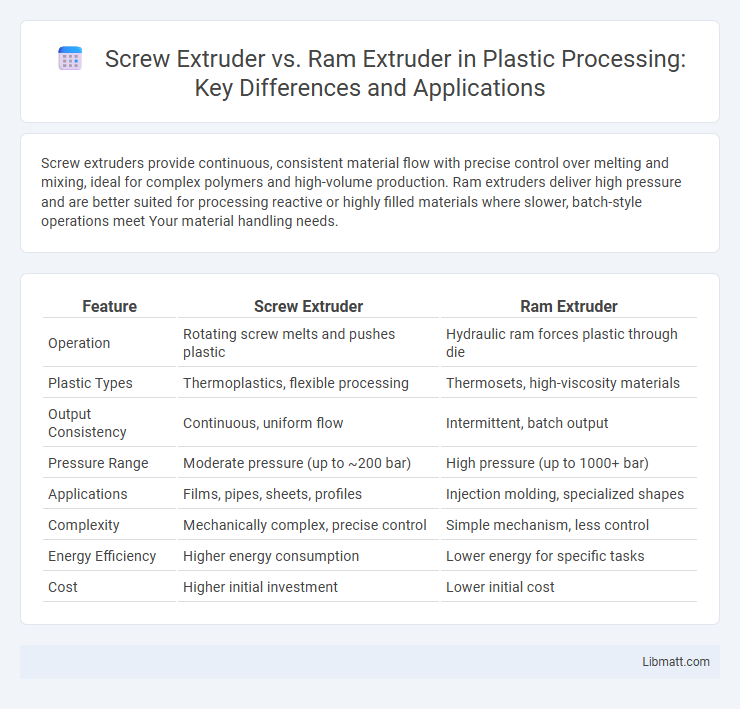

Screw extruders provide continuous, consistent material flow with precise control over melting and mixing, ideal for complex polymers and high-volume production. Ram extruders deliver high pressure and are better suited for processing reactive or highly filled materials where slower, batch-style operations meet Your material handling needs.

Table of Comparison

| Feature | Screw Extruder | Ram Extruder |

|---|---|---|

| Operation | Rotating screw melts and pushes plastic | Hydraulic ram forces plastic through die |

| Plastic Types | Thermoplastics, flexible processing | Thermosets, high-viscosity materials |

| Output Consistency | Continuous, uniform flow | Intermittent, batch output |

| Pressure Range | Moderate pressure (up to ~200 bar) | High pressure (up to 1000+ bar) |

| Applications | Films, pipes, sheets, profiles | Injection molding, specialized shapes |

| Complexity | Mechanically complex, precise control | Simple mechanism, less control |

| Energy Efficiency | Higher energy consumption | Lower energy for specific tasks |

| Cost | Higher initial investment | Lower initial cost |

Introduction to Extrusion Technologies

Screw extruders use a rotating screw to melt and convey material through a barrel, enabling continuous and precise control of temperature and pressure for consistent product quality. Ram extruders rely on a hydraulic ram to push molten material through a die, typically suited for high-pressure applications and producing dense, uniform parts. Understanding these key differences helps you choose the ideal extrusion technology for specific manufacturing needs such as polymer shaping or metal forming.

Overview of Screw Extruders

Screw extruders utilize one or more helical screws to continuously push and melt plastic materials through a heated barrel, making them ideal for high-volume production and consistent output. These machines ensure precise control over temperature, pressure, and shear, resulting in uniform melt quality suitable for complex profiles, films, and pellets. Compared to ram extruders, screw extruders offer greater versatility and efficiency in processing a wide range of thermoplastics and thermosets.

Overview of Ram Extruders

Ram extruders use a piston to push material through a die, providing precise control over pressure and flow rates ideal for high-viscosity or heat-sensitive compounds. This method excels in producing uniform pellets, sheets, or profiles with consistent density, making it suitable for specialty polymers and pharmaceutical applications. Your choice of a ram extruder can enhance product quality when processing materials that require gentle handling and precise dosing.

Key Components and Mechanisms

A screw extruder utilizes a rotating helical screw within a heated barrel to convey, compress, and melt raw material, featuring key components such as the feed hopper, screw shaft, barrel, and die. In contrast, a ram extruder operates by using a piston-like ram to push material through a heated barrel and die, emphasizing components like the ram chamber, hydraulic or mechanical ram, barrel, and die assembly. The screw extruder's continuous feeding and melting mechanism allow for precise control over material flow and temperature, while the ram extruder's batch processing design excels in handling high-viscosity materials and achieving uniform compaction.

Process Differences: Screw vs Ram Extruders

Screw extruders use a rotating screw to continuously convey, compress, and melt material through a heated barrel, enabling precise control of temperature and pressure for consistent output. Ram extruders operate by using a hydraulic or mechanical ram to push material through a die in a single, powerful stroke, ideal for highly viscous or thermally sensitive materials. Your choice between screw and ram extruders depends on the specific processing requirements, such as material viscosity, production speed, and product uniformity.

Material Compatibility and Flexibility

Screw extruders excel in material compatibility and flexibility, efficiently processing a wide range of thermoplastics, including polymers with fillers and reinforcements, due to their continuous mixing and shearing action. Ram extruders are best suited for highly viscous or low-melting-point materials like elastomers and thermosets, providing precise control over material flow and pressure but with limited adaptability to varied materials. Your choice depends on the specific requirements of material type and process versatility needed for your application.

Production Efficiency and Throughput

Screw extruders offer higher production efficiency and throughput due to their continuous operation and ability to process a wide range of materials with consistent melting and mixing. Ram extruders operate intermittently, resulting in slower cycle times and lower output, making them less suitable for large-scale production. The mechanical design of screw extruders enhances material homogeneity and reduces downtime, further optimizing throughput rates.

Quality and Consistency of Output

Screw extruders deliver superior quality and consistency of output by ensuring continuous, uniform melting and mixing of materials, resulting in homogeneous products with precise dimensional control. Ram extruders, while simpler, often produce less consistent output due to batch processing and variable pressure application, leading to potential fluctuations in material density and surface finish. Your choice of extrusion technology directly impacts product reliability, especially when high precision and consistent material properties are essential.

Typical Industrial Applications

Screw extruders are commonly used in plastic manufacturing, packaging films, and food processing industries due to their continuous operation and precise material mixing capabilities. Ram extruders find typical applications in the production of rubber products, thermoset plastics, and composite materials where high pressure and batch processing are essential. Your choice depends on the required production volume and material properties in the targeted industrial application.

Choosing the Right Extruder for Your Needs

Screw extruders provide continuous, high-volume output ideal for plastic and rubber processing, while ram extruders excel in precision and high-pressure applications such as metal or ceramics. Consider material type, production scale, and required pressure to determine the best fit; screw extruders offer superior mixing and consistent flow, whereas ram extruders deliver controlled, high-force extrusion. Selecting the right extruder depends on balancing throughput needs with material characteristics and process demands.

Screw extruder vs ram extruder Infographic

libmatt.com

libmatt.com