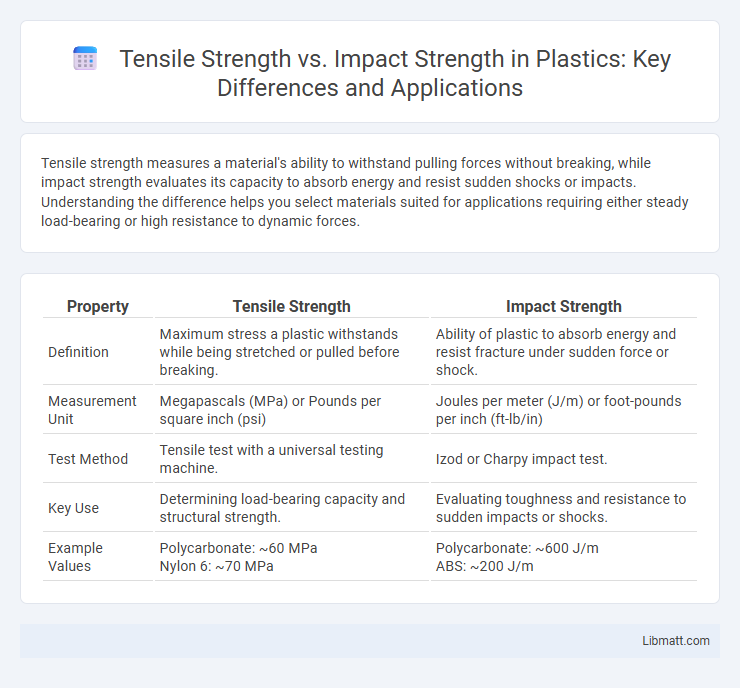

Tensile strength measures a material's ability to withstand pulling forces without breaking, while impact strength evaluates its capacity to absorb energy and resist sudden shocks or impacts. Understanding the difference helps you select materials suited for applications requiring either steady load-bearing or high resistance to dynamic forces.

Table of Comparison

| Property | Tensile Strength | Impact Strength |

|---|---|---|

| Definition | Maximum stress a plastic withstands while being stretched or pulled before breaking. | Ability of plastic to absorb energy and resist fracture under sudden force or shock. |

| Measurement Unit | Megapascals (MPa) or Pounds per square inch (psi) | Joules per meter (J/m) or foot-pounds per inch (ft-lb/in) |

| Test Method | Tensile test with a universal testing machine. | Izod or Charpy impact test. |

| Key Use | Determining load-bearing capacity and structural strength. | Evaluating toughness and resistance to sudden impacts or shocks. |

| Example Values | Polycarbonate: ~60 MPa Nylon 6: ~70 MPa |

Polycarbonate: ~600 J/m ABS: ~200 J/m |

Understanding Tensile Strength

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before breaking, providing critical insight into its durability under tension. Impact strength assesses a material's ability to absorb energy and resist sudden forces or shocks, highlighting its toughness during rapid loading. Understanding tensile strength helps you select materials that maintain structural integrity under continuous stress, crucial for applications requiring resistance to elongation and rupture.

Exploring Impact Strength

Impact strength measures a material's ability to withstand sudden forces or shocks without fracturing, which is crucial for applications involving dynamic or impact loading. Unlike tensile strength, which quantifies resistance to steady pulling forces, impact strength evaluates the energy absorbed during rapid deformation, reflecting toughness and durability under real-world conditions. Understanding impact strength helps you select materials that can endure unexpected impacts, ensuring safety and performance in structural and mechanical components.

Key Differences Between Tensile and Impact Strength

Tensile strength measures a material's resistance to breaking under tension, indicating how much load it can withstand before failure. Impact strength determines a material's ability to absorb energy and resist sudden force or shock without fracturing. Key differences include tensile strength's focus on gradual elongation and breaking point, while impact strength reflects toughness and energy absorption during rapid loading.

Importance of Tensile Strength in Materials

Tensile strength is crucial for materials used in structural applications, as it defines the maximum stress a material can withstand while being stretched or pulled before breaking. High tensile strength ensures durability and resistance to deformation under load, which is essential for construction, automotive, and aerospace industries. In contrast, impact strength measures a material's ability to absorb energy during sudden force, highlighting the necessity to balance both properties depending on application requirements.

Role of Impact Strength in Material Performance

Impact strength measures a material's ability to absorb energy and resist sudden forces, which is crucial for applications involving dynamic loads or shocks. While tensile strength indicates how much stress a material can withstand when stretched, impact strength determines its durability under rapid impact or sudden force. Understanding impact strength helps you select materials that maintain structural integrity in real-world conditions where abrupt forces occur.

Testing Methods for Tensile Strength

Tensile strength testing typically involves a universal testing machine that applies a controlled uniaxial force to a specimen until it fractures, measuring the maximum stress the material can withstand. Common methods include the ASTM D638 standard for plastics and ASTM E8 for metals, which provide precise data on elongation, yield strength, and ultimate tensile strength. Your choice of testing method depends on the material type and application requirements, ensuring accurate assessment of mechanical performance under tensile loads.

Measuring Impact Strength: Standard Practices

Measuring impact strength involves standardized tests such as the Charpy and Izod methods, which quantify a material's ability to absorb energy during a sudden force or shock. These tests use notched samples to simulate real-world fracture conditions, providing critical data on toughness and resistance to crack propagation. Accurate impact strength assessment informs material selection in applications requiring durability under dynamic loads, complementing tensile strength measurements that evaluate resistance to slow, static forces.

Factors Affecting Tensile and Impact Strength

Material composition, microstructure, and temperature significantly influence tensile and impact strength, determining how substances deform or fracture under stress. Strain rate and flaw presence also affect impact resistance, while tensile strength depends heavily on grain size and loading conditions. Understanding these factors helps you predict material performance in applications requiring both durability and toughness.

Applications Requiring High Tensile vs. Impact Strength

Applications requiring high tensile strength, such as structural beams and load-bearing components, demand materials capable of withstanding substantial pulling forces without breaking. In contrast, applications like automotive bumpers and protective gear prioritize impact strength to absorb sudden shocks and prevent fractures. Your material selection should align with whether resistance to pulling forces or capacity to endure sudden impacts is critical for performance and safety.

Choosing Materials: Balancing Tensile and Impact Strength

Selecting materials requires a precise balance between tensile strength and impact strength to ensure durability and resistance under varying stress conditions. High tensile strength materials excel in withstanding pulling forces, while high impact strength materials absorb sudden shocks without fracturing. Optimizing this balance is crucial in industries like automotive and aerospace, where components must sustain both static loads and dynamic impacts.

Tensile strength vs impact strength Infographic

libmatt.com

libmatt.com