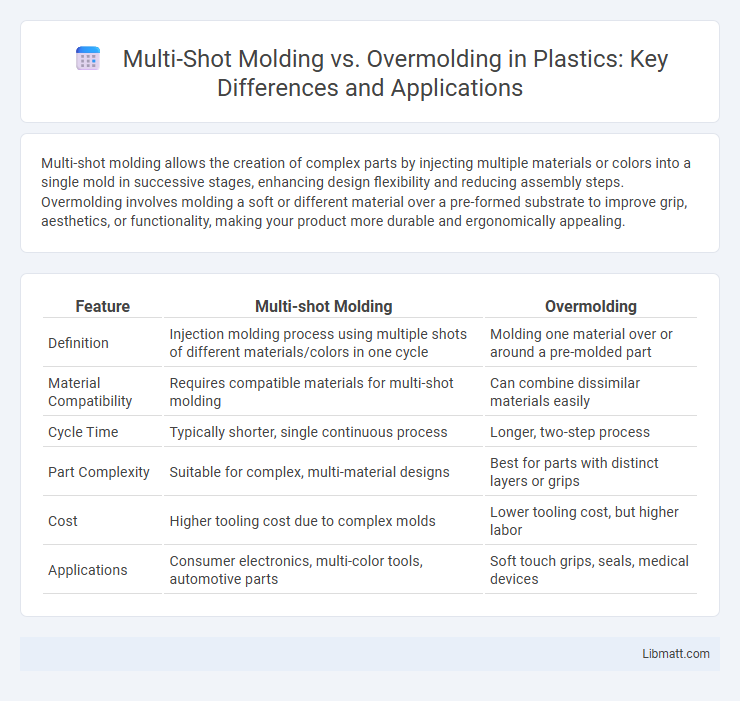

Multi-shot molding allows the creation of complex parts by injecting multiple materials or colors into a single mold in successive stages, enhancing design flexibility and reducing assembly steps. Overmolding involves molding a soft or different material over a pre-formed substrate to improve grip, aesthetics, or functionality, making your product more durable and ergonomically appealing.

Table of Comparison

| Feature | Multi-shot Molding | Overmolding |

|---|---|---|

| Definition | Injection molding process using multiple shots of different materials/colors in one cycle | Molding one material over or around a pre-molded part |

| Material Compatibility | Requires compatible materials for multi-shot molding | Can combine dissimilar materials easily |

| Cycle Time | Typically shorter, single continuous process | Longer, two-step process |

| Part Complexity | Suitable for complex, multi-material designs | Best for parts with distinct layers or grips |

| Cost | Higher tooling cost due to complex molds | Lower tooling cost, but higher labor |

| Applications | Consumer electronics, multi-color tools, automotive parts | Soft touch grips, seals, medical devices |

Introduction to Multi-shot Molding and Overmolding

Multi-shot molding involves injecting multiple materials or colors into a single mold during one production cycle, enabling complex, multi-material components with strong interlayer bonding. Overmolding is a process where one material is molded over a pre-existing part, enhancing grip, aesthetics, or functionality by combining different textures or materials. Understanding these techniques allows you to select the best method for producing durable, innovative products with intricate designs and varied material properties.

Defining Multi-shot Molding

Multi-shot molding is an advanced injection molding process that involves injecting two or more different materials or colors sequentially into a single mold to create a single part with multiple features. This technique enables the production of complex components with enhanced functionality, such as integrated grips or seals, by bonding different materials in one molding cycle. Compared to overmolding, which typically involves molding a secondary material over a preformed substrate, multi-shot molding integrates multiple materials simultaneously for seamless part consolidation and improved manufacturing efficiency.

Understanding Overmolding

Overmolding involves molding a soft material over a rigid substrate to enhance functionality, improve grip, or add seals and insulation in a single, integrated component. This process allows for complex designs with distinct material properties, optimizing part performance and aesthetic appeal. Unlike multi-shot molding, which layers different materials sequentially within the same mold, overmolding typically uses a secondary molding step to apply the overmold onto a preformed base part.

Key Differences Between Multi-shot Molding and Overmolding

Multi-shot molding involves injecting multiple materials or colors into a single mold during one cycle, producing complex parts with integrated features and enhanced aesthetics. Overmolding adds a second material onto a preformed substrate, improving grip, functionality, or protection by bonding layers. Your choice depends on factors like design complexity, material compatibility, and production efficiency.

Material Compatibility in Each Process

Multi-shot molding allows for seamless integration of multiple thermoplastic materials in a single molding cycle, enabling precise control over material placement and optimizing part functionality. Overmolding is typically used to combine dissimilar materials such as rigid plastics with elastomers, improving grip, sealing, or aesthetic properties through a two-step process. Material compatibility in multi-shot molding requires matching melting points and adhesion properties, whereas overmolding depends on surface preparation and chemistry to ensure proper bonding between substrate and overmold layers.

Typical Applications for Multi-shot Molding

Multi-shot molding is widely used in applications requiring parts with multiple material properties or colors, such as automotive components, medical devices, and consumer electronics. This process allows for precise integration of soft-touch grips with rigid plastic housings, enhancing functionality and aesthetics. Your production benefits from reduced assembly time and improved product durability through the seamless bonding of dissimilar materials in a single molding cycle.

Common Uses of Overmolding

Overmolding is commonly used in industries requiring enhanced grip, comfort, and aesthetics, such as consumer electronics, automotive components, and medical devices. It involves molding a soft or flexible material over a rigid substrate, improving ergonomics and protective properties. Your products benefit from increased durability and design versatility through overmolding applications.

Advantages and Disadvantages of Both Methods

Multi-shot molding offers the advantage of producing complex, multi-material components in a single process, improving production efficiency and reducing assembly costs, but it requires specialized machinery and higher initial investment. Overmolding enables enhanced functionality and design flexibility by molding one material over another, making it suitable for prototyping and small batches; however, it involves longer cycle times and potential adhesion issues between layers. Your choice between these methods depends on factors like production volume, part complexity, and cost constraints.

Cost Considerations: Multi-shot Molding vs Overmolding

Multi-shot molding generally incurs higher initial tooling costs due to the complexity of molds designed for multiple materials or colors, but it reduces assembly time and labor expenses by integrating processes. Overmolding typically has lower upfront tooling expenses since it uses separate molds for the substrate and overmold, but it may involve additional labor and assembly costs. Evaluating the balance between tooling investments and production efficiency is crucial for selecting the most cost-effective technique based on volume and product complexity.

Choosing the Right Process for Your Project

Selecting the ideal molding process depends on your project's complexity, material requirements, and production volume. Multi-shot molding offers precise integration of multiple materials in a single cycle, ideal for complex designs demanding high efficiency. Overmolding excels when you need a secondary material applied over a pre-molded substrate, providing enhanced grip, sealing, or aesthetics with flexible customization options.

Multi-shot Molding vs Overmolding Infographic

libmatt.com

libmatt.com