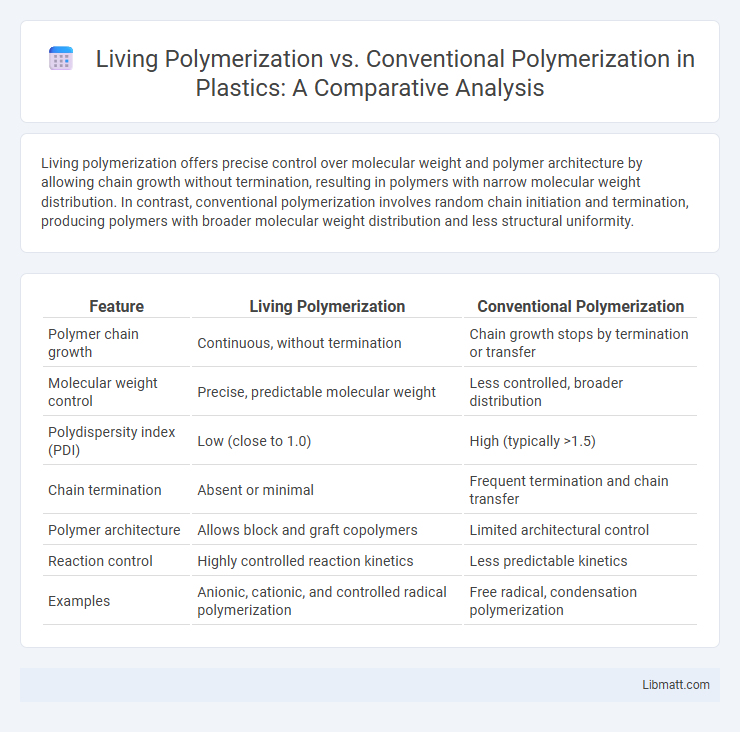

Living polymerization offers precise control over molecular weight and polymer architecture by allowing chain growth without termination, resulting in polymers with narrow molecular weight distribution. In contrast, conventional polymerization involves random chain initiation and termination, producing polymers with broader molecular weight distribution and less structural uniformity.

Table of Comparison

| Feature | Living Polymerization | Conventional Polymerization |

|---|---|---|

| Polymer chain growth | Continuous, without termination | Chain growth stops by termination or transfer |

| Molecular weight control | Precise, predictable molecular weight | Less controlled, broader distribution |

| Polydispersity index (PDI) | Low (close to 1.0) | High (typically >1.5) |

| Chain termination | Absent or minimal | Frequent termination and chain transfer |

| Polymer architecture | Allows block and graft copolymers | Limited architectural control |

| Reaction control | Highly controlled reaction kinetics | Less predictable kinetics |

| Examples | Anionic, cationic, and controlled radical polymerization | Free radical, condensation polymerization |

Introduction to Polymerization Methods

Living polymerization offers precise control over molecular weight and polymer architecture by allowing chain growth without termination reactions, unlike conventional polymerization where chain termination and transfer limit molecular uniformity. Techniques such as anionic, cationic, and controlled radical polymerization exemplify living polymerization, enabling synthesis of block copolymers and complex structures. Conventional polymerization methods, including free radical, condensation, and step-growth polymerization, often result in broader molecular weight distributions and less control over polymer chain ends.

Overview of Conventional Polymerization

Conventional polymerization involves chain-growth or step-growth processes where polymer chains terminate once monomers are consumed or chain-stopping agents interfere, resulting in broad molecular weight distribution and less control over polymer architecture. In these reactions, free radicals, cations, or anions initiate polymerization, but the process lacks the ability to regulate chain length precisely. Understanding the limitations of conventional polymerization is essential when comparing it to living polymerization, which offers enhanced control and uniformity in polymer synthesis.

Fundamentals of Living Polymerization

Living polymerization fundamentally differs from conventional polymerization by preventing chain termination and chain transfer reactions, enabling continuous growth of polymer chains. This process allows precise control over molecular weight distribution and polymer architecture, which is critical for synthesizing block copolymers, star polymers, and other complex structures. Your ability to tailor polymers at the molecular level hinges on understanding these mechanisms that maintain active chain ends throughout the reaction.

Key Differences: Living vs Conventional Polymerization

Living polymerization allows precise control over molecular weight and polymer architecture by preventing chain termination and transfer reactions, resulting in narrow molecular weight distributions. Conventional polymerization involves chain termination and transfer, leading to broader molecular weight distributions and less control over polymer structure. Your choice between these methods influences polymer uniformity, functionalization, and application-specific performance.

Mechanisms and Kinetics Comparison

Living polymerization features a chain-growth mechanism where active centers remain reactive without termination, enabling precise control over molecular weight and polymer architecture. Conventional polymerization involves radical or ionic mechanisms with termination and chain-transfer steps, leading to broader molecular weight distributions and less uniform polymer structures. Kinetically, living polymerization exhibits constant active species concentration, resulting in linear molecular weight growth, while conventional polymerization shows complex kinetics due to competing propagation and termination reactions.

Molecular Weight Control in Both Methods

Living polymerization provides precise molecular weight control by allowing polymer chains to grow without termination or chain transfer reactions, resulting in polymers with narrow molecular weight distributions. Conventional polymerization often exhibits broader molecular weight distributions due to random chain termination and transfer events that limit control over polymer chain length. Your ability to tailor polymer properties is enhanced with living polymerization techniques due to the predictable and uniform molecular weights achievable.

Polymer Architecture and Structural Precision

Living polymerization enables precise control over polymer architecture, allowing for well-defined block, graft, and star polymers with narrow molecular weight distributions. Conventional polymerization often results in broader molecular weight distributions and less control over polymer structure due to chain termination and transfer reactions. You can achieve superior structural precision and tailored polymer architectures using living polymerization techniques.

Common Applications and End-Use Products

Living polymerization is widely used in producing precision polymers for advanced applications such as drug delivery systems, specialty coatings, and electronic materials due to its ability to control molecular weight and architecture. Conventional polymerization dominates in manufacturing everyday products like packaging films, automotive parts, and household goods because of its cost-effectiveness and scalability. Your choice between the two methods impacts product performance, with living polymerization offering enhanced functionality for high-tech uses and conventional polymerization meeting broad market demands.

Advantages of Living Polymerization Over Conventional Methods

Living polymerization offers precise control over molecular weight and polymer architecture, enabling the synthesis of polymers with narrow molecular weight distributions. It allows for the creation of block copolymers and architecturally complex polymers without termination or chain transfer reactions, which are common drawbacks in conventional polymerization. The ability to regulate polymer chain growth enhances reproducibility and functionalization potential, making living polymerization highly advantageous for advanced material design.

Future Trends in Polymerization Techniques

Living polymerization is poised to revolutionize the future of polymer science by enabling precise control over molecular weight and polymer architecture, surpassing the limitations of conventional polymerization methods. Innovations in controlled radical and ring-opening polymerizations allow for tailored materials with enhanced properties for applications in biomedicine, electronics, and sustainable packaging. Your ability to harness these cutting-edge techniques will drive the development of advanced polymers with customizable functionalities and minimal environmental impact.

Living polymerization vs conventional polymerization Infographic

libmatt.com

libmatt.com