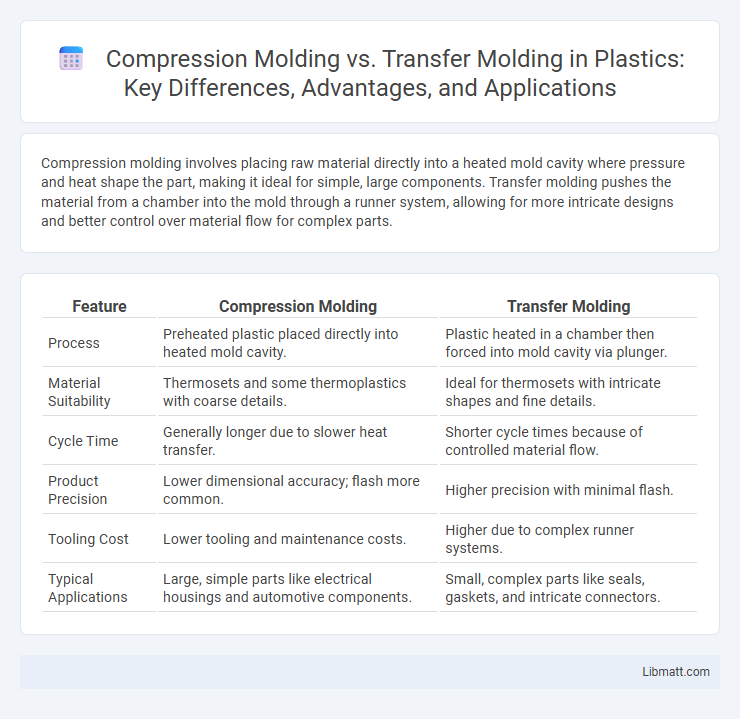

Compression molding involves placing raw material directly into a heated mold cavity where pressure and heat shape the part, making it ideal for simple, large components. Transfer molding pushes the material from a chamber into the mold through a runner system, allowing for more intricate designs and better control over material flow for complex parts.

Table of Comparison

| Feature | Compression Molding | Transfer Molding |

|---|---|---|

| Process | Preheated plastic placed directly into heated mold cavity. | Plastic heated in a chamber then forced into mold cavity via plunger. |

| Material Suitability | Thermosets and some thermoplastics with coarse details. | Ideal for thermosets with intricate shapes and fine details. |

| Cycle Time | Generally longer due to slower heat transfer. | Shorter cycle times because of controlled material flow. |

| Product Precision | Lower dimensional accuracy; flash more common. | Higher precision with minimal flash. |

| Tooling Cost | Lower tooling and maintenance costs. | Higher due to complex runner systems. |

| Typical Applications | Large, simple parts like electrical housings and automotive components. | Small, complex parts like seals, gaskets, and intricate connectors. |

Introduction to Compression and Transfer Molding

Compression molding involves placing a pre-measured amount of material directly into a heated mold cavity, where pressure and heat shape it into the desired form, making it ideal for large, simple parts with high strength requirements. Transfer molding uses a pot or chamber to first heat the material before forcing it into a closed mold through a sprue, allowing for more intricate designs and better control over material flow. Both processes are widely used for polymer composites and thermosetting plastics, with transfer molding offering improved precision in complex geometries compared to the straightforward approach of compression molding.

Overview of Compression Molding

Compression molding is a manufacturing process where pre-measured polymer material is placed directly into a heated mold cavity, and then pressure is applied to shape the part as the material cures. This technique is widely used for producing large, high-strength thermoset components with complex geometries and excellent surface finishes. It offers advantages such as low tooling cost, reduced material waste, and suitability for high-volume production runs in industries like automotive and electrical.

Overview of Transfer Molding

Transfer molding is a precise manufacturing process that injects preheated resin into a closed mold cavity, offering better control over material flow and reducing voids compared to compression molding. It is ideal for complex shapes and inserts, producing high-quality, consistent parts with minimal flash and waste. Your production benefits from enhanced dimensional accuracy and improved mechanical properties due to the controlled pressure and temperature during molding.

Key Differences Between Compression and Transfer Molding

Compression molding involves placing a pre-measured amount of raw material into an open mold cavity, then applying heat and pressure to shape the part, while transfer molding forces the material from a pot through sprues into a closed mold. Transfer molding offers better control over intricate shapes, fine details, and thin-walled parts due to the material being injected under pressure into the mold, contrasting with compression molding's simpler and often less precise process. Compression molding is typically more cost-effective and suitable for large, relatively simple components, whereas transfer molding excels in producing complex, high-strength parts with enhanced dimensional accuracy.

Material Compatibility and Selection

Compression molding excels with thermosetting polymers and composites, allowing efficient shaping of materials like epoxy, phenolic, and silicone rubber with minimal waste. Transfer molding offers better control for intricate parts and is compatible with filled thermosets, such as fiberglass-reinforced resins, enabling superior flow into detailed molds. Your choice depends on the complexity and type of materials, with compression molding favoring simpler shapes and transfer molding suited for higher precision and filled compounds.

Process Steps and Cycle Times

Compression molding involves placing a preheated polymer charge into an open, heated mold cavity, followed by closing the mold to apply pressure and shape the material; cycle times can range from 30 seconds to several minutes depending on part complexity. Transfer molding starts with placing resin in a pot where pressure forces the material into a heated mold through small channels, enabling better control and reduced voids, with typical cycle times shorter than compression molding, often between 20 to 60 seconds. Your choice of process depends on production speed requirements and part intricacy, as transfer molding typically offers faster cycle times and more precise molding of intricate designs.

Typical Applications of Each Method

Compression molding is commonly used for manufacturing large, intricate automotive parts, electrical components, and household appliances due to its efficiency in handling high-volume, high-strength thermoset materials. Transfer molding excels in producing complex, precision parts like seals, gaskets, and encapsulated electronics where detailed surface finish and tight tolerances are essential. Your choice between these methods depends on the complexity and specific performance requirements of the final product.

Advantages and Disadvantages

Compression molding offers advantages such as low tooling costs and suitability for large, simple parts but faces disadvantages like longer cycle times and limited precision. Transfer molding provides greater complexity and improved dimensional accuracy with faster production cycles but incurs higher tooling expenses and potential material waste. Both methods serve distinct manufacturing needs, with compression molding favored for cost-efficiency and transfer molding chosen for detailed, high-performance components.

Cost Considerations

Compression molding generally offers lower tooling and equipment costs, making it more cost-effective for high-volume production of simple parts. Transfer molding involves higher initial expenses due to complex tooling and precise control requirements but provides better dimensional accuracy and reduced material waste for intricate components. Your choice depends on balancing upfront investment against long-term production efficiency and part complexity.

Choosing the Right Molding Process

Selecting the appropriate molding process depends on factors such as material type, production volume, and part complexity. Compression molding is ideal for high-strength thermosetting polymers and large, simple parts, offering cost-effective tooling and high durability. Transfer molding suits intricate designs with fine details and thin walls, providing better dimensional control and reduced material waste for moderate production runs.

Compression Molding vs Transfer Molding Infographic

libmatt.com

libmatt.com