Polyvinyl acetate (PVA) is a synthetic polymer commonly used as an adhesive and in paints due to its strong bonding properties and flexibility, while polyvinyl alcohol (PVOH) is a water-soluble synthetic polymer valued for its film-forming ability and biodegradability in applications like packaging and textiles. Your choice between the two depends on whether you need water resistance and adhesion (polyvinyl acetate) or water solubility and environmental friendliness (polyvinyl alcohol).

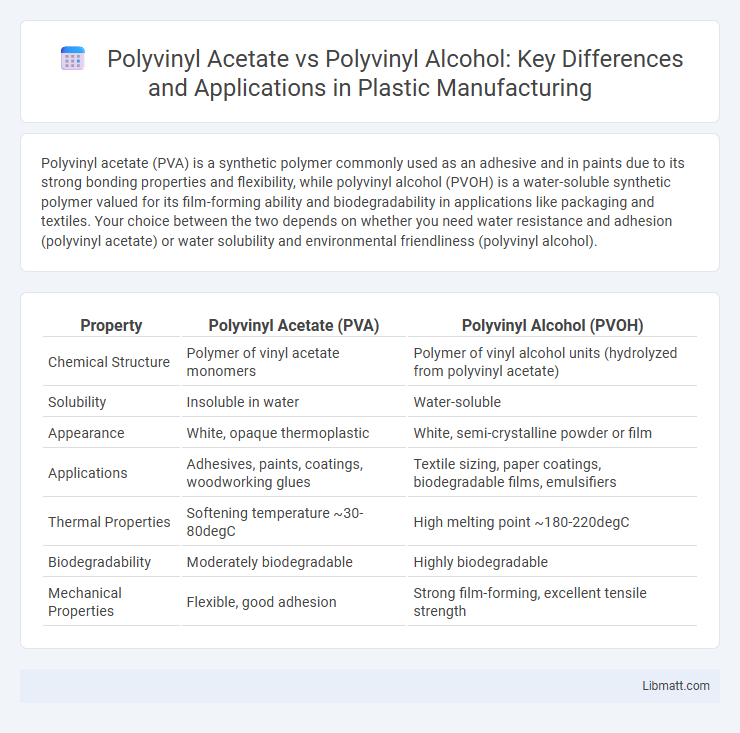

Table of Comparison

| Property | Polyvinyl Acetate (PVA) | Polyvinyl Alcohol (PVOH) |

|---|---|---|

| Chemical Structure | Polymer of vinyl acetate monomers | Polymer of vinyl alcohol units (hydrolyzed from polyvinyl acetate) |

| Solubility | Insoluble in water | Water-soluble |

| Appearance | White, opaque thermoplastic | White, semi-crystalline powder or film |

| Applications | Adhesives, paints, coatings, woodworking glues | Textile sizing, paper coatings, biodegradable films, emulsifiers |

| Thermal Properties | Softening temperature ~30-80degC | High melting point ~180-220degC |

| Biodegradability | Moderately biodegradable | Highly biodegradable |

| Mechanical Properties | Flexible, good adhesion | Strong film-forming, excellent tensile strength |

Introduction to Polyvinyl Acetate and Polyvinyl Alcohol

Polyvinyl acetate (PVA) is a synthetic polymer primarily used as an adhesive, paint binder, and in woodworking, known for its strong bonding properties and flexibility. Polyvinyl alcohol, despite the similar abbreviation (also PVA), is a water-soluble polymer used in textile sizing, films, and medical applications, offering excellent film-forming and emulsifying properties. Understanding the distinct chemical structures and applications of polyvinyl acetate and polyvinyl alcohol helps you select the right polymer for your specific industrial or commercial needs.

Chemical Structure Comparison

Polyvinyl acetate (PVA) consists of repeating vinyl acetate units with ester functional groups, giving it a relatively non-polar and hydrophobic character, while polyvinyl alcohol (also abbreviated PVA) is synthesized through the hydrolysis of polyvinyl acetate, replacing ester groups with hydroxyl groups, which makes it more hydrophilic and polar. This difference in chemical structure influences their solubility, adhesion properties, and applications; polyvinyl acetate is commonly used in adhesives and paints, whereas polyvinyl alcohol is utilized in films, coatings, and as a water-soluble polymer. Understanding the distinct molecular composition of these polymers allows you to select the appropriate material for targeted industrial or commercial uses.

Synthesis and Manufacturing Processes

Polyvinyl acetate (PVAc) is synthesized through the free radical polymerization of vinyl acetate monomers, utilizing initiators such as benzoyl peroxide or AIBN in emulsion or solution polymerization processes. Polyvinyl alcohol (PVA) is produced by the hydrolysis of polyvinyl acetate, where the acetate groups are chemically converted into hydroxyl groups through a controlled alkaline or acidic hydrolysis reaction. The degree of hydrolysis and polymerization significantly impacts the physical properties and applications of PVA, distinguishing it from its precursor PVAc in terms of solubility and film-forming capabilities.

Physical and Mechanical Properties

Polyvinyl acetate (PVA) is a flexible, adhesive polymer with moderate tensile strength and excellent elasticity, commonly used in woodworking and paper coatings due to its strong adhesion and water resistance. Polyvinyl alcohol (PVOH) exhibits higher tensile strength, better chemical resistance, and superior film-forming properties, often utilized in textile sizing and packaging films. While both polymers are water-soluble, polyvinyl alcohol's improved mechanical stability and thermal resistance make it more suitable for applications demanding durability and flexibility under stress.

Water Solubility Differences

Polyvinyl acetate (PVAc) is insoluble in water due to its ester functional groups, which prevent effective hydrogen bonding with water molecules. In contrast, polyvinyl alcohol (PVA) exhibits high water solubility attributed to its hydroxyl groups that enable strong hydrogen bonding. These solubility differences significantly impact their applications in adhesives, coatings, and films.

Adhesive and Film-Forming Capabilities

Polyvinyl acetate (PVA) exhibits superior adhesive properties due to its excellent bonding strength and flexibility, making it ideal for woodworking and paper products, while polyvinyl alcohol (PVOH) forms stronger, more water-resistant films with enhanced tensile strength and barrier qualities. Your choice depends on whether you prioritize adhesive performance or durable, clear film formation, with polyvinyl acetate excelling in glue applications and polyvinyl alcohol preferred for coatings and packaging. Both polymers offer unique film-forming capabilities that cater to specific industrial and commercial needs.

Common Industrial and Commercial Applications

Polyvinyl acetate (PVA) is widely used in adhesives, particularly white glues for woodworking, paper bonding, and packaging. Polyvinyl alcohol (PVOH), on the other hand, is favored in applications requiring water solubility and film-forming properties, such as textile sizing, paper coating, and biodegradable packaging. Your choice between these polymers depends on the specific industrial requirements for adhesion strength or solubility.

Environmental Impact and Biodegradability

Polyvinyl acetate (PVA) exhibits limited biodegradability, often persisting in the environment due to its synthetic polymer structure, which complicates its breakdown by microorganisms. Polyvinyl alcohol (PVOH), on the other hand, is water-soluble and more readily biodegradable, especially under aerobic conditions, making it a favored choice in eco-friendly applications. The environmental impact of PVOH is generally lower, as it decomposes into non-toxic byproducts, whereas PVA's resistance to degradation can contribute to microplastic pollution.

Safety and Handling Considerations

Polyvinyl acetate (PVA) is generally considered safe for handling with minimal toxicity but should be kept away from open flames due to its flammability. Polyvinyl alcohol, while also low in toxicity, requires careful handling to avoid inhalation of dust, which can cause respiratory irritation. Your safety protocols should include proper ventilation and personal protective equipment when working with either polymer to minimize risks.

Choosing the Right Polymer for Your Needs

Polyvinyl acetate (PVA) excels in adhesive applications due to its strong bonding properties and quick drying time, making it ideal for woodworking and paper products. Polyvinyl alcohol (PVOH) offers exceptional water solubility and film-forming capabilities, suited for packaging and textile sizing where flexibility and water resistance are priorities. Selecting between these polymers depends on specific requirements such as adhesion strength, solubility, and environmental exposure to optimize performance.

Polyvinyl acetate vs polyvinyl alcohol Infographic

libmatt.com

libmatt.com