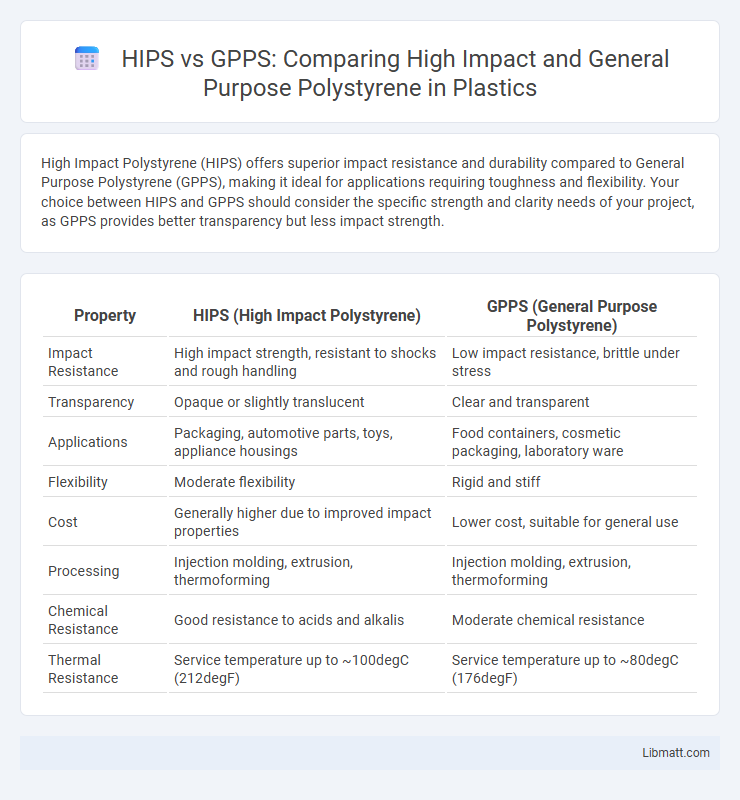

High Impact Polystyrene (HIPS) offers superior impact resistance and durability compared to General Purpose Polystyrene (GPPS), making it ideal for applications requiring toughness and flexibility. Your choice between HIPS and GPPS should consider the specific strength and clarity needs of your project, as GPPS provides better transparency but less impact strength.

Table of Comparison

| Property | HIPS (High Impact Polystyrene) | GPPS (General Purpose Polystyrene) |

|---|---|---|

| Impact Resistance | High impact strength, resistant to shocks and rough handling | Low impact resistance, brittle under stress |

| Transparency | Opaque or slightly translucent | Clear and transparent |

| Applications | Packaging, automotive parts, toys, appliance housings | Food containers, cosmetic packaging, laboratory ware |

| Flexibility | Moderate flexibility | Rigid and stiff |

| Cost | Generally higher due to improved impact properties | Lower cost, suitable for general use |

| Processing | Injection molding, extrusion, thermoforming | Injection molding, extrusion, thermoforming |

| Chemical Resistance | Good resistance to acids and alkalis | Moderate chemical resistance |

| Thermal Resistance | Service temperature up to ~100degC (212degF) | Service temperature up to ~80degC (176degF) |

Introduction to Polystyrene: HIPS vs GPPS

High Impact Polystyrene (HIPS) and General Purpose Polystyrene (GPPS) are two common types of polystyrene distinguished by their mechanical properties and applications. HIPS contains rubber additives, providing enhanced toughness and impact resistance, making it suitable for consumer products requiring durability. GPPS offers clarity and rigidity but is more brittle, often used in applications where transparency and aesthetic appearance are prioritized over strength.

Chemical Structure and Composition Differences

HIPS (High Impact Polystyrene) contains a rubbery polybutadiene phase dispersed within the polystyrene matrix, enhancing its toughness and impact resistance, whereas GPPS (General Purpose Polystyrene) consists of a pure polystyrene homopolymer with a rigid, brittle structure. The chemical structure of HIPS is a two-phase system combining amorphous polystyrene and elastomeric components, while GPPS is a single-phase aromatic polymer formed from styrene monomers. Understanding these compositional differences is essential for selecting the right material based on your application's mechanical performance requirements.

Mechanical Properties Comparison

High Impact Polystyrene (HIPS) exhibits superior impact resistance and toughness compared to General Purpose Polystyrene (GPPS), making it more suitable for applications requiring durability and shock absorption. GPPS offers higher rigidity and better gloss but is more brittle, with lower tensile strength and elongation at break relative to HIPS. The enhanced mechanical properties of HIPS arise from its rubber-modified polymer matrix, which significantly improves impact strength while maintaining adequate stiffness.

Impact Resistance: HIPS vs GPPS

High Impact Polystyrene (HIPS) offers superior impact resistance compared to General Purpose Polystyrene (GPPS), making it ideal for applications requiring durability and toughness. GPPS, being more brittle, tends to crack or shatter under stress, whereas HIPS incorporates rubber modifiers that enhance its ability to absorb shocks and resist breakage. Choosing HIPS over GPPS ensures your products withstand higher mechanical stresses without compromising structural integrity.

Applications and Industry Uses

HIPS (High Impact Polystyrene) offers enhanced impact resistance, making it ideal for applications such as appliance housings, food packaging, and automotive parts that require durability and toughness. GPPS (General Purpose Polystyrene) is preferred for clear, rigid items like disposable cutlery, CD cases, and laboratory ware where clarity and rigidity are critical. Your choice between HIPS and GPPS will depend on the need for impact strength versus optical clarity in industries like packaging, consumer goods, and electronics.

Processing and Molding Techniques

HIPS (High Impact Polystyrene) offers enhanced toughness and impact resistance, making it suitable for injection molding and thermoforming processes requiring durability. GPPS (General Purpose Polystyrene) provides excellent clarity and rigidity, preferred in applications where precise detail and surface finish are critical, typically processed via injection molding and extrusion. Both materials require optimized temperature control during molding, with HIPS tolerating higher shear forces and GPPS demanding careful cooling to prevent warping.

Cost Considerations: HIPS vs GPPS

High Impact Polystyrene (HIPS) generally costs more than General Purpose Polystyrene (GPPS) due to its enhanced impact resistance and added rubber content that improve durability. GPPS is favored for applications prioritizing cost-efficiency and optical clarity, making it a budget-friendly choice for products with low mechanical stress. You should evaluate your project's requirements carefully, as HIPS offers better performance under strain but may increase overall production expenses compared to GPPS.

Environmental Impact and Recycling

HIPS (High Impact Polystyrene) and GPPS (General Purpose Polystyrene) differ significantly in environmental impact and recycling processes. HIPS contains rubber additives that enhance durability but complicate recycling, often requiring specialized facilities, whereas GPPS is more straightforward to recycle due to its pure polystyrene composition. Choosing GPPS can reduce your environmental footprint through easier recycling and lower contamination risks in waste streams.

Key Advantages and Limitations

HIPS (High Impact Polystyrene) offers superior impact resistance and toughness compared to GPPS (General Purpose Polystyrene), making it ideal for applications requiring durability, such as appliance housings and packaging. GPPS provides excellent clarity and rigidity, which suits products needing transparency and dimensional stability but is more brittle and less resistant to impact. The main limitation of HIPS is reduced optical clarity, while GPPS's brittleness limits its use in impact-prone environments.

Choosing Between HIPS and GPPS: Decision Factors

Choosing between HIPS and GPPS involves evaluating impact resistance, clarity, and application requirements; HIPS offers superior toughness and is ideal for durable products, while GPPS provides higher gloss and transparency suited for aesthetic applications. Cost considerations also play a role, with GPPS generally being less expensive but more brittle compared to the more expensive, impact-resistant HIPS. Manufacturing processes such as thermoforming or injection molding further influence the selection based on material flow and finish quality.

HIPS vs GPPS (High Impact vs General Purpose Polystyrene) Infographic

libmatt.com

libmatt.com