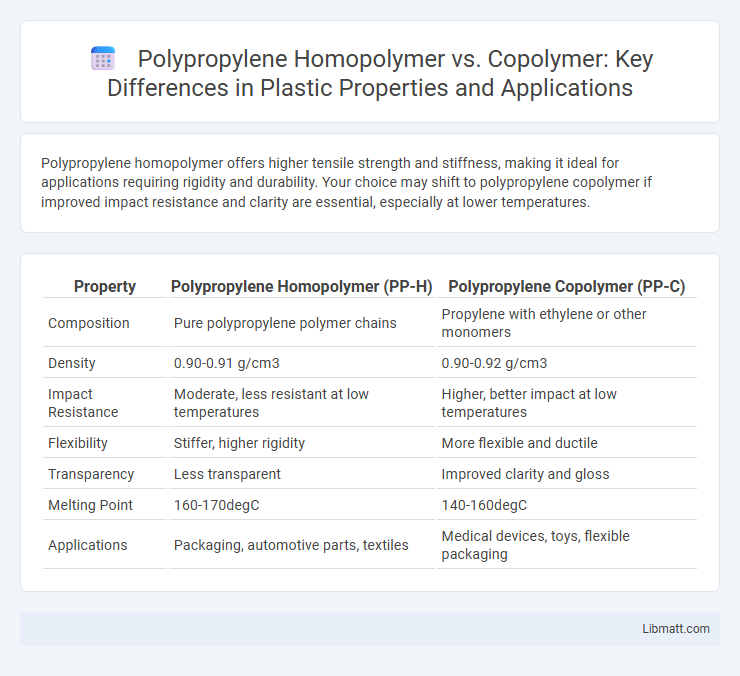

Polypropylene homopolymer offers higher tensile strength and stiffness, making it ideal for applications requiring rigidity and durability. Your choice may shift to polypropylene copolymer if improved impact resistance and clarity are essential, especially at lower temperatures.

Table of Comparison

| Property | Polypropylene Homopolymer (PP-H) | Polypropylene Copolymer (PP-C) |

|---|---|---|

| Composition | Pure polypropylene polymer chains | Propylene with ethylene or other monomers |

| Density | 0.90-0.91 g/cm3 | 0.90-0.92 g/cm3 |

| Impact Resistance | Moderate, less resistant at low temperatures | Higher, better impact at low temperatures |

| Flexibility | Stiffer, higher rigidity | More flexible and ductile |

| Transparency | Less transparent | Improved clarity and gloss |

| Melting Point | 160-170degC | 140-160degC |

| Applications | Packaging, automotive parts, textiles | Medical devices, toys, flexible packaging |

Introduction to Polypropylene: Homopolymer vs Copolymer

Polypropylene homopolymer consists of a single type of propylene monomer, offering higher tensile strength and rigidity ideal for automotive parts and packaging. Polypropylene copolymer incorporates ethylene units, enhancing impact resistance and flexibility suitable for cold temperature applications and consumer goods. Understanding these molecular differences helps optimize material selection for specific performance requirements in manufacturing.

Chemical Structure and Composition Differences

Polypropylene homopolymer consists of a uniform polymer chain made entirely of propylene monomers, resulting in a crystalline structure with high tensile strength and stiffness. In contrast, polypropylene copolymer incorporates ethylene monomers alongside propylene, introducing irregularities that enhance impact resistance and flexibility by reducing crystallinity. Understanding these chemical composition differences helps you select the appropriate polypropylene type tailored to your application's mechanical and thermal property requirements.

Manufacturing Processes Compared

Polypropylene homopolymer is produced through a polymerization process using only propylene monomers, typically employing Ziegler-Natta or metallocene catalysts for high crystallinity and stiffness. In contrast, polypropylene copolymer incorporates ethylene monomers into the polymer chain, using similar catalytic methods but resulting in a material with improved impact resistance and flexibility due to its random or block copolymer structure. The manufacturing variation between homopolymer and copolymer directly influences mechanical properties and processing parameters such as melt flow index and crystallization behavior.

Physical and Mechanical Properties

Polypropylene homopolymer exhibits higher stiffness and tensile strength due to its more crystalline structure, making it ideal for applications requiring rigidity and impact resistance. In contrast, polypropylene copolymer offers improved impact resistance and flexibility at lower temperatures because of the ethylene comonomer, which reduces crystallinity and enhances toughness. Both types have similar chemical resistance, but copolymers provide better clarity and resistance to stress cracking in dynamic mechanical environments.

Applications of Polypropylene Homopolymer

Polypropylene homopolymer is widely used in automotive parts, consumer goods, and packaging due to its high tensile strength, stiffness, and resistance to chemicals. It is ideal for manufacturing rigid containers, household appliances, and textiles where durability and thermal resistance are essential. Its superior clarity and glossy finish also make it suitable for medical devices and food packaging applications.

Applications of Polypropylene Copolymer

Polypropylene copolymer is widely used in applications requiring enhanced impact resistance and flexibility, such as automotive parts, packaging films, and medical devices. Its improved toughness at lower temperatures makes it ideal for household goods, toys, and pipes that must endure mechanical stress. Your choice of polypropylene copolymer ensures higher durability and performance in demanding environments compared to homopolymer variants.

Comparative Advantages and Disadvantages

Polypropylene homopolymer offers superior rigidity, higher tensile strength, and better chemical resistance, making it ideal for applications requiring durability and structural integrity. Polypropylene copolymer, with its enhanced impact resistance and improved low-temperature performance, is better suited for flexible packaging and automotive parts exposed to variable conditions. Your choice depends on whether strength or flexibility is prioritized, as homopolymer excels in rigidity while copolymer provides enhanced toughness and ductility.

Cost and Market Availability

Polypropylene Homopolymer generally offers lower cost and higher market availability due to its simpler polymerization process and widespread industrial use. Copolymer polypropylene, while typically more expensive, provides enhanced impact resistance and flexibility, which can justify the premium in specialized applications. Market demand favors homopolymers for cost-sensitive manufacturing, but copolymers maintain steady availability driven by sectors requiring advanced material properties.

Environmental Impact and Recyclability

Polypropylene homopolymer typically exhibits higher crystallinity, making it more rigid and easier to recycle through conventional mechanical processes, resulting in lower environmental impact due to efficient material recovery. Copolymer variants, which include ethylene segments, offer enhanced flexibility and impact resistance but pose challenges in recycling streams due to mixed polymer composition, potentially increasing environmental burden. Advanced sorting technologies and chemical recycling methods are essential to improving the sustainability profile of polypropylene copolymers by enabling more effective separation and reprocessing.

Choosing the Right Polypropylene for Your Needs

Polypropylene homopolymer offers higher strength and rigidity, making it ideal for applications requiring durability and stiffness such as automotive parts and household goods. Polypropylene copolymer provides enhanced impact resistance and flexibility, suited for cold environments and medical devices. Selecting the right polypropylene depends on the balance between mechanical properties and environmental conditions specific to your project requirements.

Polypropylene Homopolymer vs Copolymer Infographic

libmatt.com

libmatt.com