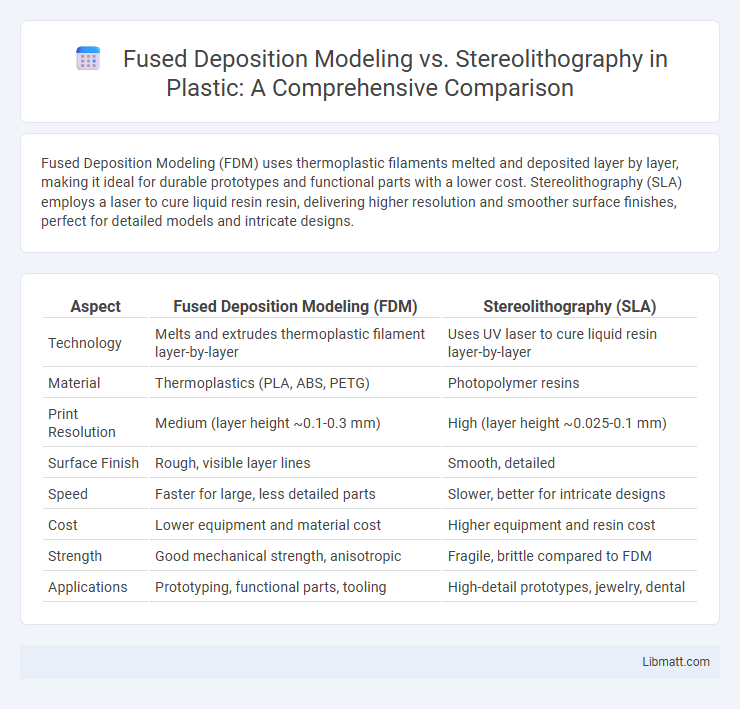

Fused Deposition Modeling (FDM) uses thermoplastic filaments melted and deposited layer by layer, making it ideal for durable prototypes and functional parts with a lower cost. Stereolithography (SLA) employs a laser to cure liquid resin resin, delivering higher resolution and smoother surface finishes, perfect for detailed models and intricate designs.

Table of Comparison

| Aspect | Fused Deposition Modeling (FDM) | Stereolithography (SLA) |

|---|---|---|

| Technology | Melts and extrudes thermoplastic filament layer-by-layer | Uses UV laser to cure liquid resin layer-by-layer |

| Material | Thermoplastics (PLA, ABS, PETG) | Photopolymer resins |

| Print Resolution | Medium (layer height ~0.1-0.3 mm) | High (layer height ~0.025-0.1 mm) |

| Surface Finish | Rough, visible layer lines | Smooth, detailed |

| Speed | Faster for large, less detailed parts | Slower, better for intricate designs |

| Cost | Lower equipment and material cost | Higher equipment and resin cost |

| Strength | Good mechanical strength, anisotropic | Fragile, brittle compared to FDM |

| Applications | Prototyping, functional parts, tooling | High-detail prototypes, jewelry, dental |

Introduction to Fused Deposition Modeling and Stereolithography

Fused Deposition Modeling (FDM) builds objects by extruding thermoplastic filaments layer by layer, ideal for prototyping and functional parts due to its material versatility and cost-effectiveness. Stereolithography (SLA) uses a UV laser to cure liquid resin into hardened plastic in precise, smooth layers, delivering high-resolution and detailed prints suitable for intricate designs or detailed prototypes. Understanding your project's requirements helps determine whether the robust, accessible FDM or the high-detail, surface-finish-focused SLA process best fits your manufacturing goals.

How Fused Deposition Modeling Works

Fused Deposition Modeling (FDM) works by extruding thermoplastic filament through a heated nozzle that melts the material and deposits it layer by layer to create solid objects. The print head moves in precise X, Y, and Z axes, building each layer according to digital 3D model instructions. Your choice of filament materials, such as PLA or ABS, directly impacts the strength and finish of FDM-printed parts compared to the resin-based process in Stereolithography (SLA).

How Stereolithography Works

Stereolithography operates by using a UV laser to selectively cure liquid photopolymer resin layer by layer, creating precise and highly detailed 3D objects. The laser traces the cross-section of the design on the resin surface, solidifying it before the build platform moves downward for the next layer. This technique offers superior surface finish and fine resolution compared to Fused Deposition Modeling, which extrudes thermoplastic filaments through a heated nozzle.

Material Compatibility and Options

Fused Deposition Modeling (FDM) excels in material compatibility with thermoplastics such as PLA, ABS, PETG, and TPU, offering affordable and widely available filament options. Stereolithography (SLA) primarily uses photopolymer resins, providing superior surface finish and detail but with more limited material properties compared to FDM's diverse thermoplastics. SLA resins include standard, flexible, castable, and high-temperature variants, catering to applications requiring fine resolution and specialized mechanical characteristics.

Print Resolution and Surface Finish Comparison

Fused Deposition Modeling (FDM) typically offers print resolutions around 100-300 microns, producing layer lines that are more visible and result in a rougher surface finish compared to Stereolithography (SLA). SLA achieves superior print resolution as fine as 25-100 microns, enabling highly detailed features with smooth, glass-like surfaces due to its laser-based photopolymerization process. The difference in surface finish and resolution makes SLA ideal for applications requiring intricate detail and aesthetic quality, while FDM suits prototyping where strength and cost efficiency are prioritized.

Speed and Efficiency of Both Technologies

Fused Deposition Modeling (FDM) generally offers faster production speeds due to its straightforward layer-by-layer extrusion of thermoplastic materials, making it suitable for rapid prototyping and larger parts. Stereolithography (SLA) requires longer curing times as it uses photopolymer resin solidified by a UV laser, resulting in slower build speeds but higher precision and surface quality. Efficiency in FDM is enhanced by lower material costs and minimal post-processing, whereas SLA demands more intricate post-curing steps, impacting overall print turnaround time.

Cost Analysis: Equipment and Operating Expenses

Fused Deposition Modeling (FDM) typically features lower equipment costs, with desktop printers available under $1,000, making it accessible for hobbyists and small businesses. Stereolithography (SLA) machines generally demand higher initial investments, often ranging from $3,000 to $10,000, due to their advanced laser and resin curing technology. Operating expenses for FDM remain cost-effective, relying on affordable thermoplastic filaments, whereas SLA involves higher costs related to specialized resins and meticulous post-processing requirements.

Strengths and Limitations of FDM vs SLA

Fused Deposition Modeling (FDM) offers advantages in affordability, material variety, and ease of use, making it ideal for rapid prototyping and functional parts with moderate detail; however, it typically provides lower resolution and surface finish compared to Stereolithography (SLA). SLA excels in producing highly detailed, smooth, and precise models using photopolymer resins, which enhances applications requiring intricate geometry and fine features, though it often involves higher costs and more complex post-processing. Both technologies present trade-offs between mechanical strength, accuracy, speed, and material properties, influencing their suitability based on specific project requirements.

Common Applications in Industry

Fused Deposition Modeling (FDM) is widely used in prototyping, automotive parts, and consumer goods due to its cost-effectiveness and material versatility, utilizing thermoplastic filaments like ABS and PLA. Stereolithography (SLA) excels in producing high-precision, smooth-surfaced components for dentistry, jewelry, and medical models, leveraging photopolymer resins cured by UV lasers. Both technologies serve critical roles in rapid prototyping and low-volume manufacturing, with FDM favored for functional parts and SLA preferred for detailed, intricate designs.

Choosing the Right 3D Printing Method

Fused Deposition Modeling (FDM) excels in producing durable prototypes with thermoplastic materials, making it ideal for functional parts and larger models requiring strength. Stereolithography (SLA) offers superior surface finish and intricate detail resolution by using photopolymer resins, perfect for highly detailed prototypes or jewelry designs. Your choice depends on balancing factors such as material properties, print precision, production speed, and budget constraints to achieve optimal results.

Fused Deposition Modeling vs Stereolithography Infographic

libmatt.com

libmatt.com