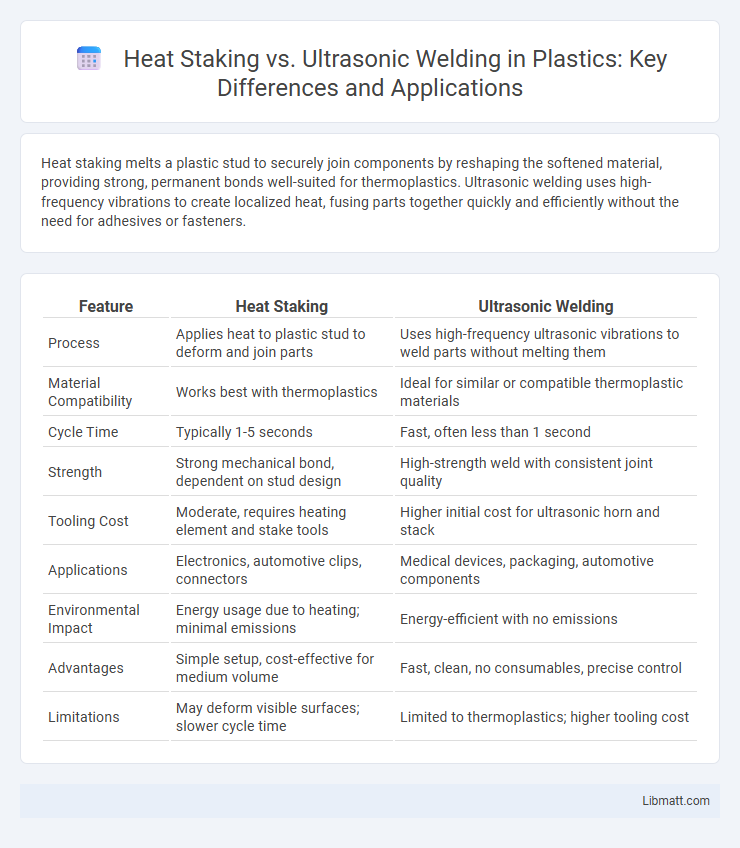

Heat staking melts a plastic stud to securely join components by reshaping the softened material, providing strong, permanent bonds well-suited for thermoplastics. Ultrasonic welding uses high-frequency vibrations to create localized heat, fusing parts together quickly and efficiently without the need for adhesives or fasteners.

Table of Comparison

| Feature | Heat Staking | Ultrasonic Welding |

|---|---|---|

| Process | Applies heat to plastic stud to deform and join parts | Uses high-frequency ultrasonic vibrations to weld parts without melting them |

| Material Compatibility | Works best with thermoplastics | Ideal for similar or compatible thermoplastic materials |

| Cycle Time | Typically 1-5 seconds | Fast, often less than 1 second |

| Strength | Strong mechanical bond, dependent on stud design | High-strength weld with consistent joint quality |

| Tooling Cost | Moderate, requires heating element and stake tools | Higher initial cost for ultrasonic horn and stack |

| Applications | Electronics, automotive clips, connectors | Medical devices, packaging, automotive components |

| Environmental Impact | Energy usage due to heating; minimal emissions | Energy-efficient with no emissions |

| Advantages | Simple setup, cost-effective for medium volume | Fast, clean, no consumables, precise control |

| Limitations | May deform visible surfaces; slower cycle time | Limited to thermoplastics; higher tooling cost |

Introduction to Heat Staking and Ultrasonic Welding

Heat staking uses controlled heat and pressure to deform a thermoplastic stud into a mechanical joint, ideal for assembling plastic-to-plastic or plastic-to-metal components. Ultrasonic welding employs high-frequency ultrasonic vibrations to create a solid-state weld by melting the interface between thermoplastic parts without additional adhesives or fasteners. Your manufacturing process benefits from selecting the method that best matches material compatibility, production speed, and joint strength requirements.

How Heat Staking Works

Heat staking works by applying controlled heat and pressure to thermoplastic components, causing localized melting of the plastic material. This process reshapes and deforms the plastic to form a mechanical joint that securely fastens parts together without the need for additional fasteners. The precision of temperature and time control ensures strong, consistent bonds ideal for assembling electronics, automotive parts, and consumer products.

How Ultrasonic Welding Works

Ultrasonic welding uses high-frequency ultrasonic vibrations to create a solid-state bond between thermoplastic materials or metal components without melting the base materials. The process involves applying pressure while ultrasonic energy generates localized frictional heat, causing the materials to fuse at the molecular level. This technique provides precise, clean, and strong joints with minimal thermal distortion, making it ideal for delicate electronic assemblies compared to heat staking.

Key Differences Between Heat Staking and Ultrasonic Welding

Heat staking uses controlled heat and pressure to join thermoplastic components by softening the material, while ultrasonic welding employs high-frequency ultrasonic vibrations to create frictional heat that fuses parts together. Heat staking is ideal for applications requiring a strong, vibration-resistant bond without additional fasteners, whereas ultrasonic welding offers faster cycle times and precise, clean joints suitable for mass production. Your choice between these methods depends on factors such as material compatibility, production volume, and desired joint strength.

Material Compatibility for Each Joining Method

Heat staking works best with thermoplastic materials, allowing for precise deformation and strong mechanical bonding by melting and reshaping the plastic studs. Ultrasonic welding suits a broader range of materials, including thermoplastics and some metals, by using high-frequency vibrations to create a solid-state weld through localized melting. Your choice between these methods depends on the specific materials involved and the desired strength and quality of the joint.

Typical Applications in Industry

Heat staking is commonly used for assembling thermoplastic components in industries such as automotive, electronics, and medical devices, where precise control and strong, vibration-resistant joints are essential. Ultrasonic welding finds widespread application in electrical and electronic manufacturing, packaging, and textiles, enabling rapid, clean, and strong bonds without adhesives or fasteners. Both methods optimize production efficiency in high-volume manufacturing environments requiring durable plastic assemblies.

Advantages of Heat Staking

Heat staking offers precise control over joining plastic components by applying heat and pressure, resulting in strong, durable bonds without the need for additional adhesives or fasteners. This method accommodates a wide range of thermoplastic materials and complex geometries, enhancing design flexibility and reducing cycle times. Heat staking also minimizes the risk of material damage and enables cost-effective automation in high-volume manufacturing processes.

Advantages of Ultrasonic Welding

Ultrasonic welding offers rapid cycle times and energy efficiency, making it ideal for high-volume production runs. This process creates strong, consistent bonds without the need for additional materials or adhesives, ensuring cleaner assembly. Your manufacturing can benefit from reduced thermal stress on components and minimal distortion compared to heat staking.

Limitations and Challenges of Both Techniques

Heat staking faces limitations such as longer cycle times and potential thermal damage to delicate components, making it less suitable for heat-sensitive materials. Ultrasonic welding challenges include the need for precise joint design, limitations with thicker or rigid plastics, and sensitivity to variations in material composition that can impact weld quality. Your choice between these methods should consider part geometries, material properties, and production volume constraints to minimize defects and ensure robust bonding.

Choosing the Right Method for Your Project

When selecting between heat staking and ultrasonic welding, consider the material types and production volume of your project. Heat staking is ideal for thermoplastics, providing strong mechanical bonds through localized melting, while ultrasonic welding excels in joining thin or delicate components quickly without adhesives. Understanding your project's durability requirements and manufacturing speed helps you determine the most efficient and reliable method.

Heat staking vs ultrasonic welding Infographic

libmatt.com

libmatt.com