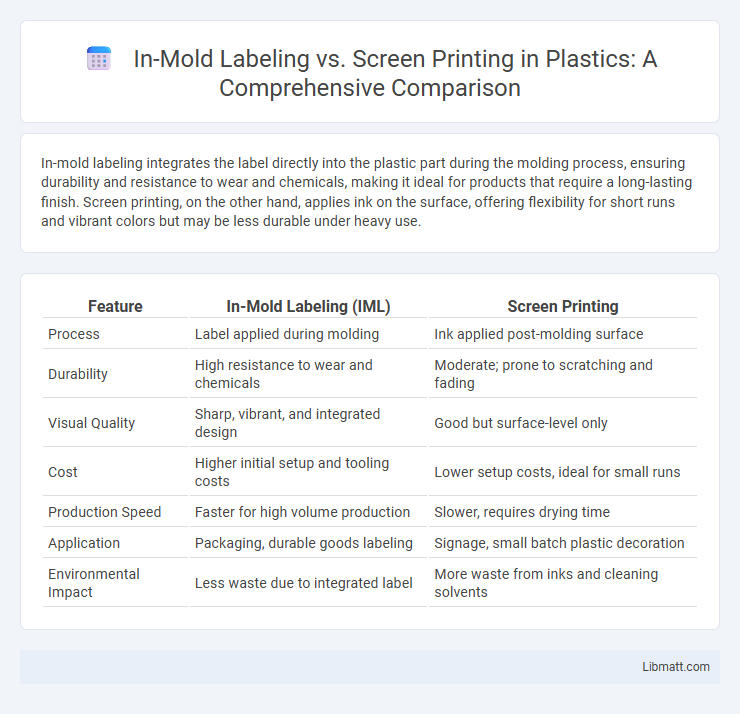

In-mold labeling integrates the label directly into the plastic part during the molding process, ensuring durability and resistance to wear and chemicals, making it ideal for products that require a long-lasting finish. Screen printing, on the other hand, applies ink on the surface, offering flexibility for short runs and vibrant colors but may be less durable under heavy use.

Table of Comparison

| Feature | In-Mold Labeling (IML) | Screen Printing |

|---|---|---|

| Process | Label applied during molding | Ink applied post-molding surface |

| Durability | High resistance to wear and chemicals | Moderate; prone to scratching and fading |

| Visual Quality | Sharp, vibrant, and integrated design | Good but surface-level only |

| Cost | Higher initial setup and tooling costs | Lower setup costs, ideal for small runs |

| Production Speed | Faster for high volume production | Slower, requires drying time |

| Application | Packaging, durable goods labeling | Signage, small batch plastic decoration |

| Environmental Impact | Less waste due to integrated label | More waste from inks and cleaning solvents |

Introduction to In-Mold Labeling and Screen Printing

In-mold labeling (IML) integrates high-quality graphics directly into plastic products during the injection molding process, ensuring durability and vibrant, long-lasting designs. Screen printing applies layers of ink through mesh screens onto surfaces, offering versatility in colors and textures but with less resistance to abrasion and fading. Both methods serve distinct purposes in product decoration, with IML excelling in seamless integration and screen printing favored for customization and cost efficiency on varied materials.

How In-Mold Labeling Works

In-Mold Labeling (IML) integrates pre-printed labels directly into plastic products during the molding process, ensuring a durable and seamless finish. The label, made of special polymers compatible with the mold material, is placed inside the mold before injecting molten plastic, which fuses the label and substrate into a single piece. This technique offers superior resistance to wear, chemicals, and fading compared to traditional screen printing methods.

The Screen Printing Process Explained

Screen printing involves applying ink directly onto a substrate through a mesh stencil, allowing for precise and vibrant designs. This process is highly versatile, supporting various materials like plastic, glass, and metal while accommodating complex color schemes. The durability of screen-printed labels makes them ideal for applications requiring long-lasting visual appeal and resistance to environmental factors.

Key Differences Between IML and Screen Printing

In-mold labeling (IML) integrates labels directly into the plastic molding process, creating a durable and seamless design, whereas screen printing applies ink onto the surface after molding, resulting in a more versatile but less wear-resistant finish. IML offers superior resistance to abrasion, fading, and chemical exposure, making it ideal for long-lasting branding on consumer products, while screen printing allows for quicker, cost-effective customization and a broader range of colors. Your choice depends on the need for durability and production scale, with IML excelling in high-volume, high-durability applications and screen printing suiting smaller, flexible runs.

Durability and Longevity Comparison

In-mold labeling offers superior durability and longevity compared to screen printing because the label becomes an integral part of the product's surface, resisting scratches, fading, and peeling even under harsh environmental conditions. Screen printing, although cost-effective for short runs, tends to wear off over time due to exposure to moisture, UV rays, and frequent handling. Your choice between these methods should consider the product's lifespan and exposure to physical or chemical stress to ensure lasting print quality.

Visual Quality and Design Flexibility

In-mold labeling offers superior visual quality with vibrant, high-resolution graphics that are permanently fused to the product surface, ensuring durability and resistance to wear and fading. Screen printing provides excellent design flexibility, allowing for custom colors, textures, and layering effects on various materials, but may experience diminished clarity and wear over time. Both methods accommodate unique design requirements, with in-mold labeling excelling in seamless integration and screen printing in creative customization.

Cost Analysis: IML vs. Screen Printing

In-mold labeling (IML) generally involves higher initial setup costs due to mold modifications and label production but offers lower per-unit costs for high-volume runs, making it cost-effective for large batches. Screen printing typically has lower startup expenses but higher per-unit costs with longer production times, which can increase expenses for complex or multi-color designs. Evaluating cost efficiency depends on production volume, design complexity, and long-term usage requirements, with IML favored for durability and consistency in mass production.

Environmental Impact and Sustainability

In-mold labeling significantly reduces waste by integrating labels directly into the molding process, eliminating the need for additional adhesives and separate label application, which decreases material usage and enhances recyclability. Screen printing generates more waste due to ink overspray, cleaning solvents, and excess materials, potentially contributing to environmental pollution. Choosing in-mold labeling supports sustainable manufacturing by minimizing hazardous waste and energy consumption compared to traditional screen printing methods.

Application Suitability and Industry Use Cases

In-mold labeling offers superior durability and a seamless finish ideal for packaging in food, beverage, and automotive industries where long-lasting graphics are essential. Screen printing excels in producing vibrant, customizable designs suited for promotional items, textiles, and electronics due to its cost-effectiveness and flexibility. Selecting between the two depends on production volume, environmental exposure, and the required aesthetic quality in specific industry applications.

Choosing the Right Labeling Method for Your Product

Selecting between In-Mold Labeling (IML) and Screen Printing depends on your product's durability, design complexity, and production volume. IML integrates the label into the product during molding, offering superior resistance to wear and chemicals, ideal for high-volume runs requiring vibrant, long-lasting graphics. Screen printing provides flexibility with color and texture options, suitable for lower volumes or intricate designs where tactile finishes enhance your product's appeal.

In-Mold Labeling vs Screen Printing Infographic

libmatt.com

libmatt.com