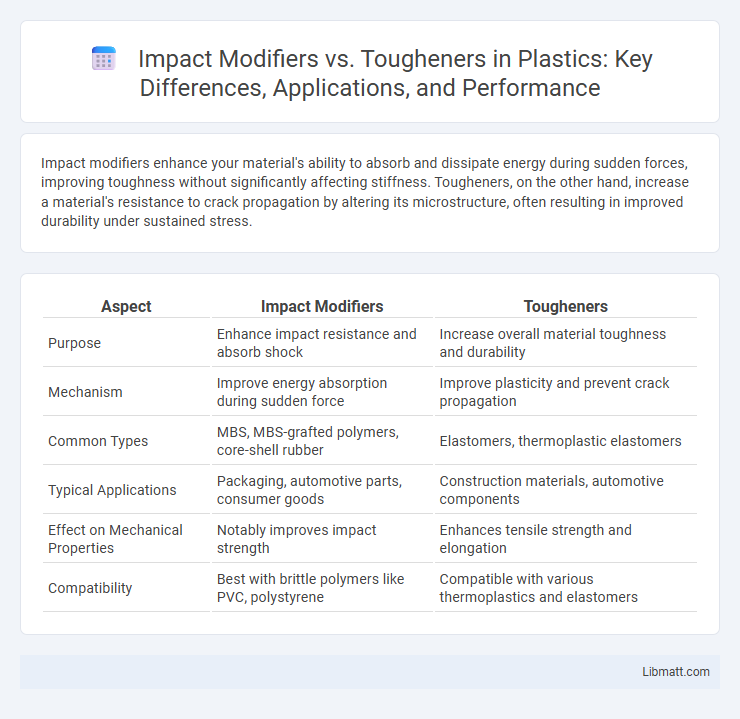

Impact modifiers enhance your material's ability to absorb and dissipate energy during sudden forces, improving toughness without significantly affecting stiffness. Tougheners, on the other hand, increase a material's resistance to crack propagation by altering its microstructure, often resulting in improved durability under sustained stress.

Table of Comparison

| Aspect | Impact Modifiers | Tougheners |

|---|---|---|

| Purpose | Enhance impact resistance and absorb shock | Increase overall material toughness and durability |

| Mechanism | Improve energy absorption during sudden force | Improve plasticity and prevent crack propagation |

| Common Types | MBS, MBS-grafted polymers, core-shell rubber | Elastomers, thermoplastic elastomers |

| Typical Applications | Packaging, automotive parts, consumer goods | Construction materials, automotive components |

| Effect on Mechanical Properties | Notably improves impact strength | Enhances tensile strength and elongation |

| Compatibility | Best with brittle polymers like PVC, polystyrene | Compatible with various thermoplastics and elastomers |

Understanding Impact Modifiers and Tougheners

Impact modifiers are additives designed to enhance a material's resistance to sudden forces and reduce brittleness, often used in plastics and polymers to improve toughness. Tougheners specifically increase the energy absorption capability and ductility of a material, making it less susceptible to cracking under stress. Understanding the differences between impact modifiers and tougheners helps you select the right additive for improving product durability and performance in various industrial applications.

Chemical Composition and Mechanisms

Impact modifiers are typically acrylic or rubber-based polymers designed to absorb and dissipate energy through localized deformation, improving toughness without significantly altering the rigidity of the base material. Tougheners often consist of elastomeric or thermoplastic phases that enhance fracture resistance by promoting mechanisms such as crazing, shear yielding, or plastic deformation within the polymer matrix. The chemical composition of impact modifiers usually favors compatibility with the host polymer for energy absorption, whereas tougheners possess a more diverse chemical structure aimed at modifying the matrix morphology to arrest crack propagation.

Key Differences Between Impact Modifiers and Tougheners

Impact modifiers enhance polymer toughness by improving resistance to sudden forces and impacts without compromising stiffness, often used in flexible applications like packaging. Tougheners increase material toughness primarily by enhancing crack resistance and elongation at break, making them ideal for structural components requiring durability under prolonged stress. Your choice depends on whether the primary need is to absorb rapid impacts or improve long-term fracture resistance in engineered plastics.

Applications in Polymer Engineering

Impact modifiers enhance the toughness and resistance of polymers to sudden shocks in applications like automotive bumpers, packaging films, and electrical housings. Tougheners improve polymer flexibility and durability under stress, commonly used in aerospace components, construction materials, and sports equipment. Your choice between impact modifiers and tougheners depends on the required balance of impact resistance and material flexibility for specific polymer engineering applications.

Performance Metrics: Toughness, Flexibility, and Durability

Impact modifiers enhance toughness by absorbing energy during sudden impacts, improving your material's resistance to cracking. Tougheners increase flexibility by altering the polymer matrix, allowing for greater elongation before failure. Both contribute to durability, but impact modifiers are specialized for shock resistance, while tougheners provide sustained mechanical performance under stress.

Processing Methods and Compatibility

Impact modifiers enhance polymer toughness by improving energy absorption during processing methods like extrusion and injection molding, where melt viscosity and dispersion are critical for uniform distribution. Tougheners typically require specific compatibilizers to ensure good interfacial adhesion between polymer phases, thus maintaining mechanical integrity in blends or composites. Your choice depends on the polymer matrix and processing conditions to optimize compatibility and achieve desired impact resistance.

Industry-Specific Use Cases

Impact modifiers are widely used in the automotive and packaging industries to enhance the toughness and resistance of polymers against sudden impacts, ensuring durability and safety in vehicle parts and product containers. Tougheners, on the other hand, are primarily utilized in electronics and construction materials to improve crack resistance and long-term structural integrity under stress. Your selection between impact modifiers and tougheners should align with the specific mechanical and environmental requirements of your industry's applications.

Environmental Impact and Sustainability

Impact modifiers enhance polymer flexibility and toughness but often rely on petrochemical-based materials with limited biodegradability, raising concerns about long-term environmental impact. Tougheners, designed to improve fracture resistance, increasingly incorporate bio-based or recycled components, promoting better sustainability profiles by reducing carbon footprint and landfill waste. Selecting environmentally friendly tougheners over traditional impact modifiers supports circular economy goals through improved material lifecycle and lower ecological toxicity.

Cost Considerations and Market Trends

Impact modifiers generally offer a cost-effective solution for enhancing the toughness of polymers, making them popular in large-scale manufacturing with budget constraints. Tougheners, often more specialized and with higher performance capabilities, come at a premium price but are favored in markets demanding superior durability and resistance. Understanding Your specific application needs and budget will guide the optimal balance between cost and performance amid evolving market trends favoring sustainable and high-performance materials.

Choosing the Right Additive for Your Application

Impact modifiers enhance polymer flexibility and crack resistance by improving energy absorption during stress, making them ideal for applications requiring durability under dynamic loads. Tougheners increase the overall toughness and fracture resistance, often by blending with the base resin to improve impact strength without compromising rigidity. Choosing the right additive depends on your specific application requirements, such as the type of stress, environmental conditions, and desired mechanical properties.

Impact Modifiers vs Tougheners Infographic

libmatt.com

libmatt.com