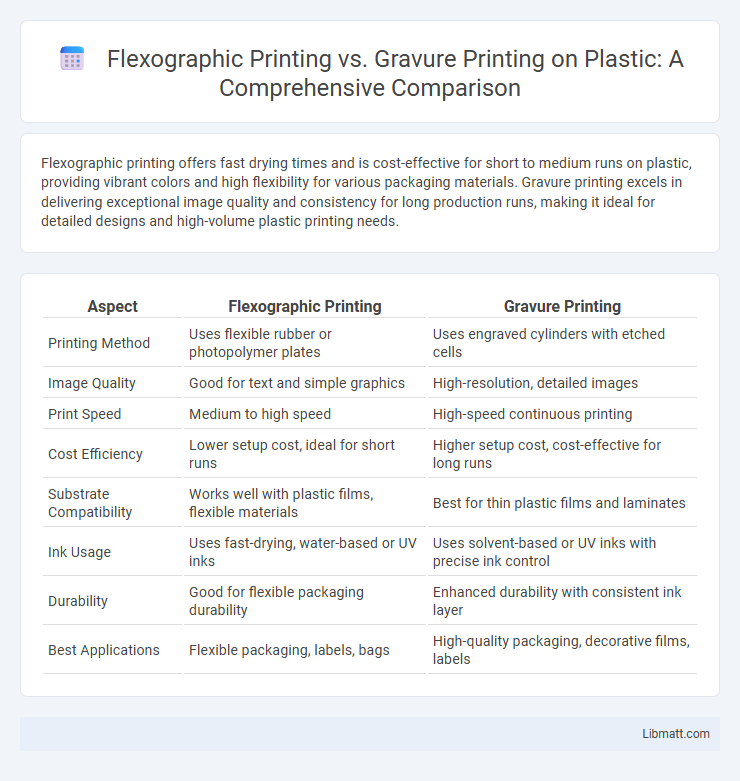

Flexographic printing offers fast drying times and is cost-effective for short to medium runs on plastic, providing vibrant colors and high flexibility for various packaging materials. Gravure printing excels in delivering exceptional image quality and consistency for long production runs, making it ideal for detailed designs and high-volume plastic printing needs.

Table of Comparison

| Aspect | Flexographic Printing | Gravure Printing |

|---|---|---|

| Printing Method | Uses flexible rubber or photopolymer plates | Uses engraved cylinders with etched cells |

| Image Quality | Good for text and simple graphics | High-resolution, detailed images |

| Print Speed | Medium to high speed | High-speed continuous printing |

| Cost Efficiency | Lower setup cost, ideal for short runs | Higher setup cost, cost-effective for long runs |

| Substrate Compatibility | Works well with plastic films, flexible materials | Best for thin plastic films and laminates |

| Ink Usage | Uses fast-drying, water-based or UV inks | Uses solvent-based or UV inks with precise ink control |

| Durability | Good for flexible packaging durability | Enhanced durability with consistent ink layer |

| Best Applications | Flexible packaging, labels, bags | High-quality packaging, decorative films, labels |

Overview of Flexographic Printing and Gravure Printing

Flexographic printing uses flexible relief plates made from rubber or photopolymer, making it ideal for high-speed production on various substrates, including plastic films, labels, and packaging materials. Gravure printing employs engraved cylinders to transfer rich, detailed images onto plastic, offering superior print quality and consistent ink distribution for long-run applications. Both methods serve the plastic industry with unique advantages: flexography excels in quick setup and cost-effectiveness, while gravure delivers precision and durability in printed designs.

Key Differences in Printing Processes

Flexographic printing uses flexible relief plates and fast-drying inks to print on plastic surfaces, ideal for short to medium runs with high-speed production. Gravure printing employs engraved cylinders and liquid inks, delivering extremely fine detail and consistent image quality suited for long runs with high-volume output. Your choice depends on the desired print quality, production speed, and run length, with flexography offering cost-effective versatility and gravure providing premium image fidelity.

Material Compatibility with Plastic Substrates

Flexographic printing excels in compatibility with a wide range of plastic substrates such as polyethylene, polypropylene, and PVC due to its flexible polymer plates that conform well to uneven surfaces. Gravure printing offers superior quality and sharpness on smooth plastic films like BOPP and PET, benefiting from engraved cylinders that control ink flow precisely. Both methods require careful ink formulation and substrate treatment to ensure optimal adhesion and durability on plastic materials.

Print Quality and Image Resolution

Flexographic printing on plastic offers versatile and cost-effective solutions with moderate print quality and image resolution, making it ideal for large runs of simple graphics and bold colors. Gravure printing excels in delivering superior print quality and high image resolution, capturing intricate details and smooth gradients due to its engraved cylinder process. When your project demands sharp, precise images with rich color depth, gravure printing provides a significant advantage over flexographic methods.

Speed and Production Efficiency

Flexographic printing on plastic offers faster setup times and quicker turnaround, making it ideal for high-speed production runs with frequent job changes. Gravure printing excels in continuous, high-volume production with superior color consistency and minimal downtime, resulting in exceptional efficiency for large-scale jobs. Your choice depends on balancing the need for rapid flexibility in flexography against the unmatched speed and quality stability of gravure in extensive runs.

Cost Comparison: Setup and Running Expenses

Flexographic printing on plastic generally offers lower setup costs due to simpler plate production and faster changeovers, making it cost-effective for short to medium runs. Gravure printing incurs higher initial setup expenses because of engraving cylinders but delivers lower running costs and superior print consistency on long production runs. Evaluating total expenses depends on print volume, with flexography favored for smaller batches and gravure optimal for large-scale, high-quality plastic packaging projects.

Flexibility in Design and Color Options

Flexographic printing offers greater flexibility in design and color options on plastic materials, allowing for quick adjustments and vibrant hues through water-based or UV inks. Gravure printing, while delivering superior image quality and consistent color reproduction, typically involves higher setup costs and is less adaptable to frequent design changes. Your choice depends on whether you prioritize design versatility or high-volume precision in plastic printing projects.

Environmental Impact and Sustainability

Flexographic printing on plastic offers lower energy consumption and reduced solvent emissions compared to gravure printing, making it a more environmentally friendly option for sustainable packaging. Gravure printing uses high amounts of ink and solvents, resulting in higher VOC emissions and greater waste generation. Sustainable practices in flexography include water-based inks and recyclable substrates, supporting eco-conscious manufacturing goals.

Typical Applications in the Plastics Industry

Flexographic printing is predominantly used for flexible packaging such as plastic films, bags, and labels due to its efficiency in high-speed runs and ability to print on a wide variety of plastic substrates. Gravure printing excels in producing high-quality, detailed images on large volumes of plastic packaging like laminates and wraps, often utilized in food packaging and decorative applications. Your choice hinges on the balance between production volume, image quality, and substrate compatibility required for your specific plastic packaging needs.

Choosing the Right Printing Method for Your Project

Flexographic printing offers cost-effective, high-speed production ideal for short to medium runs on plastic, providing vibrant colors with quick drying times. Gravure printing delivers superior image quality and fine detail, making it suitable for large-volume projects requiring consistent, high-resolution results. Evaluate your project's budget, print volume, and image complexity to choose the right printing method for your plastic packaging needs.

Flexographic Printing vs Gravure Printing on Plastic Infographic

libmatt.com

libmatt.com