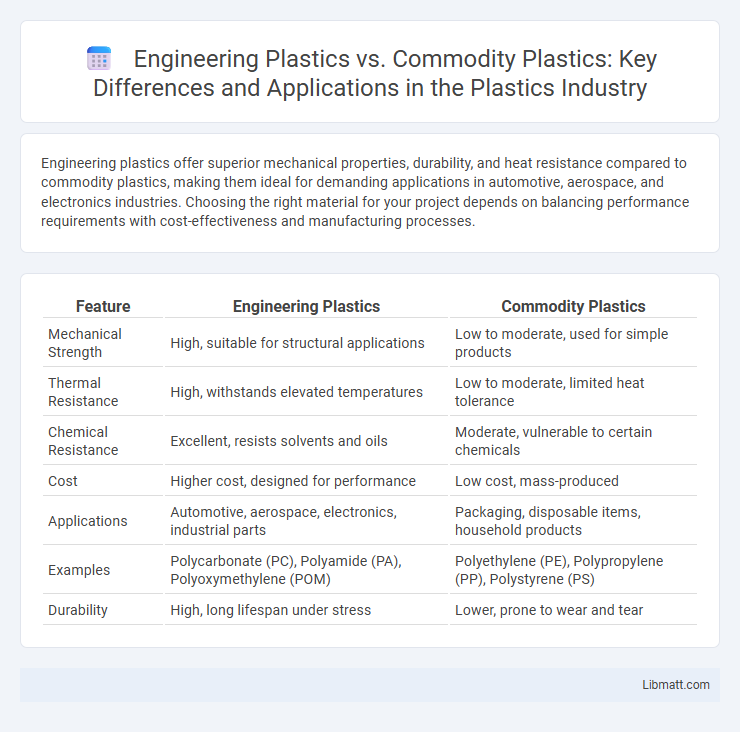

Engineering plastics offer superior mechanical properties, durability, and heat resistance compared to commodity plastics, making them ideal for demanding applications in automotive, aerospace, and electronics industries. Choosing the right material for your project depends on balancing performance requirements with cost-effectiveness and manufacturing processes.

Table of Comparison

| Feature | Engineering Plastics | Commodity Plastics |

|---|---|---|

| Mechanical Strength | High, suitable for structural applications | Low to moderate, used for simple products |

| Thermal Resistance | High, withstands elevated temperatures | Low to moderate, limited heat tolerance |

| Chemical Resistance | Excellent, resists solvents and oils | Moderate, vulnerable to certain chemicals |

| Cost | Higher cost, designed for performance | Low cost, mass-produced |

| Applications | Automotive, aerospace, electronics, industrial parts | Packaging, disposable items, household products |

| Examples | Polycarbonate (PC), Polyamide (PA), Polyoxymethylene (POM) | Polyethylene (PE), Polypropylene (PP), Polystyrene (PS) |

| Durability | High, long lifespan under stress | Lower, prone to wear and tear |

Introduction to Engineering Plastics and Commodity Plastics

Engineering plastics offer superior mechanical properties, thermal resistance, and chemical stability compared to commodity plastics, making them ideal for high-performance applications. Commodity plastics, such as polyethylene and polypropylene, are cost-effective, widely used materials suitable for everyday products with less demanding performance requirements. Understanding the differences between engineering plastics and commodity plastics helps you choose the right material based on strength, durability, and application needs.

Chemical Structure and Composition Differences

Engineering plastics possess intricate chemical structures with high molecular weight polymers and added reinforcing agents, enhancing mechanical strength and thermal resistance. Commodity plastics feature simpler, lower molecular weight polymers that provide cost-effective options for mass production but lack durability and heat tolerance. Understanding these differences in chemical composition enables you to select the right plastic type tailored to specific performance requirements and environmental conditions.

Mechanical and Physical Properties Comparison

Engineering plastics exhibit superior mechanical and physical properties compared to commodity plastics, including higher tensile strength, greater impact resistance, and improved thermal stability. These materials typically offer enhanced wear resistance and dimensional stability, making them suitable for demanding applications in automotive, aerospace, and industrial sectors. In contrast, commodity plastics generally have lower strength and heat resistance, being more cost-effective but limited to less rigorous environments.

Common Types of Engineering Plastics

Common types of engineering plastics include polycarbonate (PC), known for its high impact resistance and optical clarity, acrylonitrile butadiene styrene (ABS), valued for toughness and ease of processing, and polyamide (PA or nylon), which offers excellent mechanical strength and thermal stability. Polyoxymethylene (POM or acetal) is widely used for precision parts requiring low friction and high stiffness, while polyether ether ketone (PEEK) excels in chemical resistance and high-temperature applications. These engineering plastics outperform commodity plastics like polyethylene (PE) and polypropylene (PP) in durability, mechanical properties, and thermal resistance, making them ideal for demanding industrial and automotive uses.

Common Types of Commodity Plastics

Commodity plastics commonly include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polystyrene (PS), each known for their affordability and widespread industrial use. These plastics offer basic mechanical properties suitable for packaging, containers, and household goods but generally lack the higher performance required in engineering applications. Their ease of processing and low cost make commodity plastics ideal for mass-produced products, though they cannot match the durability, heat resistance, or strength of engineering plastics like polycarbonate or nylon.

Applications in Industry and Everyday Life

Engineering plastics like polycarbonate and nylon offer superior mechanical strength and thermal resistance, making them ideal for automotive parts, aerospace components, and high-performance electrical devices. Commodity plastics such as polyethylene and polypropylene are widely used in packaging, household containers, and disposable products due to their cost-effectiveness and ease of processing. The choice between engineering and commodity plastics depends on performance requirements, durability, and application environment in both industrial and everyday contexts.

Performance Under Stress and Temperature

Engineering plastics exhibit superior performance under stress and high temperatures due to their enhanced mechanical properties, including high tensile strength and thermal stability, which allows them to maintain integrity in demanding applications. Commodity plastics, such as polyethylene and polypropylene, tend to have lower temperature resistance and mechanical strength, limiting their use in environments where prolonged exposure to heat or mechanical load is present. The superior thermal resistance of engineering plastics, often exceeding 150degC, ensures reliable performance in automotive, aerospace, and industrial applications, whereas commodity plastics typically perform optimally below 100degC.

Cost and Economic Considerations

Engineering plastics typically have higher initial costs compared to commodity plastics due to superior mechanical properties and better performance in demanding applications. Your choice of materials should balance budget constraints with long-term durability, as engineering plastics often reduce total lifecycle costs by minimizing maintenance and replacement expenses. Commodity plastics offer lower upfront costs, making them suitable for high-volume, low-stress applications where economic efficiency is critical.

Environmental Impact and Recycling Options

Engineering plastics offer superior durability and thermal stability, which often results in longer product lifespans and reduced material waste compared to commodity plastics such as polyethylene or polypropylene. However, engineering plastics like polycarbonate and ABS generally present more complex recycling challenges due to their chemical composition and mixed material use, limiting recycling efficiency and increasing environmental impact. Commodity plastics are more widely accepted in recycling programs, facilitating easier reuse and contributing to lower environmental footprints when properly managed.

Selecting the Right Plastic for Your Application

Selecting the right plastic for your application depends on understanding the specific performance requirements such as strength, heat resistance, and chemical stability. Engineering plastics like polycarbonate, ABS, and nylon offer superior mechanical properties and durability for demanding environments, whereas commodity plastics such as polyethylene and polypropylene are cost-effective for less critical uses. Evaluating factors like load-bearing capacity, operating temperature, and environmental exposure ensures optimal material selection for both functionality and budget.

Engineering Plastics vs Commodity Plastics Infographic

libmatt.com

libmatt.com