Tackifiers improve the stickiness and adhesion of materials by increasing their surface tack, making your products more effective in bonding applications. Compatibilizers, on the other hand, enhance the compatibility and interfacial adhesion between different polymers or materials, promoting better blend uniformity and mechanical properties.

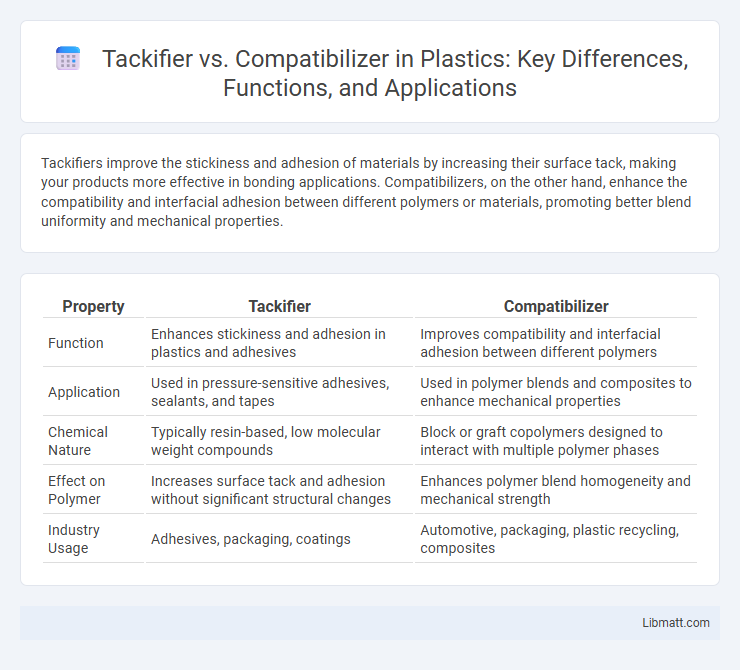

Table of Comparison

| Property | Tackifier | Compatibilizer |

|---|---|---|

| Function | Enhances stickiness and adhesion in plastics and adhesives | Improves compatibility and interfacial adhesion between different polymers |

| Application | Used in pressure-sensitive adhesives, sealants, and tapes | Used in polymer blends and composites to enhance mechanical properties |

| Chemical Nature | Typically resin-based, low molecular weight compounds | Block or graft copolymers designed to interact with multiple polymer phases |

| Effect on Polymer | Increases surface tack and adhesion without significant structural changes | Enhances polymer blend homogeneity and mechanical strength |

| Industry Usage | Adhesives, packaging, coatings | Automotive, packaging, plastic recycling, composites |

Understanding Tackifiers: Definition and Role

Tackifiers are specialized additives used primarily to enhance the stickiness and adhesion properties of adhesives, sealants, and pressure-sensitive tapes. They improve the tack or initial stickiness of polymeric materials without significantly altering their mechanical strength or flexibility. Your formulation's performance can be fine-tuned by selecting the appropriate tackifier, ensuring optimal bonding and application in various industrial processes.

What Are Compatibilizers?

Compatibilizers are specialized additives used in polymer blends to enhance interfacial adhesion between chemically dissimilar materials, improving the overall mechanical properties and stability of the composite. Unlike tackifiers, which increase stickiness and surface tack for adhesives, compatibilizers function at the molecular level to promote compatibility and dispersion of incompatible polymers in your formulation. Their role is critical in applications involving mixed polymers or blends where phase separation negatively affects performance.

Key Chemical Differences Between Tackifiers and Compatibilizers

Tackifiers primarily consist of low molecular weight resins designed to enhance adhesive properties by increasing stickiness and tack strength in polymers. Compatibilizers are typically block or graft copolymers that improve the interfacial adhesion between immiscible polymer blends by promoting molecular compatibility. Your choice between these additives depends on whether you need to increase surface adhesion (tackifiers) or enhance blend homogeneity and mechanical performance (compatibilizers).

Applications of Tackifiers in Industry

Tackifiers enhance adhesion in industries such as pressure-sensitive adhesives, packaging, and automotive sealants by improving the stickiness of polymers without altering their viscosity significantly. Your choice of tackifier can optimize product performance in adhesives for tapes, labels, and protective films, ensuring strong initial tack and long-term durability. These additives are critical in manufacturing processes requiring controlled adhesion and compatibility with various substrates.

Applications of Compatibilizers in Polymer Blends

Compatibilizers enhance the interfacial adhesion and dispersion between immiscible polymer blends, improving mechanical properties and stability in applications such as automotive parts, packaging films, and adhesives. Your polymer blends benefit from improved compatibility, resulting in enhanced durability, impact resistance, and processability. These additives enable the creation of high-performance materials tailored to specific industrial requirements.

Effects on Adhesion: Tackifier vs Compatibilizer

Tackifiers enhance adhesion by increasing the stickiness of polymers, improving initial bond strength in pressure-sensitive adhesives and coatings. Compatibilizers promote interfacial adhesion between dissimilar polymers in blends or composites, enhancing overall mechanical properties and durability. While tackifiers primarily affect surface tack, compatibilizers improve the compatibility and cohesion within multi-phase systems.

Mechanical Properties Comparison

Tackifiers improve adhesion and surface tack without significantly altering the mechanical strength of materials, making them ideal for enhancing bond strength in adhesives and coatings. Compatibilizers enhance the interfacial bonding between dissimilar polymers, leading to improved tensile strength, impact resistance, and elongation, which results in better overall mechanical performance of polymer blends. Your choice depends on whether you need to boost surface adhesion or improve the mechanical integration of incompatible polymer systems.

Selection Criteria: When to Use Tackifiers or Compatibilizers

Tackifiers are selected when enhancing adhesion in pressure-sensitive adhesives, enabling better tack and initial stickiness on diverse surfaces. Compatibilizers are chosen for improving the interfacial compatibility between immiscible polymers in blends or composites, promoting uniform dispersion and mechanical properties. Selection depends on whether the goal is to increase surface adhesion (tackifier) or to improve polymer blend morphology and performance (compatibilizer).

Market Trends and Innovations

The global tackifier market is experiencing significant growth driven by increasing demand in adhesives, particularly in packaging and construction sectors, with innovation focusing on bio-based and eco-friendly formulations to meet sustainable industry standards. Compatibilizer market trends highlight advancements in polymer blends for automotive and electronics applications, aiming to enhance material compatibility and performance while reducing production costs. Recent innovations include novel block copolymers and reactive compatibilizers that improve mechanical properties and recyclability, reflecting a strong focus on circular economy principles within both markets.

Future Perspectives in Polymer Engineering

Tackifiers enhance adhesive properties by promoting surface stickiness, while compatibilizers improve the interfacial adhesion between immiscible polymer blends, crucial for developing advanced composite materials. Future polymer engineering trends emphasize multifunctional additives that combine tackifying and compatibilizing roles to optimize mechanical performance and durability in sustainable polymers. Innovations in bio-based compatibilizers and eco-friendly tackifiers are driving the shift towards greener manufacturing processes and high-performance recyclable materials.

Tackifier vs compatibilizer Infographic

libmatt.com

libmatt.com