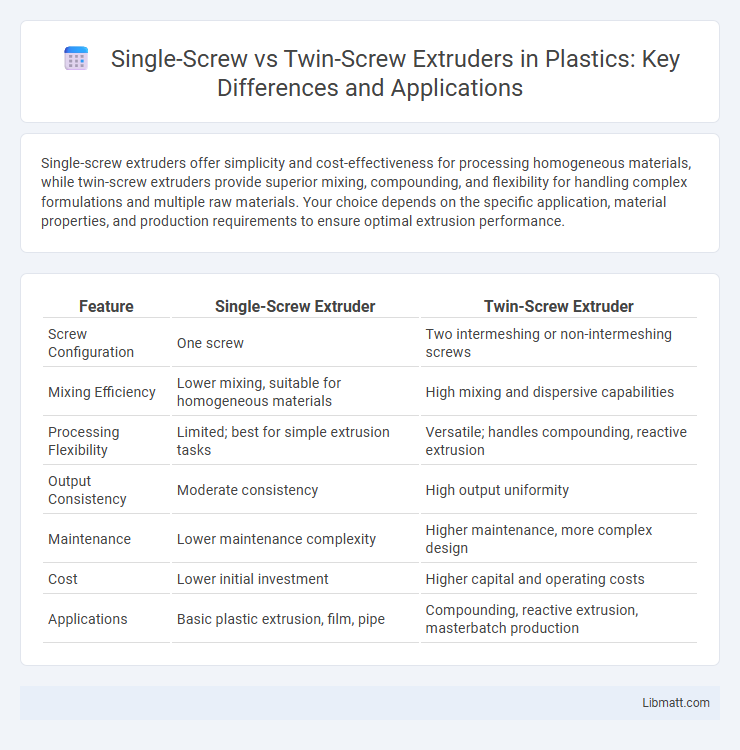

Single-screw extruders offer simplicity and cost-effectiveness for processing homogeneous materials, while twin-screw extruders provide superior mixing, compounding, and flexibility for handling complex formulations and multiple raw materials. Your choice depends on the specific application, material properties, and production requirements to ensure optimal extrusion performance.

Table of Comparison

| Feature | Single-Screw Extruder | Twin-Screw Extruder |

|---|---|---|

| Screw Configuration | One screw | Two intermeshing or non-intermeshing screws |

| Mixing Efficiency | Lower mixing, suitable for homogeneous materials | High mixing and dispersive capabilities |

| Processing Flexibility | Limited; best for simple extrusion tasks | Versatile; handles compounding, reactive extrusion |

| Output Consistency | Moderate consistency | High output uniformity |

| Maintenance | Lower maintenance complexity | Higher maintenance, more complex design |

| Cost | Lower initial investment | Higher capital and operating costs |

| Applications | Basic plastic extrusion, film, pipe | Compounding, reactive extrusion, masterbatch production |

Introduction to Extrusion Technology

Extrusion technology involves the continuous shaping of materials by forcing them through a die, with single-screw and twin-screw extruders serving distinct roles. Single-screw extruders excel in melting and conveying uniform materials, offering simplicity and cost-effectiveness for standard applications. Twin-screw extruders provide enhanced mixing and compounding capabilities, making them ideal for complex formulations and processing high-viscosity or multiple-component materials in Your manufacturing processes.

Overview of Single-Screw Extruders

Single-screw extruders feature one rotating screw within a heated barrel, primarily used for melting, mixing, and shaping thermoplastic materials. These extruders excel in simplicity, cost-effectiveness, and ease of maintenance, making them ideal for applications like film, sheet, and pipe production. Their design typically limits processing flexibility and mixing efficiency compared to twin-screw extruders, but they remain predominant in high-volume, uniform melt processing.

Overview of Twin-Screw Extruders

Twin-screw extruders feature two intermeshing screws rotating inside a barrel, enabling superior mixing, compounding, and precise temperature control compared to single-screw extruders. This design enhances material homogeneity and shear control, making them ideal for complex polymer processing, food production, and reactive extrusion applications. Their modular construction allows customization for specific processing needs, improving efficiency and product quality.

Key Design Differences

Single-screw extruders feature a solitary screw within a barrel, primarily designed for melting, mixing, and conveying materials, making them ideal for simpler processes with lower output requirements. Twin-screw extruders incorporate two intermeshing screws that provide superior mixing, consistent shear, and better temperature control, enhancing process flexibility and efficiency for complex or high-demand applications. Your choice between single-screw and twin-screw extruders depends on the specific material handling, mixing precision, and production capacity needed.

Processing Capabilities Comparison

Single-screw extruders excel in processing homogeneous materials with consistent viscosity, ideal for simple compounding and melting applications. Twin-screw extruders offer superior mixing, precise temperature control, and better handling of complex formulations, including reactive extrusion and multi-component blending. Your choice hinges on the processing complexity, with twin-screw units providing enhanced versatility and efficiency for advanced material processing.

Material Compatibility and Versatility

Single-screw extruders excel in processing homogenous, heat-sensitive materials like thermoplastics and offer cost-effective, straightforward operations. Twin-screw extruders provide superior versatility by handling a wider range of materials, including composites, fillers, and reactive compounds, ensuring enhanced mixing and processing control. Your choice depends on the specific material compatibility requirements and desired processing flexibility.

Operational Efficiency and Output

Single-screw extruders offer simplicity and cost-effectiveness with moderate operational efficiency, ideal for processing homogeneous materials at lower output volumes. Twin-screw extruders provide superior mixing, precise control, and higher throughput, enhancing operational efficiency for complex formulations and large-scale production. When maximizing Your output and product consistency is critical, twin-screw extruders typically deliver greater performance and flexibility.

Cost Analysis and Investment Considerations

Single-screw extruders generally have lower initial costs and simplified maintenance, making them ideal for low to medium production volumes and less complex materials. Twin-screw extruders, though requiring a higher upfront investment, offer superior mixing capabilities and processing flexibility, justifying their cost in applications demanding precise control and high throughput. Businesses must weigh the trade-off between capital expenditure and operational efficiency, considering long-term production goals and material specifications before choosing between the two.

Applications in Various Industries

Single-screw extruders are widely used for processing thermoplastics, rubber, and food products, making them ideal for industries like packaging, automotive, and agriculture due to their simplicity and efficiency. Twin-screw extruders excel in compounding, reactive extrusion, and producing uniform blends, making them crucial in pharmaceuticals, plastics compounding, and food processing industries where precise control and high shear are needed. Your choice depends on the required processing capabilities, material properties, and product complexity for optimal industrial application.

Choosing the Right Extruder for Your Needs

Selecting the right extruder depends on your processing requirements and material characteristics. Single-screw extruders are ideal for simple, high-volume production of thermoplastics, offering lower cost and ease of maintenance. Twin-screw extruders excel in handling complex compounds, providing superior mixing, precise temperature control, and better performance with additives or fillers, making them suitable for specialized applications where product consistency is critical.

Single-Screw Extruder vs Twin-Screw Extruder Infographic

libmatt.com

libmatt.com