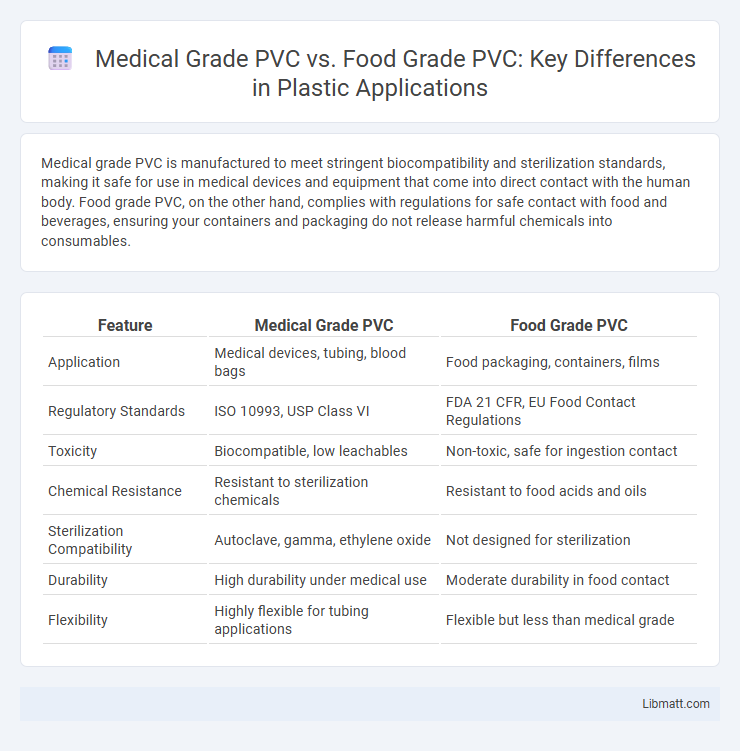

Medical grade PVC is manufactured to meet stringent biocompatibility and sterilization standards, making it safe for use in medical devices and equipment that come into direct contact with the human body. Food grade PVC, on the other hand, complies with regulations for safe contact with food and beverages, ensuring your containers and packaging do not release harmful chemicals into consumables.

Table of Comparison

| Feature | Medical Grade PVC | Food Grade PVC |

|---|---|---|

| Application | Medical devices, tubing, blood bags | Food packaging, containers, films |

| Regulatory Standards | ISO 10993, USP Class VI | FDA 21 CFR, EU Food Contact Regulations |

| Toxicity | Biocompatible, low leachables | Non-toxic, safe for ingestion contact |

| Chemical Resistance | Resistant to sterilization chemicals | Resistant to food acids and oils |

| Sterilization Compatibility | Autoclave, gamma, ethylene oxide | Not designed for sterilization |

| Durability | High durability under medical use | Moderate durability in food contact |

| Flexibility | Highly flexible for tubing applications | Flexible but less than medical grade |

Introduction to PVC and Its Applications

PVC, or polyvinyl chloride, is a versatile synthetic polymer widely used in medical and food industries due to its durability and chemical resistance. Medical grade PVC is specifically formulated to meet stringent biocompatibility, sterilization, and safety standards required for devices such as IV bags, tubing, and catheters. Food grade PVC complies with FDA and EU regulations to ensure non-toxicity and contamination prevention, commonly used in food packaging, storage containers, and processing equipment.

What is Medical Grade PVC?

Medical grade PVC is a high-purity polyvinyl chloride specifically manufactured to meet stringent biocompatibility and safety standards for medical applications. It exhibits exceptional flexibility, chemical resistance, and sterilization tolerance, making it ideal for devices like blood bags, tubing, and catheters. This type of PVC undergoes rigorous testing to ensure minimal leachable substances and contaminants, ensuring patient safety and compliance with FDA and ISO regulations.

What is Food Grade PVC?

Food Grade PVC is a type of polyvinyl chloride specifically formulated to meet strict safety standards set by regulatory agencies like the FDA, ensuring it does not release harmful chemicals when in contact with food. This material is non-toxic, resistant to contamination, and designed for use in food packaging, processing, and storage applications. You can trust Food Grade PVC to maintain the integrity and safety of consumable products throughout the supply chain.

Key Differences in Composition

Medical grade PVC contains higher purity plasticizers and stabilizers to meet strict biocompatibility and sterilization standards, ensuring safety for direct patient contact. Food grade PVC is formulated to avoid harmful additives, complying with FDA regulations to prevent contamination during food storage or packaging. Your choice between these materials should consider the specific requirements for safety, chemical resistance, and regulatory compliance based on the intended application.

Safety Standards and Regulatory Compliance

Medical Grade PVC adheres to stringent safety standards set by regulatory bodies such as the FDA and ISO, ensuring biocompatibility and non-toxicity for use in medical devices and patient care. Food Grade PVC complies with FDA regulations focused on preventing contamination and chemical leaching, making it safe for contact with consumables. Understanding these regulatory frameworks helps you choose the appropriate PVC type based on required safety and compliance for your specific application.

Common Uses of Medical Grade PVC

Medical Grade PVC is commonly used in the manufacturing of intravenous (IV) bags, blood bags, and tubing for catheters due to its biocompatibility and sterilization capability. It is also found in respiratory masks, wound drainage devices, and other critical medical equipment where patient safety and hypoallergenic properties are paramount. The material's flexibility and resistance to chemicals make it ideal for single-use medical applications requiring high hygiene standards.

Common Uses of Food Grade PVC

Food grade PVC is commonly utilized in packaging materials such as cling films, food containers, and tubing for food processing due to its compliance with FDA regulations ensuring safety and non-toxicity. Its versatility extends to applications in dairy and beverage industries, where it prevents contamination while maintaining product integrity. When choosing materials for food handling or storage, your selection of food grade PVC guarantees adherence to hygiene standards and helps preserve the quality of consumables.

Performance and Durability Comparison

Medical grade PVC offers superior biocompatibility, chemical resistance, and sterilization tolerance compared to food grade PVC, making it ideal for medical devices and healthcare applications. Food grade PVC is designed to meet strict safety standards for food contact but typically has lower resistance to high temperatures and repeated sterilization cycles. Your choice depends on the need for enhanced durability and performance in medical environments versus the safety requirements for food packaging.

Cost Considerations

Medical Grade PVC typically incurs higher costs than Food Grade PVC due to stringent manufacturing standards and certifications required for biocompatibility and safety in medical applications. Food Grade PVC is more cost-effective, designed to meet FDA regulations for contact with consumables but lacks the specialized formulations needed for medical use. Evaluating your project's budget and compliance needs will help determine the appropriate PVC grade while balancing performance and expense.

Choosing the Right PVC for Your Needs

Medical Grade PVC offers superior biocompatibility and chemical resistance, making it ideal for applications requiring strict hygiene and safety standards such as medical tubing and equipment. Food Grade PVC meets regulatory standards for food contact, ensuring no harmful contaminants leach into consumables, which is essential for packaging and food processing. Selecting the right PVC depends on the specific regulatory and safety requirements of the application, prioritizing medical grade for healthcare uses and food grade for consumable-related purposes.

Medical Grade PVC vs Food Grade PVC Infographic

libmatt.com

libmatt.com