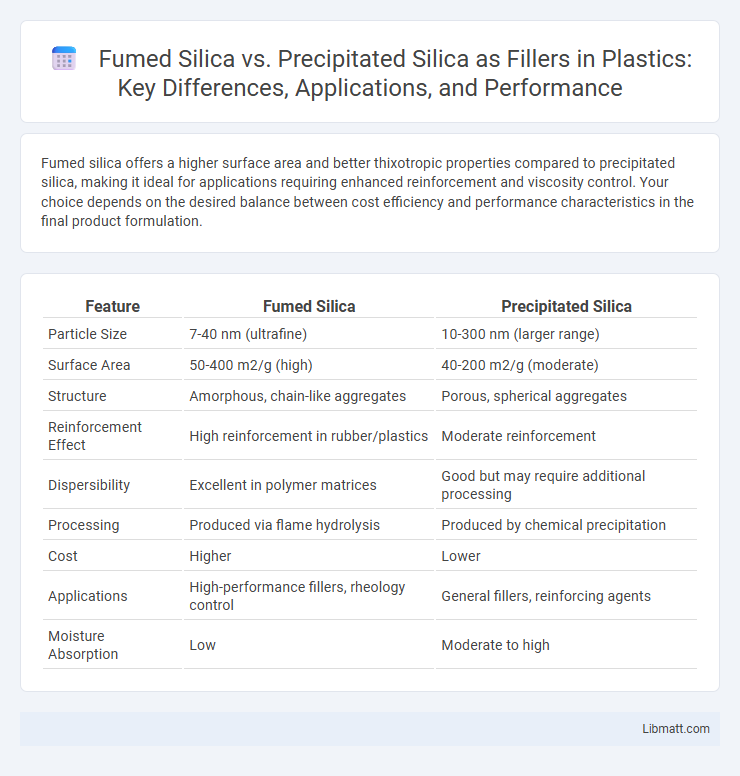

Fumed silica offers a higher surface area and better thixotropic properties compared to precipitated silica, making it ideal for applications requiring enhanced reinforcement and viscosity control. Your choice depends on the desired balance between cost efficiency and performance characteristics in the final product formulation.

Table of Comparison

| Feature | Fumed Silica | Precipitated Silica |

|---|---|---|

| Particle Size | 7-40 nm (ultrafine) | 10-300 nm (larger range) |

| Surface Area | 50-400 m2/g (high) | 40-200 m2/g (moderate) |

| Structure | Amorphous, chain-like aggregates | Porous, spherical aggregates |

| Reinforcement Effect | High reinforcement in rubber/plastics | Moderate reinforcement |

| Dispersibility | Excellent in polymer matrices | Good but may require additional processing |

| Processing | Produced via flame hydrolysis | Produced by chemical precipitation |

| Cost | Higher | Lower |

| Applications | High-performance fillers, rheology control | General fillers, reinforcing agents |

| Moisture Absorption | Low | Moderate to high |

Overview of Silica Fillers in Industrial Applications

Fumed silica and precipitated silica both serve as essential fillers in industrial applications, improving mechanical strength, viscosity, and durability in composites, adhesives, and coatings. Fumed silica, produced through flame hydrolysis, offers a higher surface area and purity, resulting in superior reinforcement and thickening properties. Precipitated silica, manufactured via wet chemical methods, provides cost-effective bulk fillers with controlled particle size and porosity, widely used in rubber, plastics, and tire manufacturing for improved wear resistance and performance.

What is Fumed Silica? Key Characteristics

Fumed silica, also known as pyrogenic silica, is a highly pure, amorphous form of silicon dioxide produced through flame hydrolysis of silicon tetrachloride. Key characteristics include a high surface area typically between 50-400 m2/g, extremely low bulk density around 50 kg/m3, and extremely small primary particle size averaging 7-40 nanometers, which contributes to its thickening and reinforcing properties in composites. Its hydrophobic or hydrophilic surface treatment options allow tailored compatibility with diverse polymers, improving mechanical strength and rheological performance in filler applications.

What is Precipitated Silica? Core Properties

Precipitated silica is a white, amorphous form of silicon dioxide produced through the controlled precipitation of sodium silicate with acid, resulting in fine, porous particles. Its core properties include high surface area, excellent dispersibility, and strong reinforcing capabilities, making it ideal as a filler in rubber, plastics, and coatings. Precipitated silica enhances mechanical strength, abrasion resistance, and viscosity control in composite materials.

Production Processes: Fumed vs Precipitated Silica

Fumed silica is produced through flame hydrolysis of silicon tetrachloride, resulting in a low-density, highly pure, and amorphous silicon dioxide with a strong three-dimensional network structure. Precipitated silica is synthesized by reacting silicate solutions with acid, creating particles with a more aggregated and less porous morphology. These distinct production methods influence their surface area, particle size, and performance characteristics used in rubber, coatings, and adhesives.

Particle Morphology and Surface Area Comparison

Fumed silica features a three-dimensional, branched chain-like morphology with primary particles averaging 7-40 nm, resulting in a high surface area typically between 50-400 m2/g, enhancing its reinforcing properties in composites. Precipitated silica consists of aggregated spherical particles around 10-200 nm with a porous structure, leading to a surface area range of 40-300 m2/g, which influences its reinforcing efficiency and dispersion in polymer matrices. The distinct particle morphology and higher surface area of fumed silica contribute to stronger filler-polymer interactions and improved mechanical performance compared to precipitated silica.

Performance Differences as Fillers in Polymers

Fumed silica exhibits higher surface area and stronger thixotropic properties compared to precipitated silica, enhancing reinforcement and viscosity control in polymer composites. Precipitated silica provides better dispersion and cost-effectiveness, making it suitable for applications requiring moderate mechanical strength and improved processing. Your choice depends on the desired balance between mechanical performance, flow behavior, and economic considerations in polymer formulations.

Rheological and Thickening Effects

Fumed silica exhibits a higher specific surface area and stronger surface energy compared to precipitated silica, resulting in superior thickening and thixotropic properties in polymer and coating formulations. Its nano-sized, chain-like structure creates a robust three-dimensional network that significantly enhances viscosity and rheological stability under shear stress. In contrast, precipitated silica, with larger particle agglomerates and lower surface activity, offers moderate thickening effects but excels in reinforcing fillers where lower viscosity impact is desired.

Impact on Mechanical Properties of End Products

Fumed silica enhances mechanical properties by providing superior reinforcement, improving tensile strength, and increasing abrasion resistance in end products due to its high surface area and fine particle size. Precipitated silica, while also acting as a reinforcement filler, typically imparts moderate improvements in stiffness and impact resistance but may lead to higher compound viscosity. Your choice between fumed silica and precipitated silica significantly influences durability, flexibility, and overall performance in rubber, plastics, and coatings applications.

Cost Considerations and Economic Viability

Fumed silica typically has a higher production cost due to its specialized manufacturing process, resulting in increased prices compared to precipitated silica, which is produced more economically through wet chemical methods. Your choice between the two should consider the balance between performance benefits offered by fumed silica, such as superior reinforcement and thixotropic properties, and the cost-efficiency of precipitated silica in large-scale applications. For budget-sensitive projects, precipitated silica often provides better economic viability without significantly compromising filler functionality.

Choosing the Right Silica Filler: Application-Based Recommendations

Fumed silica offers a high surface area and thickening properties, making it ideal for applications requiring enhanced viscosity and reinforcement in coatings, adhesives, and sealants. Precipitated silica provides better dispersion and is preferred in rubber and tire manufacturing due to its abrasion resistance and durability. Your choice between fumed and precipitated silica should depend on specific application needs such as mechanical strength, viscosity control, and processing conditions.

Fumed silica vs precipitated silica (as filler) Infographic

libmatt.com

libmatt.com