Permeability in plastics refers to the ability of a substance, such as a gas or liquid, to pass through a polymer material, combining both the diffusivity and the solubility of the penetrant in the polymer. Diffusivity specifically measures the rate at which molecules move through the polymer matrix, influencing how quickly your material will allow substances to spread internally.

Table of Comparison

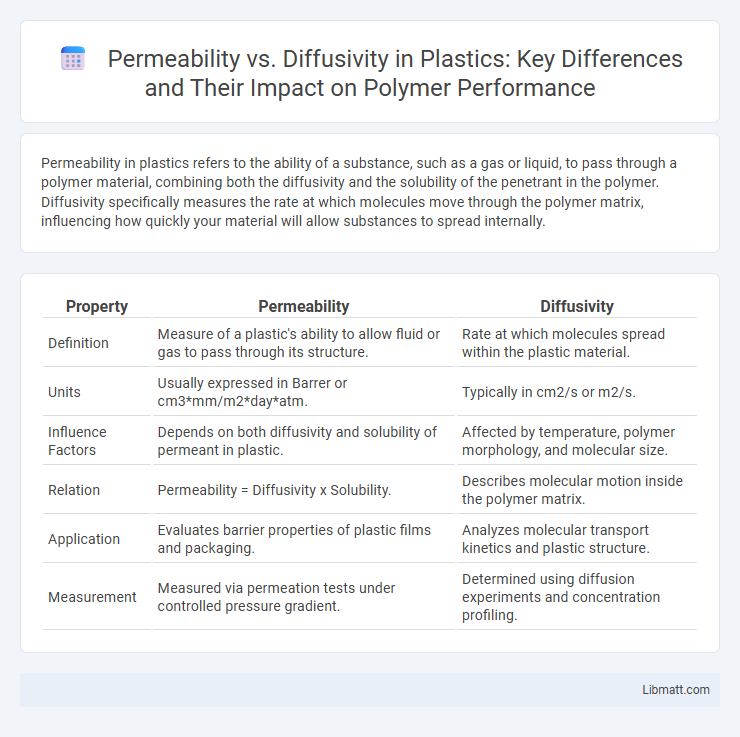

| Property | Permeability | Diffusivity |

|---|---|---|

| Definition | Measure of a plastic's ability to allow fluid or gas to pass through its structure. | Rate at which molecules spread within the plastic material. |

| Units | Usually expressed in Barrer or cm3*mm/m2*day*atm. | Typically in cm2/s or m2/s. |

| Influence Factors | Depends on both diffusivity and solubility of permeant in plastic. | Affected by temperature, polymer morphology, and molecular size. |

| Relation | Permeability = Diffusivity x Solubility. | Describes molecular motion inside the polymer matrix. |

| Application | Evaluates barrier properties of plastic films and packaging. | Analyzes molecular transport kinetics and plastic structure. |

| Measurement | Measured via permeation tests under controlled pressure gradient. | Determined using diffusion experiments and concentration profiling. |

Introduction to Permeability and Diffusivity in Plastics

Permeability in plastics quantifies the rate at which gases or liquids pass through a polymer matrix, influenced by both the material's structure and the penetrant's properties. Diffusivity measures the speed at which molecules move within the plastic, reflecting the ease of molecular transport through free volume or microvoids. Understanding permeability and diffusivity is essential for designing packaging, membranes, and barrier materials with controlled gas or vapor transmission rates.

Defining Permeability in Polymer Materials

Permeability in polymer materials refers to the rate at which a gas or liquid passes through a polymer film under a pressure gradient, combining the effects of both diffusivity and solubility within the material. It quantifies the material's ability to act as a barrier, impacting applications such as packaging, membranes, and protective coatings. Understanding permeability is crucial for selecting polymers with specific barrier properties tailored to environmental resistance and shelf-life requirements.

Understanding Diffusivity within Plastic Structures

Diffusivity in plastic structures refers to the rate at which molecules penetrate and move through the polymer matrix, influenced by factors such as polymer free volume, chain mobility, and temperature. Unlike permeability, which combines diffusivity and solubility to measure overall material transport, diffusivity solely quantifies molecular movement speed within the plastic. Understanding diffusivity enables precise control of gas or liquid barrier properties critical for packaging, medical devices, and membrane applications.

Key Differences: Permeability vs Diffusivity

Permeability in plastics measures the material's overall ability to allow gases or liquids to pass through it, combining both diffusivity and solubility factors. Diffusivity specifically quantifies the rate at which molecules spread through the polymer matrix due to concentration gradients, independent of solubility. Key differences lie in permeability representing the total transfer rate including absorption, while diffusivity isolates the molecular motion aspect within the plastic structure.

Factors Influencing Permeability in Plastics

Permeability in plastics is primarily influenced by factors such as polymer structure, temperature, and the size and solubility of permeating molecules. Higher crystallinity and denser polymer chains reduce permeability by limiting molecular mobility, while increased temperature generally enhances molecular diffusion and solubility, raising permeability rates. Understanding these factors helps you select plastics with appropriate barrier properties for specific applications involving gas or liquid transmission.

Determinants of Diffusivity in Polymer Films

Diffusivity in polymer films is primarily influenced by the polymer's free volume, chain mobility, and temperature, which determine how easily molecules traverse the polymer matrix. Molecular size and shape of the permeant also play a critical role, as smaller or more flexible molecules typically exhibit higher diffusion rates. The degree of crystallinity and crosslinking in the polymer structure further restricts segmental motion, reducing diffusivity in plastic materials.

Relationship Between Molecular Structure and Transport Properties

Permeability and diffusivity in plastics are intrinsically linked to the molecular structure, where polymer chain packing and free volume dictate gas or vapor transport rates. Higher fractional free volume and flexible chain segments typically enhance diffusivity, enabling faster molecular movement through the polymer matrix. Your selection of plastic materials should consider these structural factors to optimize barrier performance for specific applications.

Impact of Temperature and Environmental Conditions

Temperature and environmental conditions significantly influence permeability and diffusivity in plastics, as molecular mobility increases with rising temperature, enhancing both gas and vapor transport rates. Higher humidity and chemical exposure can swell polymer chains, altering free volume and increasing diffusivity, while reduced temperatures typically decrease permeability by restricting molecular movement. Understanding these effects allows you to predict material performance in varying service environments, optimizing plastic selection for specific applications.

Practical Applications: Packaging, Membranes, and Barriers

Permeability and diffusivity are critical parameters in plastics used for packaging, membranes, and barrier applications, directly influencing the material's ability to control gas and moisture transmission. In packaging, low permeability ensures extended shelf life by preventing oxygen and water vapor ingress, while membranes rely on selective diffusivity to separate gases or liquids efficiently. Understanding these properties helps you choose the right plastic for protective barriers that maintain product integrity and performance in various industrial and consumer environments.

Optimizing Plastic Performance Through Control of Permeability and Diffusivity

Optimizing plastic performance requires precise control over permeability and diffusivity, key parameters influencing gas and vapor transmission rates. Permeability quantifies the rate at which molecules pass through a plastic material, while diffusivity measures the speed of molecular movement within the polymer matrix. By tailoring polymer composition, crystallinity, and additive incorporation, manufacturers enhance barrier properties, improving applications in packaging, membranes, and protective coatings.

Permeability vs diffusivity (in plastics context) Infographic

libmatt.com

libmatt.com