher price point due to its more complex manufacturing process and material composition. Your choice between TPE and TPU should consider the balance between upfront material costs and the long-term performance benefits required for your specific application.

Advantages and Disadvantages

Thermoplastic Elastomer (TPE) offers excellent flexibility, easy processing, and recyclability, making it suitable for applications requiring soft-touch and durability, but it generally has lower abrasion resistance and heat tolerance compared to Thermoplastic Polyurethane (TPU). TPU provides superior mechanical strength, abrasion and chemical resistance, and higher thermal stability, ideal for demanding environments, but it can be more expensive and less flexible than TPE. Selecting between TPE and TPU depends on specific application requirements such as flexibility, durability, and environmental resistance.

Choosing the Right Material for Your Project

Thermoplastic Elastomer (TPE) offers exceptional flexibility and softness, making it ideal for applications requiring elasticity and comfort, such as wearable devices and medical tubing. Thermoplastic Polyurethane (TPU) provides superior abrasion resistance and higher mechanical strength, suited for products exposed to mechanical stress like automotive parts and protective gear. Selecting the right material depends on balancing elasticity, durability, and environmental resistance based on specific project requirements.

Thermoplastic Elastomer (TPE) vs TPU Infographic

libmatt.com

libmatt.com