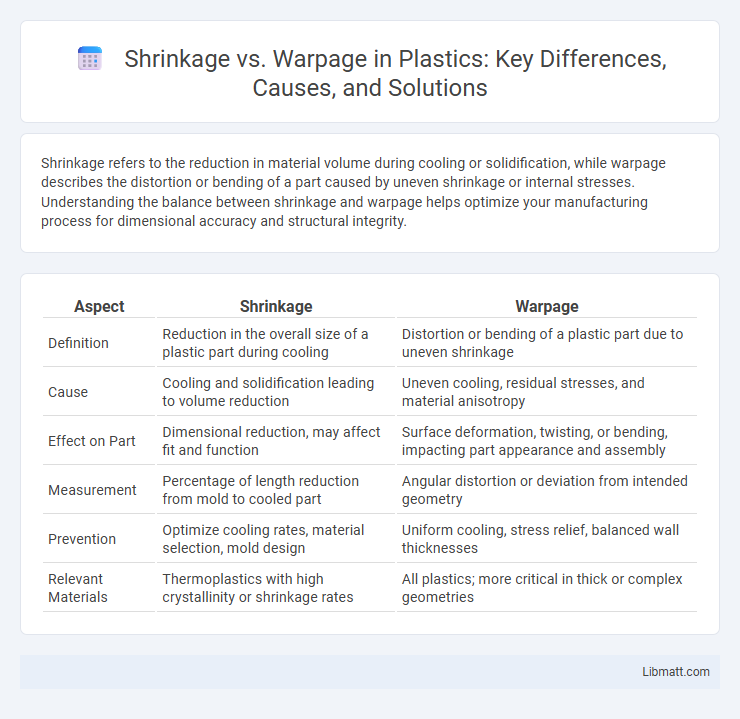

Shrinkage refers to the reduction in material volume during cooling or solidification, while warpage describes the distortion or bending of a part caused by uneven shrinkage or internal stresses. Understanding the balance between shrinkage and warpage helps optimize your manufacturing process for dimensional accuracy and structural integrity.

Table of Comparison

| Aspect | Shrinkage | Warpage |

|---|---|---|

| Definition | Reduction in the overall size of a plastic part during cooling | Distortion or bending of a plastic part due to uneven shrinkage |

| Cause | Cooling and solidification leading to volume reduction | Uneven cooling, residual stresses, and material anisotropy |

| Effect on Part | Dimensional reduction, may affect fit and function | Surface deformation, twisting, or bending, impacting part appearance and assembly |

| Measurement | Percentage of length reduction from mold to cooled part | Angular distortion or deviation from intended geometry |

| Prevention | Optimize cooling rates, material selection, mold design | Uniform cooling, stress relief, balanced wall thicknesses |

| Relevant Materials | Thermoplastics with high crystallinity or shrinkage rates | All plastics; more critical in thick or complex geometries |

Understanding Shrinkage and Warpage

Shrinkage refers to the reduction in volume or size of a material as it cools and solidifies, often causing dimensional inaccuracies in molded parts. Warpage occurs when differential shrinkage causes deformation or bending, leading to distorted shapes and compromised mechanical properties. Understanding the correlation between shrinkage rates and material behavior is crucial for optimizing mold design and processing parameters to minimize defects.

Causes of Shrinkage in Manufacturing

Shrinkage in manufacturing primarily results from the cooling and solidification of molten materials, causing a reduction in volume as the material transitions from liquid to solid. Factors such as improper mold design, uneven cooling rates, and inadequate packing pressure exacerbate shrinkage by creating voids or sink marks. Material-specific properties, including thermal expansion coefficients and resin composition, also significantly influence the degree of shrinkage experienced during production.

Factors Contributing to Warpage

Warpage in molded parts is primarily influenced by uneven cooling rates, material shrinkage, and residual stresses, which distort the part's shape after solidification. Variations in wall thickness and mold temperature also contribute significantly to warpage by causing differential contraction. The type of polymer and its thermal properties, including coefficient of thermal expansion and crystallinity, directly affect the extent of warpage in injection-molded components.

Material Selection and Its Impact

Material selection significantly influences shrinkage and warpage in manufacturing processes, with polymers such as polypropylene exhibiting higher shrinkage rates compared to ABS due to their molecular structure. Materials with low thermal expansion coefficients, like glass-filled nylon, reduce warpage by maintaining dimensional stability under temperature fluctuations. Careful selection of resins with appropriate melt flow indices and crystallinity levels helps minimize dimensional deviations, ensuring precision in molded parts.

Design Considerations to Minimize Defects

To minimize shrinkage and warpage defects, designers should optimize material selection by choosing polymers with low shrinkage rates and consistent thermal expansion properties. Incorporating uniform wall thickness and symmetrical part geometry helps ensure even cooling and reduces internal stresses. Implementing strategic gate locations and proper cooling channel designs further controls temperature gradients, thereby minimizing deformation risks during the molding process.

Processing Conditions: Shrinkage vs Warpage

Processing conditions significantly influence shrinkage and warpage in molded parts, with temperature, cooling rate, and mold design playing critical roles. Elevated mold and melt temperatures can reduce shrinkage by ensuring uniform polymer flow and crystallization, whereas uneven cooling rates often contribute to warpage due to differential contraction. Optimizing injection pressure and cooling time minimizes dimensional inconsistencies, as balanced processing conditions control internal stresses that lead to both shrinkage and warpage.

Detection and Measurement Techniques

Shrinkage detection relies heavily on precise dimensional measurement tools such as calipers, micrometers, and coordinate measuring machines (CMM) to identify material loss during cooling. Warpage measurement often utilizes laser scanning, 3D imaging, and strain gauges to capture surface deformation and curvature changes accurately. Your choice of technique depends on the part complexity and required tolerance levels, ensuring reliable quality control throughout the manufacturing process.

Preventive Strategies for Shrinkage

Preventive strategies for shrinkage focus on optimizing material selection, adjusting cooling rates, and maintaining uniform wall thickness to minimize volume reduction during solidification. Proper mold design and controlled processing parameters help ensure consistent product quality by reducing internal stresses and uneven contraction. Your ability to implement these techniques can significantly enhance dimensional stability and reduce defects in molded components.

Solutions to Address Warpage Issues

To address warpage issues in manufacturing, implementing controlled cooling rates and optimizing mold design are essential to minimize uneven shrinkage. Using materials with suitable thermal expansion properties and adjusting processing parameters can significantly reduce deformation during solidification. Your production process benefits from these strategies by ensuring dimensional accuracy and enhancing overall product quality.

Comparing Shrinkage and Warpage: Key Takeaways

Shrinkage refers to the reduction in material volume during cooling, often causing dimensional inaccuracies in molded parts, while warpage is the distortion or bending of a part after solidification, leading to functional and aesthetic defects. Controlling process parameters like temperature, cooling rate, and material composition is crucial to minimizing both shrinkage and warpage in manufacturing. Accurate simulation tools help predict and differentiate between shrinkage-induced size changes and warpage-induced shape deformations, enhancing product quality and reducing defects.

Shrinkage vs Warpage Infographic

libmatt.com

libmatt.com