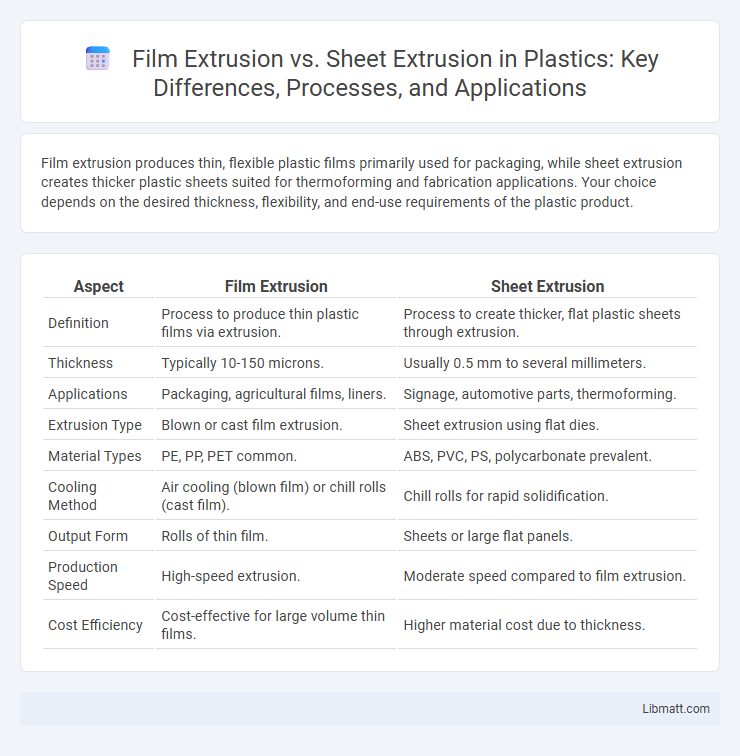

Film extrusion produces thin, flexible plastic films primarily used for packaging, while sheet extrusion creates thicker plastic sheets suited for thermoforming and fabrication applications. Your choice depends on the desired thickness, flexibility, and end-use requirements of the plastic product.

Table of Comparison

| Aspect | Film Extrusion | Sheet Extrusion |

|---|---|---|

| Definition | Process to produce thin plastic films via extrusion. | Process to create thicker, flat plastic sheets through extrusion. |

| Thickness | Typically 10-150 microns. | Usually 0.5 mm to several millimeters. |

| Applications | Packaging, agricultural films, liners. | Signage, automotive parts, thermoforming. |

| Extrusion Type | Blown or cast film extrusion. | Sheet extrusion using flat dies. |

| Material Types | PE, PP, PET common. | ABS, PVC, PS, polycarbonate prevalent. |

| Cooling Method | Air cooling (blown film) or chill rolls (cast film). | Chill rolls for rapid solidification. |

| Output Form | Rolls of thin film. | Sheets or large flat panels. |

| Production Speed | High-speed extrusion. | Moderate speed compared to film extrusion. |

| Cost Efficiency | Cost-effective for large volume thin films. | Higher material cost due to thickness. |

Introduction to Film and Sheet Extrusion

Film extrusion produces thin, flexible plastic films commonly used for packaging, labels, and laminates, utilizing techniques like blown or cast film processes that ensure uniform thickness and clarity. Sheet extrusion creates thicker, rigid plastic sheets suitable for applications such as signage, automotive components, and thermoforming, achieved through a flat die and careful cooling to maintain flatness and surface quality. Both methods rely on the extrusion of molten polymers but differ in die design, cooling methods, and output form to meet distinct industry needs.

Key Principles of Film Extrusion

Film extrusion involves melting plastic resin and forcing it through a flat or tubular die to create thin, flexible sheets or films with controlled thickness and width. This process emphasizes precise temperature control, cooling rate, and stretching to achieve desired mechanical properties and clarity. Understanding these key principles helps optimize your production efficiency and film quality compared to sheet extrusion.

Core Process of Sheet Extrusion

Sheet extrusion involves melting plastic resin and forcing it through a flat die to produce continuous plastic sheets with uniform thickness and smooth surfaces. The process relies on precise temperature control and die gap adjustments to ensure dimensional accuracy and consistency. Unlike film extrusion, sheet extrusion typically uses higher resin melt viscosity to achieve rigidity and structural integrity for applications such as thermoforming and signage.

Comparison of Equipment Used

Film extrusion equipment typically includes blown film extruders or cast film lines designed for producing thin, flexible plastic sheets with high clarity and uniform thickness. Sheet extrusion machines use single or twin-screw extruders combined with a sheet die and calendaring or cooling rollers to create thicker, rigid sheets suited for applications like thermoforming and signage. The key equipment differences lie in die design and downstream processing, with film extrusion emphasizing rapid cooling and film winding systems, while sheet extrusion prioritizes flatness control and dimensional stability.

Material Compatibility Differences

Film extrusion primarily uses low-density and linear low-density polyethylene (LDPE and LLDPE) due to their flexibility and clarity, while sheet extrusion favors high-density polyethylene (HDPE), polypropylene (PP), and polystyrene (PS) for rigidity and strength. Material compatibility in film extrusion is crucial for producing thin, uniform films with excellent sealability, whereas sheet extrusion demands materials with high stiffness and impact resistance for applications like packaging and thermoforming. Your choice between film and sheet extrusion depends on the desired material properties and end-use requirements, influencing the selection of polymers based on their thermal and mechanical characteristics.

Thickness and Dimensional Properties

Film extrusion produces thin, flexible layers typically ranging from 0.5 to 100 microns, offering precise control over uniform thickness and consistent dimensional properties critical for packaging applications. In contrast, sheet extrusion creates thicker, rigid products measuring from 0.5 mm to several millimeters, with dimensional properties emphasizing flatness, stiffness, and structural integrity for thermoforming and fabrication uses. The thickness stability in film extrusion is crucial for barrier performance, while sheet extrusion prioritizes uniform thickness distribution to maintain mechanical strength.

Applications in Industry

Film extrusion is primarily used for producing thin plastic films for packaging, agricultural covers, and protective wraps, offering flexibility and lightweight properties essential in food and consumer goods industries. Sheet extrusion produces thicker plastic sheets ideal for automotive parts, signage, and construction materials, providing rigidity and durability for structural applications. Your choice between these methods depends on whether you require film's adaptability or sheet's strength for your industrial needs.

Advantages of Film Extrusion

Film extrusion offers superior flexibility in producing ultra-thin, uniform plastic films with high tensile strength, making it ideal for packaging applications requiring durability and transparency. The process enables faster production speeds and material savings due to precise control over film thickness and width. You benefit from enhanced barrier properties and improved surface quality compared to sheet extrusion, optimizing your product's performance and cost-efficiency.

Benefits of Sheet Extrusion

Sheet extrusion provides superior uniform thickness and surface finish, making it ideal for applications requiring precise dimensions and high-quality aesthetics. This process enhances mechanical properties and strength, offering better rigidity compared to film extrusion. Your manufacturing efficiency improves with consistent sheet output, reducing material waste and post-processing requirements.

Choosing the Right Extrusion Method

Choosing the right extrusion method depends on the desired product characteristics and application requirements, with film extrusion suitable for producing thin, flexible plastic films used in packaging and sheet extrusion ideal for creating thicker, rigid plastic sheets used in thermoforming and industrial applications. Film extrusion employs a blown or cast process to achieve uniform thickness and clarity, while sheet extrusion uses a flat die to produce consistent thickness and dimensional stability. Understanding these differences ensures optimal material performance, cost-efficiency, and manufacturing speed for specific end-use products.

Film Extrusion vs Sheet Extrusion Infographic

libmatt.com

libmatt.com